Sand screening device applied to road and bridge construction

A screening device and bridge construction technology, which is applied in the direction of screening, separating solids from solids by air flow, and solids separation, etc., can solve the problems of wasting manpower and laborious screening operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

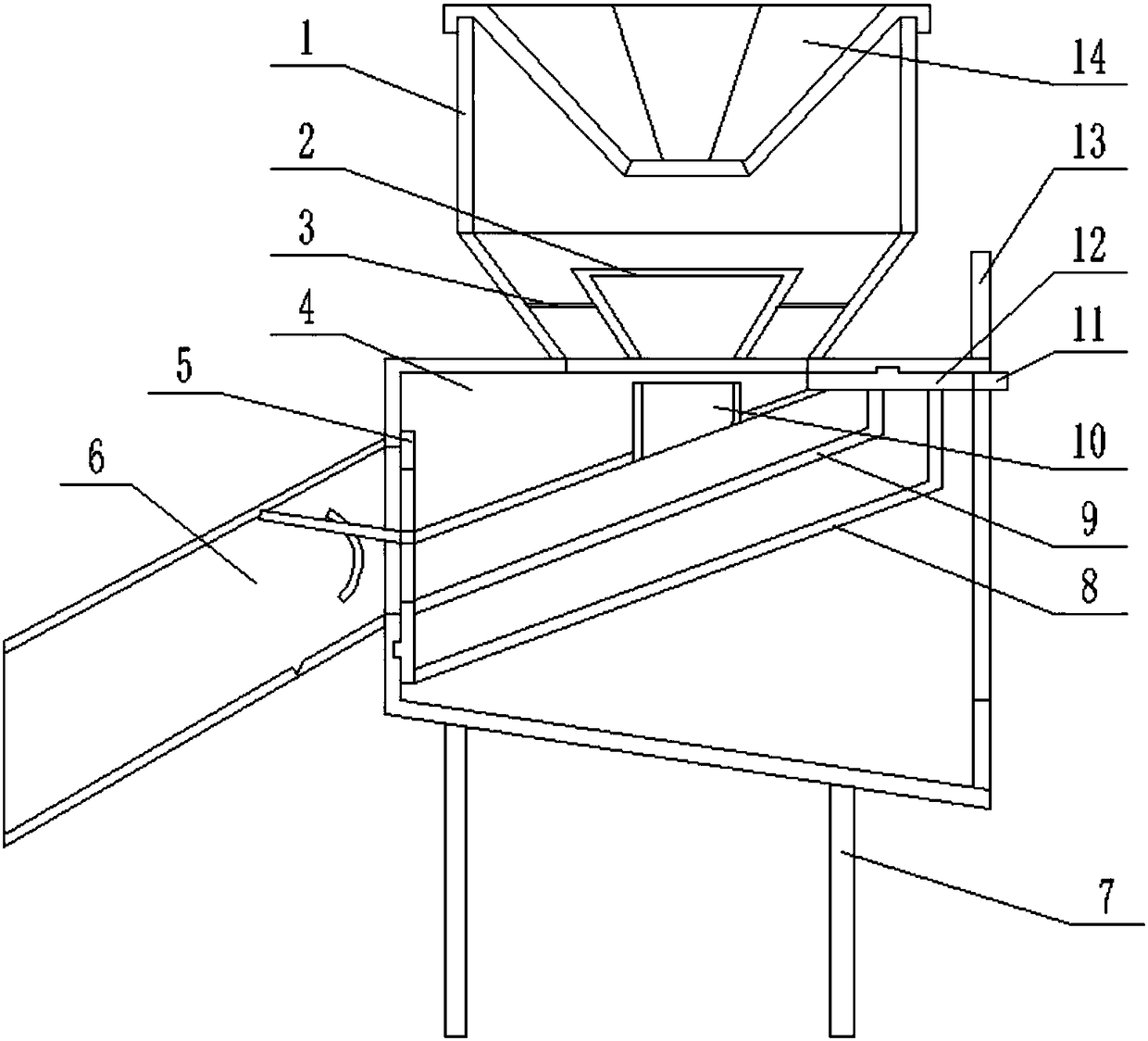

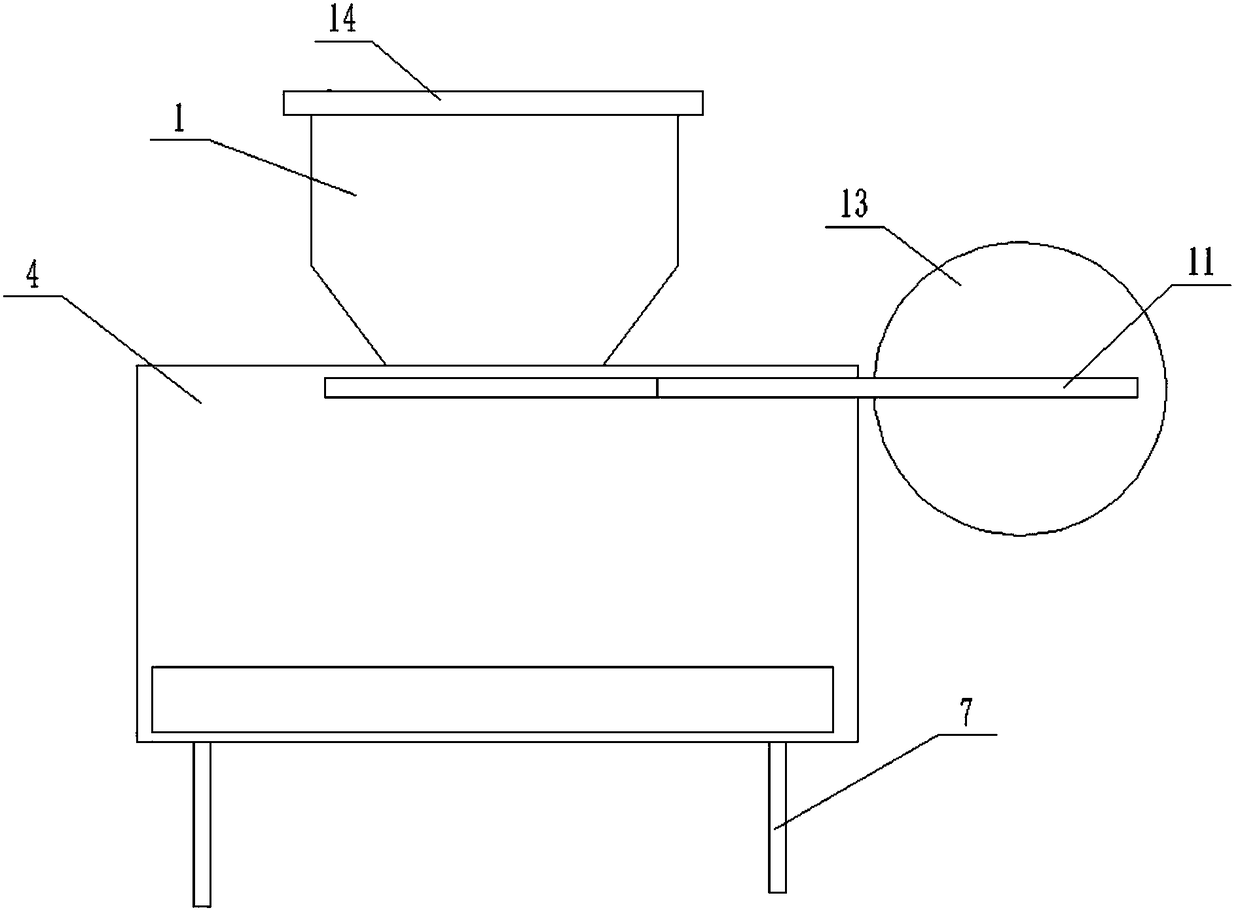

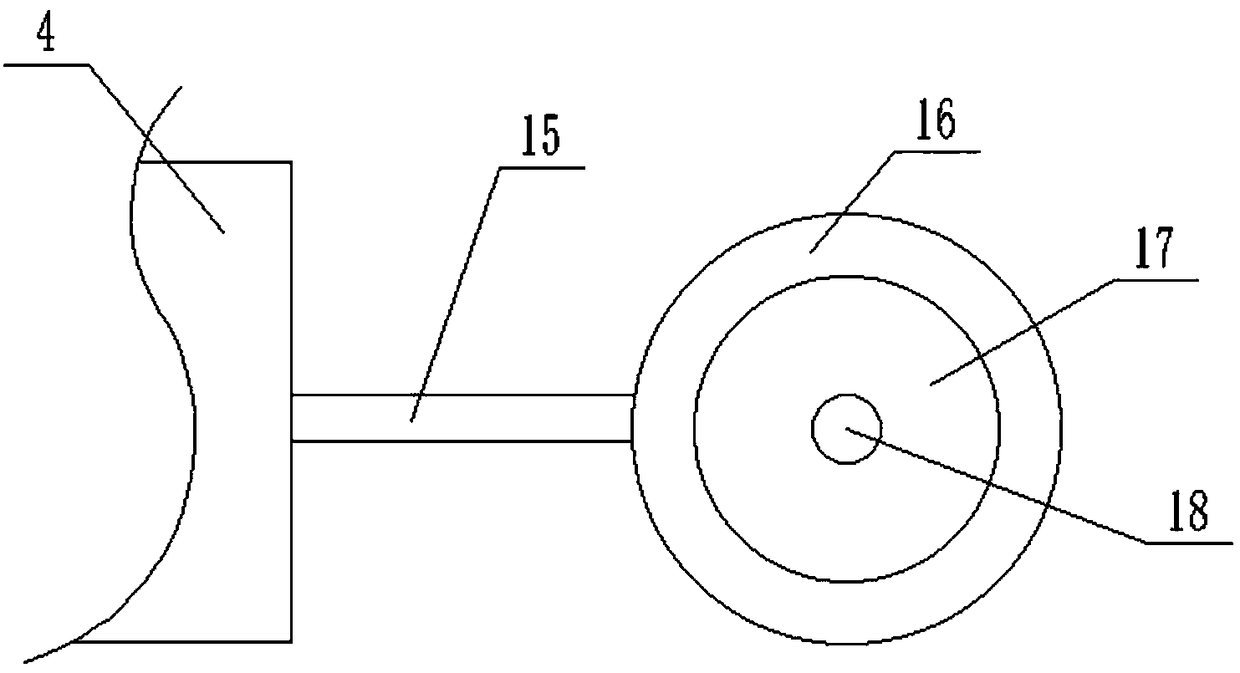

[0039] Combine below figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, and 15 illustrate this embodiment. The present invention relates to a screening device, more specifically, a screening device for road and bridge construction. Sand screening device, including feeding cylinder 1, pre-screening device 2, connecting rod 3, screening box 4, slide plate Ⅰ5, discharge barrel 6, bracket 7, screening device Ⅰ8, screening device Ⅱ9, screening device Ⅲ10, transmission rod 11, Sliding plate II 12, turntable 13, current limiting device 14, fixed rod 15, motor bracket 16, motor 17, rotating shaft 18, side baffle 19, not only can carry out multi-stage screening, discharge materials separately, but also can limit the flow of sand entering the device .

[0040] The pre-screening device 2 is made of a support plate 2-1 and a filter screen 2-2; the support plate 2-1 is conical, and the top of the support plate 2-1 is connected with a filter screen 2-2 by welding;

[0041] The screen...

specific Embodiment approach 2

[0051] Combine below figure 1 , 2 . There are more than one.

specific Embodiment approach 3

[0052] Combine below figure 1 , 2 . The hook groove 14-2-2 cooperates, and the U-shaped block 14-1-1 cooperates with the feeding cylinder 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com