Scroll type compressor

一种涡旋压缩机、涡旋的技术,应用在涡旋压缩机领域,能够解决加工困难、螺旋状通路加工精度要求高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

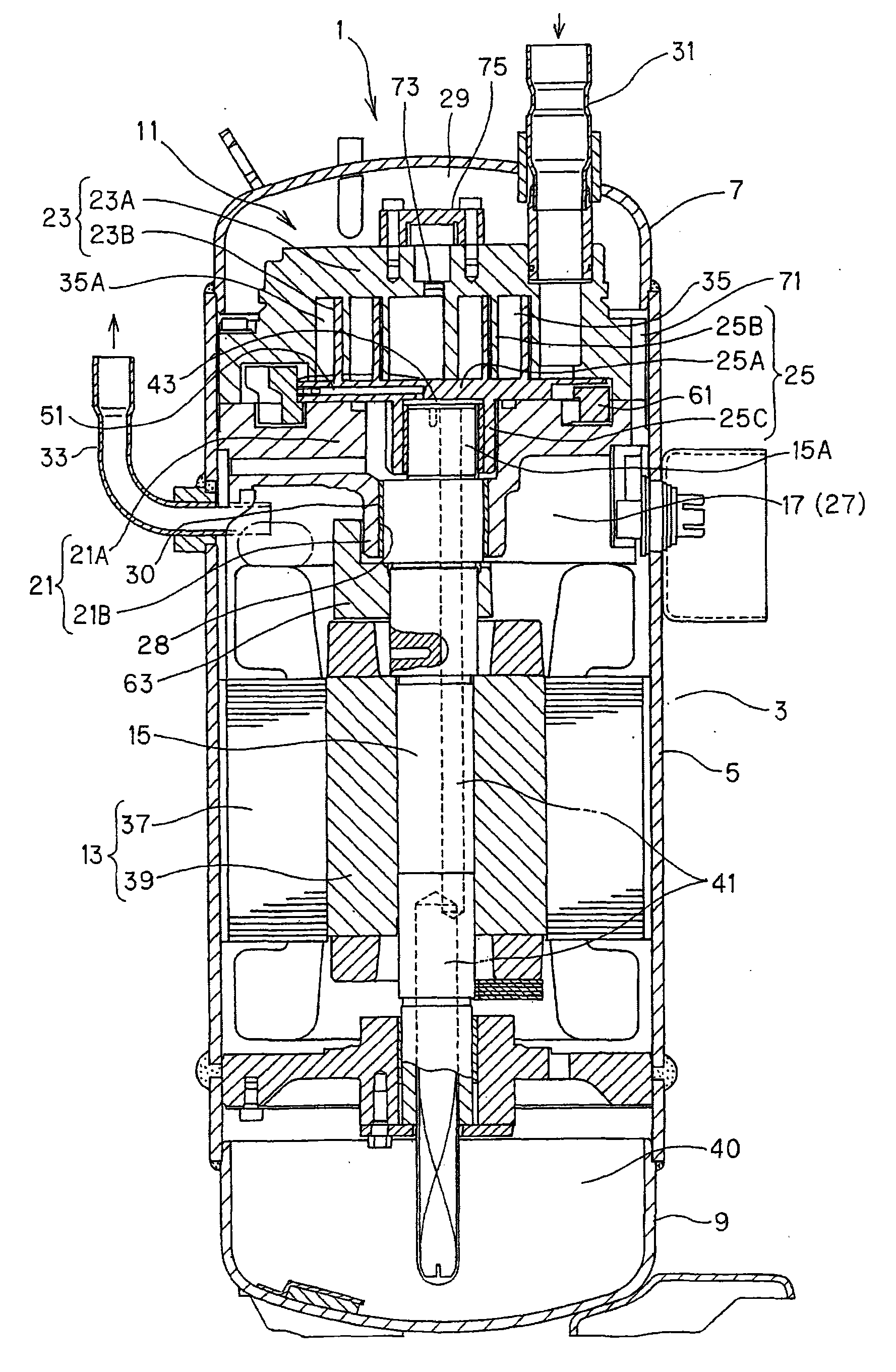

[0027] Hereinafter, one embodiment of the present invention will be described based on the drawings.

[0028] exist figure 1 Among them, reference numeral 1 denotes a scroll compressor constituting an internal high pressure, and the compressor 1 is connected to a refrigerant circuit outside the figure, and is used to compress refrigerant, and the refrigerant circulates in the refrigerant circuit to perform refrigeration cycle operation . This compressor 1 has a vertically elongated cylindrical hermetic dome casing 3 .

[0029] The shell 3 is composed of a shell body 5, a bowl-shaped upper cover 7, and a bowl-shaped lower cover 9 to form a pressure vessel, and a cavity is formed inside. The housing body 5 is a cylindrical base part with an axis extending in the up-down direction; the upper cover 7 is integrally welded to the upper end of the housing body 5 in an airtight manner, and has a convex surface protruding upward; the lower The cover 9 is integrally welded to the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com