In-Line Cutting or Marking System for Rotating Laser Masks in Ring Ribbon

A mask and ribbon technology, applied in the field of laser cutting and engraving, can solve the problems of pattern deformation, inaccessibility of laser technology, restricting the increase of equipment productivity, etc., to eliminate the deformation of cutting or engraving patterns, improve the speed of laser cutting and engraving, The effect of simplifying drive control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

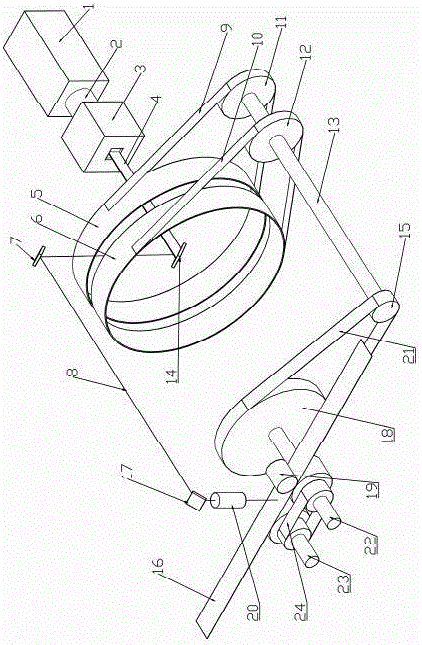

[0037] Example 1: Cutting or marking system for cylindrical rotary mask

[0038] see figure 1, This embodiment consists of a laser unit, two cylindrical masks arranged side by side coaxially, the first mask 5, the second mask 6, an optical path assembly, and a drive and transmission unit.

[0039] The laser unit includes a laser light source 1 , a light source interface 2 and a laser beam expansion and shaping unit 3 . The laser light source can be YAG or CO2 laser source, and its intensity can be selected according to the material properties, thickness, transmission speed and other parameters of the material to be processed. The laser light source can continuously adjust the intensity during operation, and the external trigger laser emission or shutdown. The emitting end of the laser light source 1 has a threaded bayonet threaded connection with the light source interface 2, and the other end of the light source interface 2 is connected with the laser beam expanding and shap...

Embodiment 2

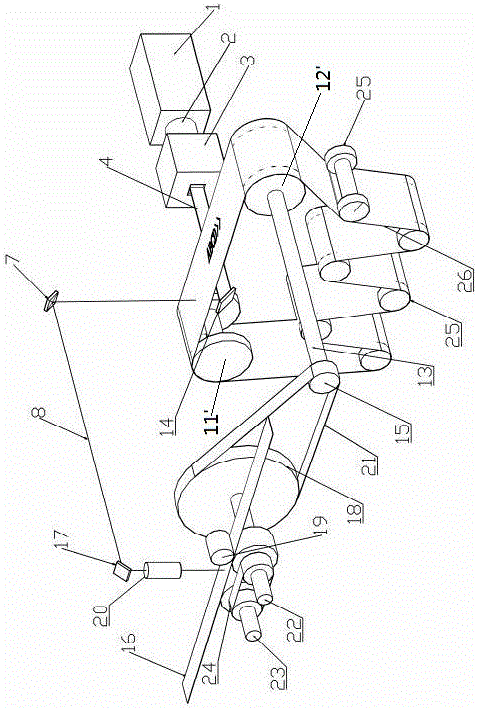

[0048] Embodiment 2: An on-line cutting or marking system for an annular belt-shaped rotatable laser mask.

[0049] see figure 2 , This embodiment is composed of a laser part, a tape mask 26, an optical path assembly, and a driving and transmission part. The structure of the laser part and the optical path assembly is the same as that of Embodiment 1. The structural arrangement relationship of the transmission components at the processing end is also the same as that of Embodiment 1. The transmission mechanism includes the first mask end synchronous pulley 11', the second mask end synchronous pulley 12', six middle mask transmission wheels 25, the transmission shaft 13, the first processing end synchronous pulley 18, the second processing End synchronous pulley 15, first processing end synchronous belt 21, first processing end transmission shaft 22, second processing end transmission shaft 23 arranged in parallel, first processing end transmission shaft 22 or second process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com