Torpedo needle

A torpedo needle and core technology, applied in the field of torpedo needles, can solve the problems of insufficient cooling of high-temperature molten materials, inability to effectively limit the flow of molten materials, and affect product quality, etc., to achieve simple design, prevent drooling and drawing, and fully cool Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described below in conjunction with accompanying drawing.

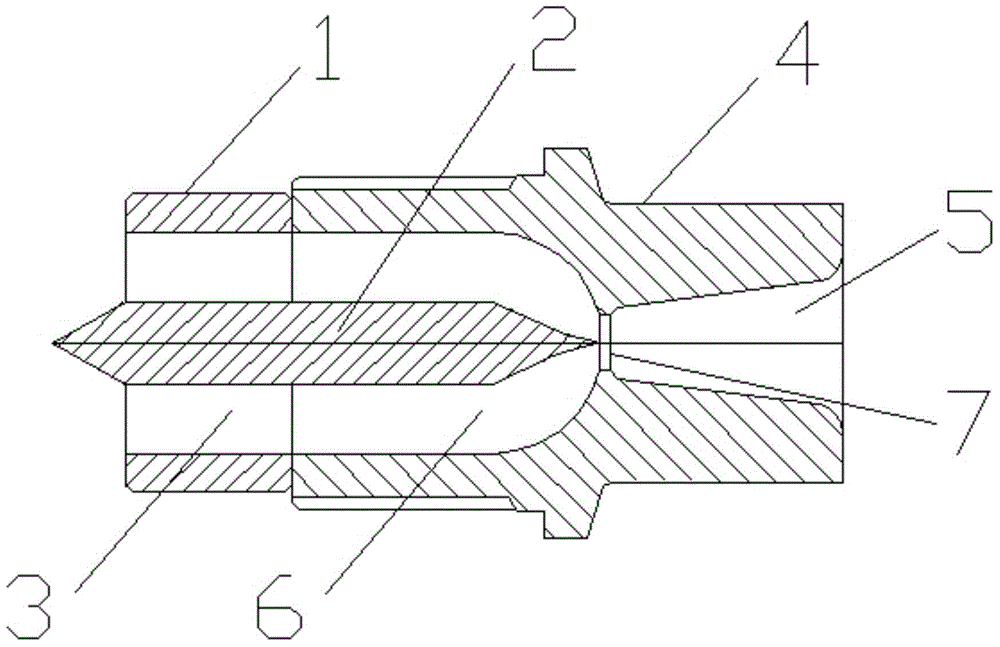

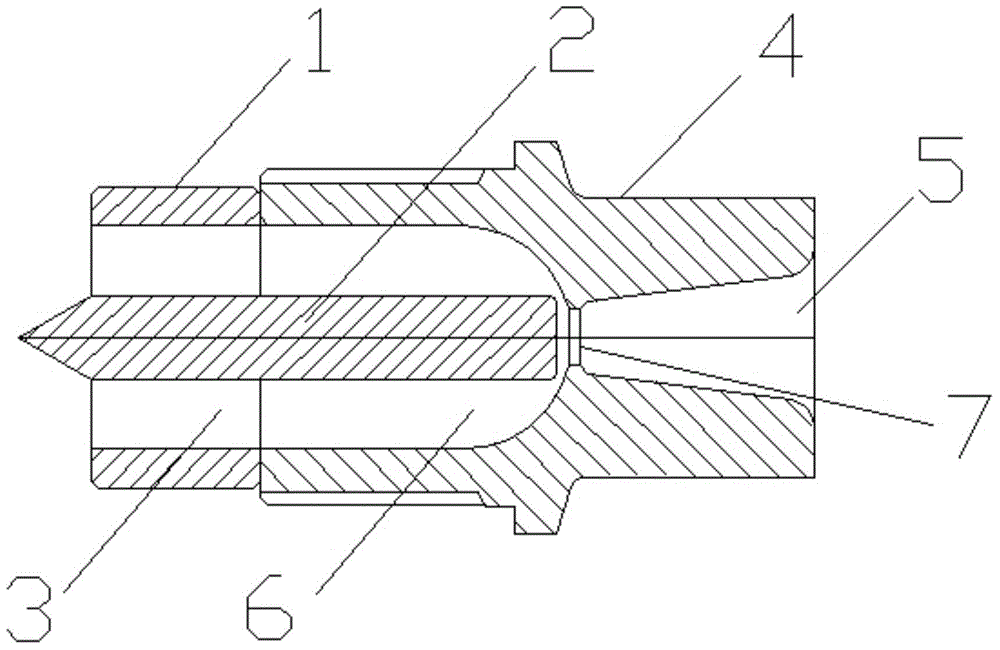

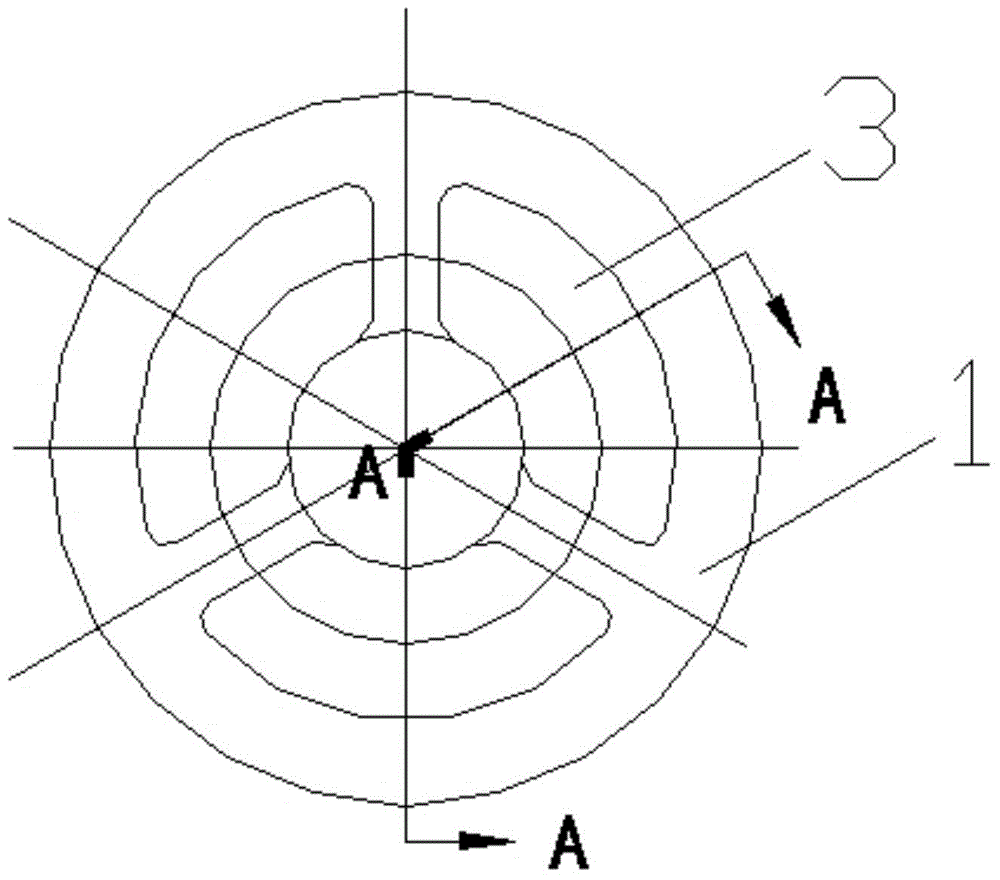

[0018] as attached Figure 2-5 Shown is a kind of torpedo needle of the present invention, comprises core umbrella head 1, core rod 2 and fixed cover 4; One end of described fixed cover 4 is provided with glue port 5 at the center, and described glue port 5 is Conical outward expansion; the center of the other end of the fixed cover 4 is provided with a fixed cover inner cavity 6; the fixed cover inner cavity 6 communicates with the glue port 5 through the inner cavity hole 7; A feed chamber 3 is provided; the core rod 2 is arranged at the center of the core umbrella head 1; one end of the core rod 2 is a flat end, and the other end is a pointed end; the core rod 2 extends into the inner cavity 6 of the fixed cover; the flat end is located inside the inner cavity 6 of the fixed cover; the flat end cooperates with the inner cavity hole 7, so that the molten material with a suitable flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com