Method for preparing nano metal oxide ceramic thin/thick film

A technology of oxide ceramics and nano-metals, applied in instruments, analytical materials, measuring devices, etc., can solve problems such as being unfavorable to obtain fine-grained and uniform nano-metal oxide films, achieve mutual contact and agglomeration inhibition, high efficiency, The effect of strong universality and generality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

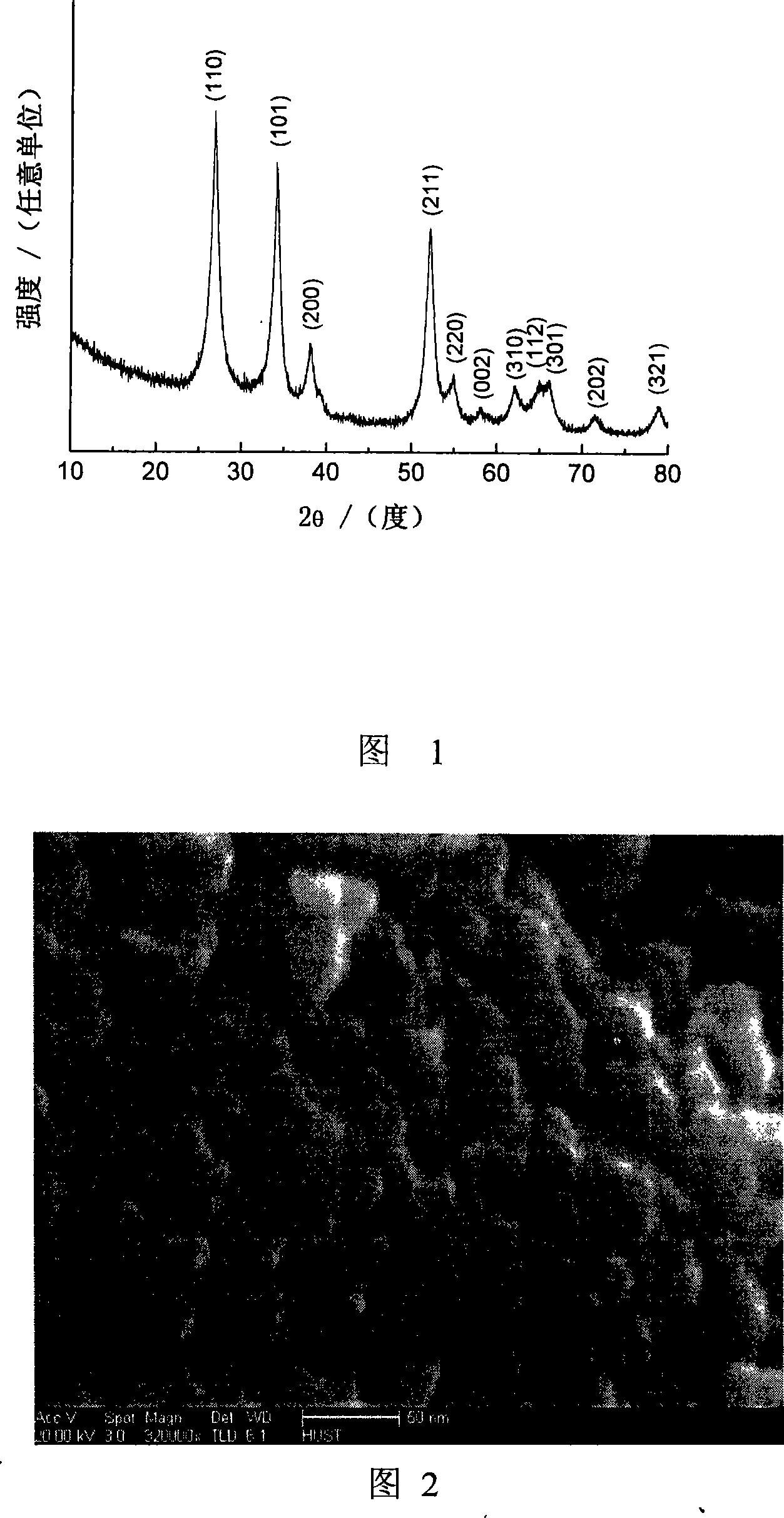

Examples

preparation example Construction

[0016] Conventional water-soluble metal inorganic salts (including one or more, such as doping) for preparing metal oxide ceramic film layers can be used as raw materials of the present invention. The organic monomer is acrylamide (AM); the crosslinking agent is N, N'-methylenebisacrylamide (MBAM); the initiator is ammonium persulfate (APS); every 100 ml of mixed solution contains metal inorganic salt 15-25 grams, 15-25 grams of organic monomer, the mass ratio of crosslinking agent to organic monomer is 0.01:1-0.1:1; the mass ratio of initiator to organic monomer is 0.02:1-0.05:1.

[0017] (2) Catalytic initiation to form a gel. In the above mixed solution, add the catalyst dropwise, and add 1.2 to 3 ml of N, N, N', N'-tetramethylethylenediamine (TEMED) per 100 ml of the mixed solution as a catalyst to initiate crosslinking of the organic monomer Copolymerize to form a three-dimensional network-like polymer, so that the mixed solution turns into a gel.

[0018] (3) Preparati...

Embodiment 1

[0024] (1) Preparation containing Sn 4+ , a mixed solution of organic monomers, crosslinking agents and initiators. 20 g tin tetrachloride pentahydrate SnCl 4 ·5H 2 O was dissolved in 100 ml of deionized water, 15 g of AM, 1.5 g of MBAM, and 0.6 g of APS were added, stirred evenly by magnetic force, and a stable mixed solution was obtained.

[0025] (2) Catalytic initiation to form a gel. In the above mixed solution, 1.5 milliliters of TEMED was added dropwise to initiate cross-linking and copolymerization of organic monomers to form a polymer with a three-dimensional network structure, turning the mixed solution into a gel.

[0026] (3) Preparation of slurry suitable for film coating. In order to facilitate film coating, 2 milliliters of a premix solution containing a water-soluble organic binder and a plasticizer was added to the above-mentioned gel, and its component distribution ratio was 18 grams of PVA: 6 milliliters of glycerin: 100 milliliters of deionized water. ...

Embodiment 2

[0031] (1) Preparation containing Sn 4+ , Sb 3+ , a mixed solution of organic monomers, crosslinking agents and initiators. 25 g tin tetrachloride pentahydrate SnCl 4 ·5H 2 O and 1.3 g antimony trichloride SbCl 3 Dissolve in 100 ml of deionized water, add 25 g of AM, 2.0 g of MBAM and 0.5 g of APS, and mix evenly with magnetic stirring to obtain a stable mixed solution.

[0032] (2) Catalytic initiation to form a gel. In the above mixed solution, 1.8 milliliters of TEMED was added dropwise to initiate cross-linking and copolymerization of organic monomers to form a polymer with a three-dimensional network structure, so that the mixed solution turned into a gel.

[0033] (3) Preparation of slurry suitable for film coating. In order to facilitate film coating, 2.5 milliliters of a premix solution containing a water-soluble organic binder and a plasticizer was added to the above-mentioned gel, and its component distribution ratio was 15 grams of PVA: 6 milliliters of glycer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com