Mechanism of agricultural swirl nozzle based on magnetorheological fluid micro-motion variable pressure

A technology of magnetorheological fluid and swirl nozzle, applied in the direction of application, injection device, injection device, etc., can solve the problems of inconvenient and precise, cumbersome structure and control, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

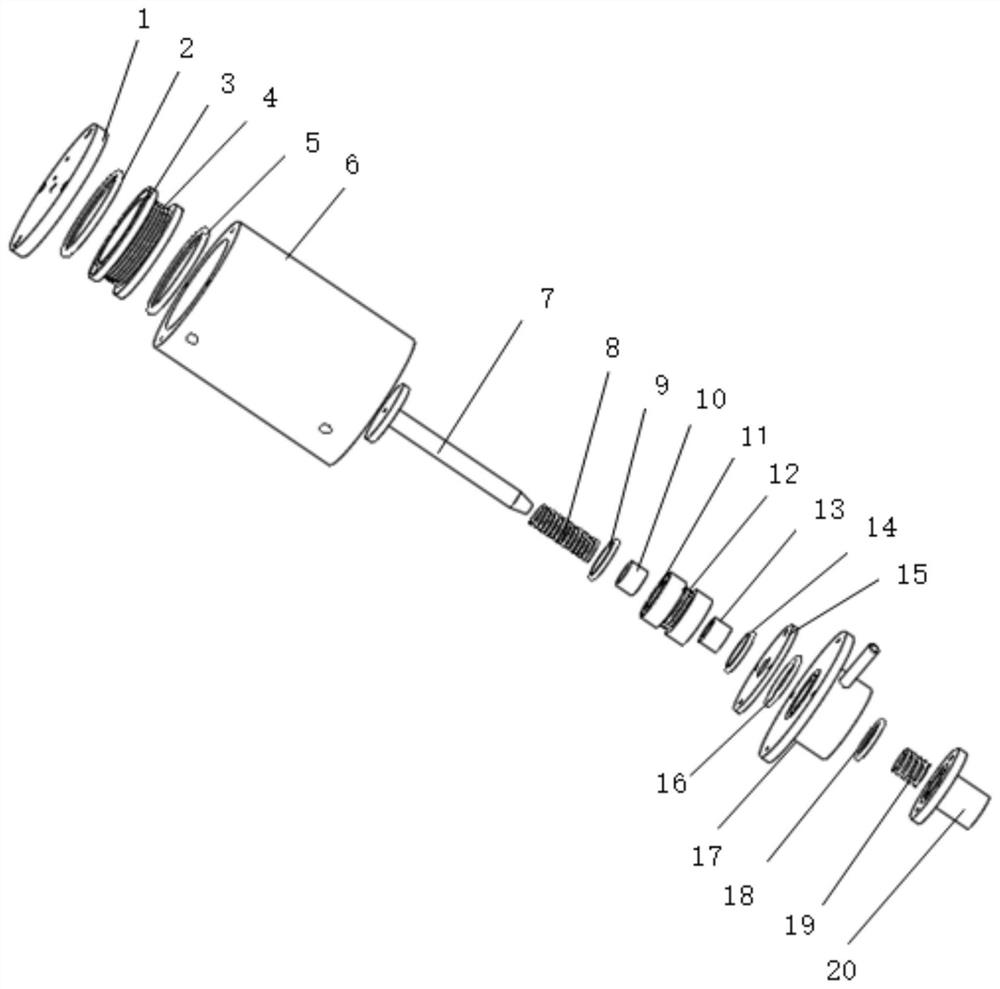

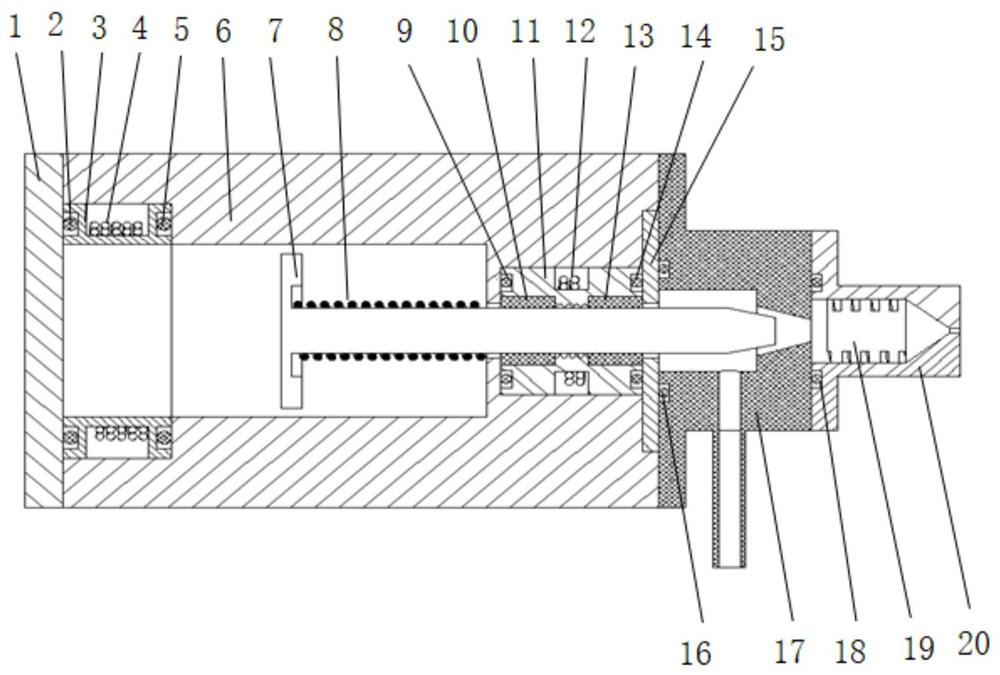

[0020] Such as figure 1 , 2 As shown, the present invention is based on the magnetorheological fluid micro-variable pressure-variable agricultural swirl nozzle mechanism, including sub-assembly magnetorheological fluid variable push rod and sub-assembly swirl nozzle structure.

[0021] The magnetorheological fluid variable push rod includes a first cover plate 1, a magnetorheological fluid bearing chamber 6, a plurality of O-rings, a spacer 3, a first energized coil 4, a second energized coil 12, and a variable pressure push rod 7. The return spring 8, the sealing spacer 11, the copper sleeve 13 and the second cover plate 15, the magnetorheological fluid is loaded in the magnetorheological fluid bearing chamber, and a plurality of O-rings include O-rings 2, O-type Sealing ring 5, O-ring 9 and O-ring 14. Wherein, the spacer 3 is installed in the rear end column hole of the magnetorheological fluid bearing cavity 6, and the first energized coil is wound on the spacer and passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com