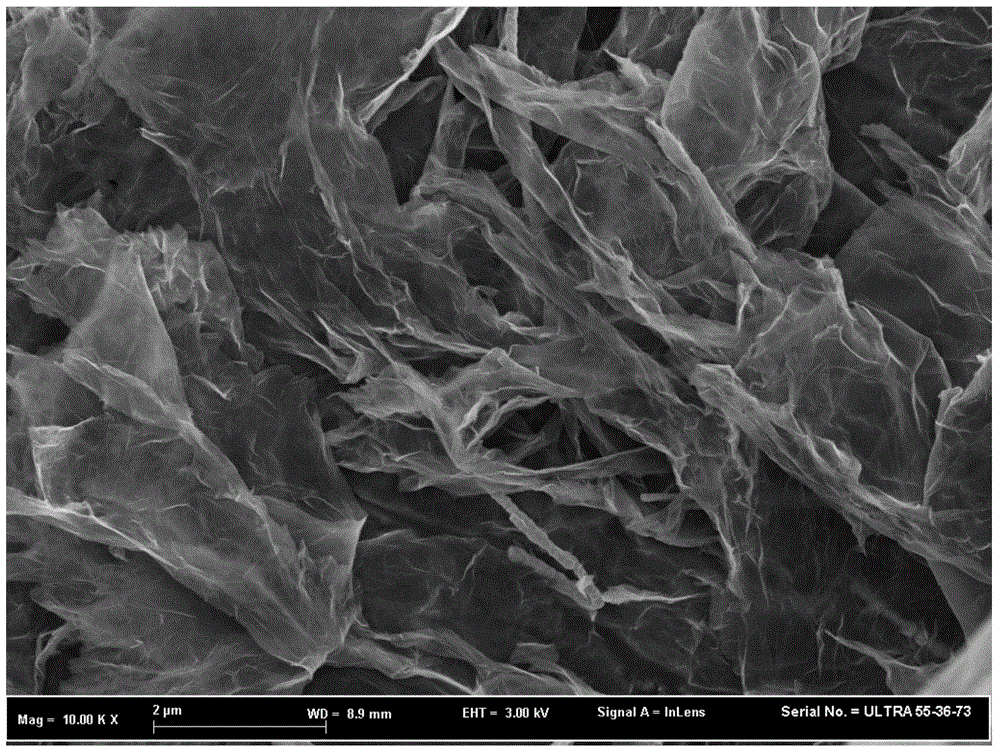

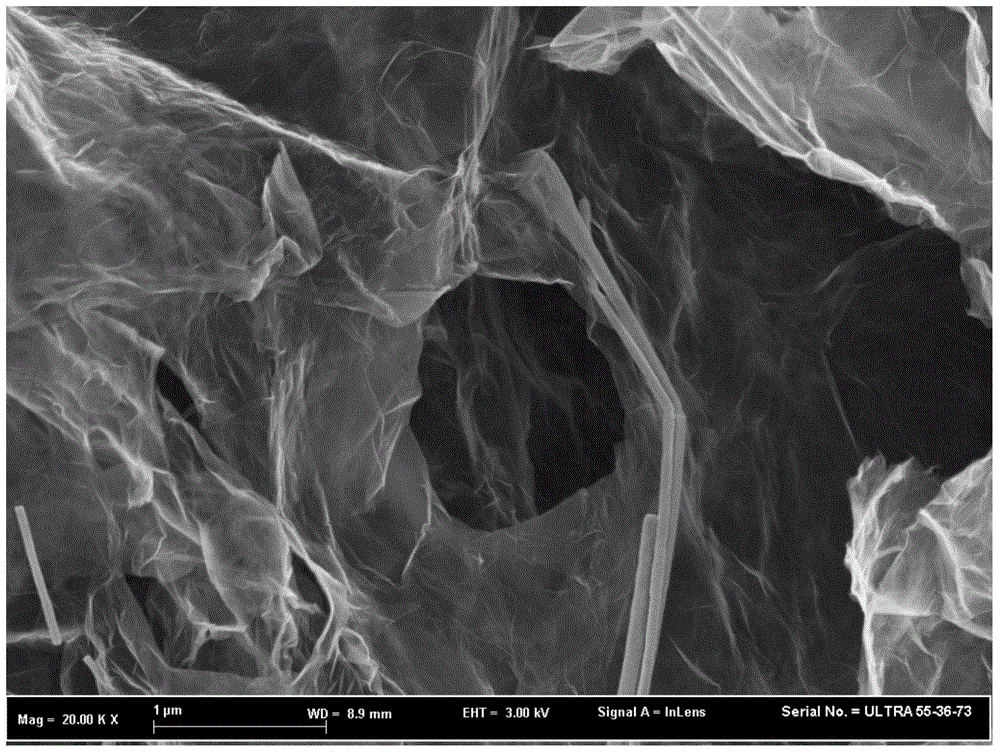

Method for preparing three-dimensional graphene-copper nanowire composite aerogel

A technology of composite airgel and copper nanowires, applied in chemical instruments and methods, colloid chemistry, colloid chemistry, etc., can solve problems such as poor compression performance, achieve high electrical conductivity, good mechanical stability, and simple and easy process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add the obtained graphite oxide into water, and sonicate for 4 hours to obtain an aqueous solution of graphene oxide, wherein the concentration of the graphene oxide solution is 8 mg / ml. Take 4 beakers (marked as A~D respectively) and add 18ml, 18ml, 16.25ml, 16.25ml of ethylene glycol respectively, so that the amounts in the 4 beakers are equal, and add them to the beakers in turn according to the ratio shown in Table 1 Copper nanowires, ascorbic acid, and graphene oxide solutions; each substance is added to form a uniformly dispersed mixed solution by mechanical stirring and ultrasonic treatment. Then transfer the mixed solution in the beaker to the polytetrafluoroethylene lining of the autoclave, put the reaction kettle in a blast drying oven at 160°C for 6 hours, and after the reaction is over, cool the reaction kettle to room temperature (25°C) ), to obtain a three-dimensional graphene-copper nanowire composite hydrogel. The columnar composite hydrogel obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com