A method for improving high-temperature and high-salt properties of iron powder by using plasma electrolysis

A plasma electrolysis, high temperature and high salt technology, applied in electrolytic inorganic material coating, metal processing equipment, transportation and packaging, etc. It is easy to completely and uniformly coat problems, and achieve the effect of simplifying the powder modification process, improving the high temperature and high salt performance of iron powder, and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

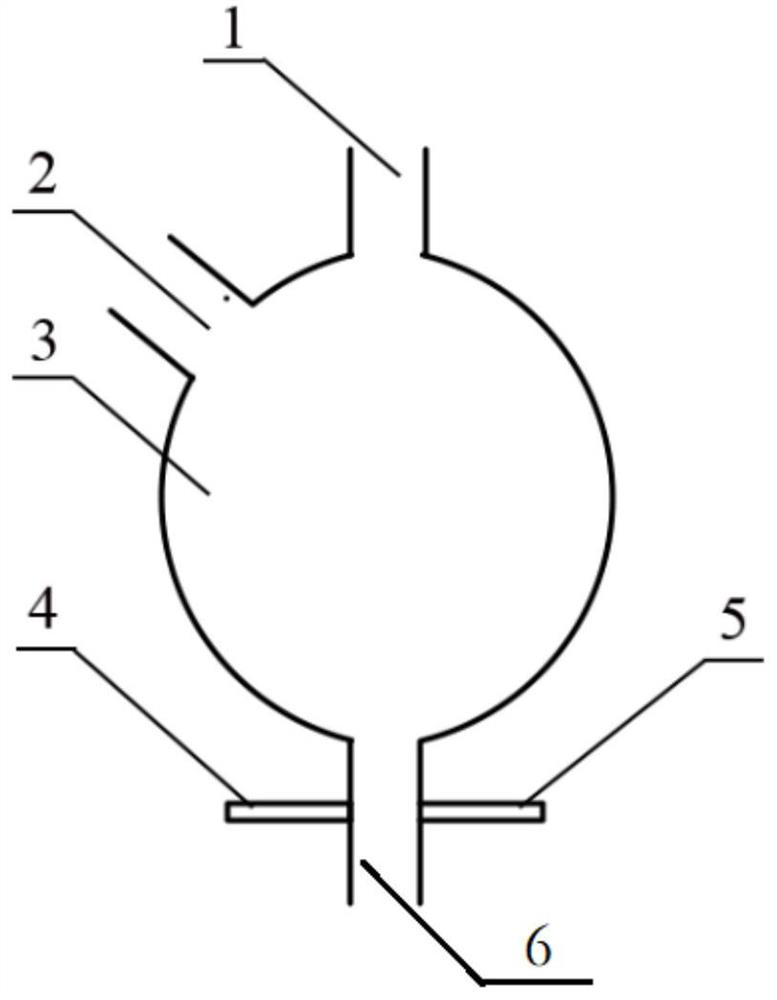

[0028] (1) The liquid feed port 2 at the upper end of the mixing vessel is connected with the source of the electrolytic solution, and the solid feed port 1 at the upper end of the mixing vessel is connected with the source of iron powder; wherein the source of the electrolytic solution is 10L of Na with a concentration of 30g / L 2 SiO 3 Aqueous solution, the source of iron powder is 500g of carbonyl iron powder with a particle size of 10 μm;

[0029] (2) The negative electrode 5 and the positive electrode 4 are symmetrically installed on the side wall of the discharge port 6 at the lower end of the mixing container, and the end faces of the negative electrode 5 and the positive electrode 4 are respectively connected to the inner surface of the side wall of the corresponding discharge port 6 flush, the cathode electrode 5 and the anode electrode 4 are respectively connected to a high-frequency DC power supply; wherein, the cathode electrode is a titanium alloy rod with a diamet...

Embodiment 2

[0034] (1) The liquid feed port 2 at the upper end of the mixing vessel is connected with the source of the electrolytic solution, and the solid feed port 1 at the upper end of the mixing vessel is connected with the source of iron powder; wherein the source of the electrolytic solution is 10L of Na with a concentration of 50g / L 2 SiO 3 Aqueous solution, iron powder source is 3000g flake iron powder with a particle size of 30μm;

[0035] (2) The negative electrode 5 and the positive electrode 4 are symmetrically installed on the side wall of the discharge port 6 at the lower end of the mixing container, and the end faces of the negative electrode 5 and the positive electrode 4 are respectively connected to the inner surface of the side wall of the corresponding discharge port 6 The cathode electrode 5 and the anode electrode 4 are respectively connected to a high-frequency DC power supply; among them, the cathode electrode is selected from a M6 titanium alloy rod with a diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com