Resin flow zone control method in composite material component

A composite material component and composite material technology, which is applied in the field of resin flow partition control in composite material components, can solve problems such as difficult control of resin flow, and achieve the effect of solving serious uneven curing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

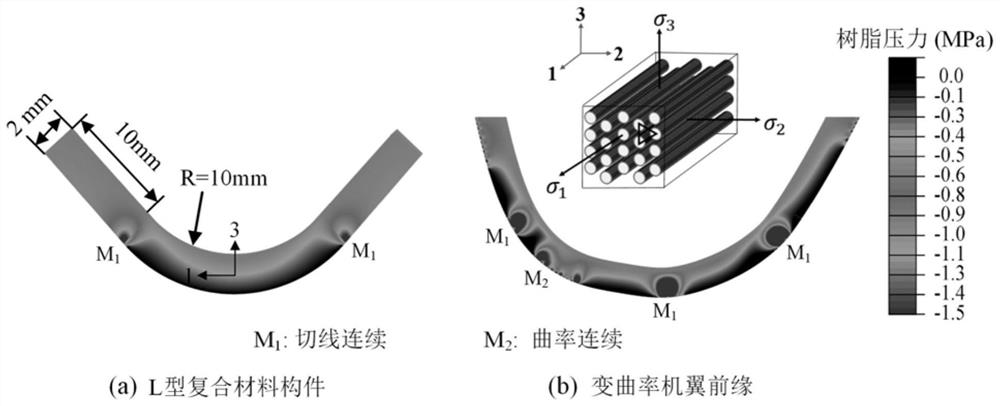

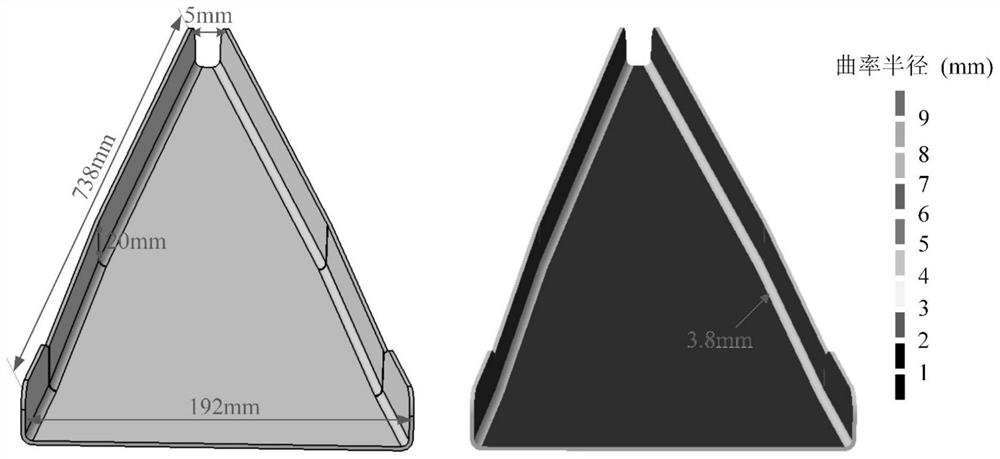

[0035]The embodiment of the present invention is described by taking a typical variable-section aircraft composite material component as an example. The length of the component is 738mm, the height is 20mm, and the thickness is 2mm. The section width decreases from 192mm to 5mm with the length, such as image 3 shown. By analyzing the resin pressure distribution of the component, according to the first partition criterion, the component is divided into 5 areas: 2 arc areas and 3 plane areas. According to the second division criterion, the radius of curvature corresponding to the resin pressure threshold is 27mm, and the radius of curvature of the two arcs is 3.8mm, both of which are lower than 27mm. There is no need to divide the already divided areas. The final division result of this component is 5 areas.

[0036] Microfluidic valves are arranged at the boundaries of the five regions to limit the mutual flow of resin between different regions. Two rows of micropores with a...

example 2

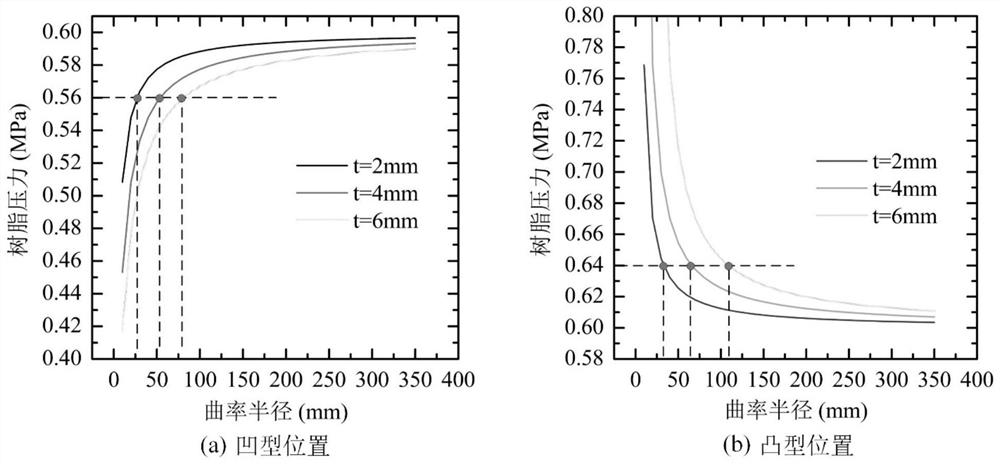

[0038] The difference between this example and Example 1 is that the resin pressure in the profile of the composite component is continuous, and after the first partition criterion is invalid, the profile surface is continued to be divided according to the second partition criterion. Component shape such as Figure 4 As shown, the thickness of the composite material is 2 mm. According to the content of the invention, if the resin pressure loss of 0.04 MPa is used as the threshold value, the corresponding radius of curvature at the concave position is 27 mm, and the corresponding radius of curvature at the convex position is 35 mm. According to the second division criterion, the The component is finally divided into 9 areas, and the rest are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com