A kind of copper-platinum superlattice alloy nanotube and preparation method thereof

An alloy nano and superlattice technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high cost, hinder the use of methanol fuel cell anode catalysts, and reduce catalytic performance, and achieve fast reaction and product. The effect of high conversion rate and simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

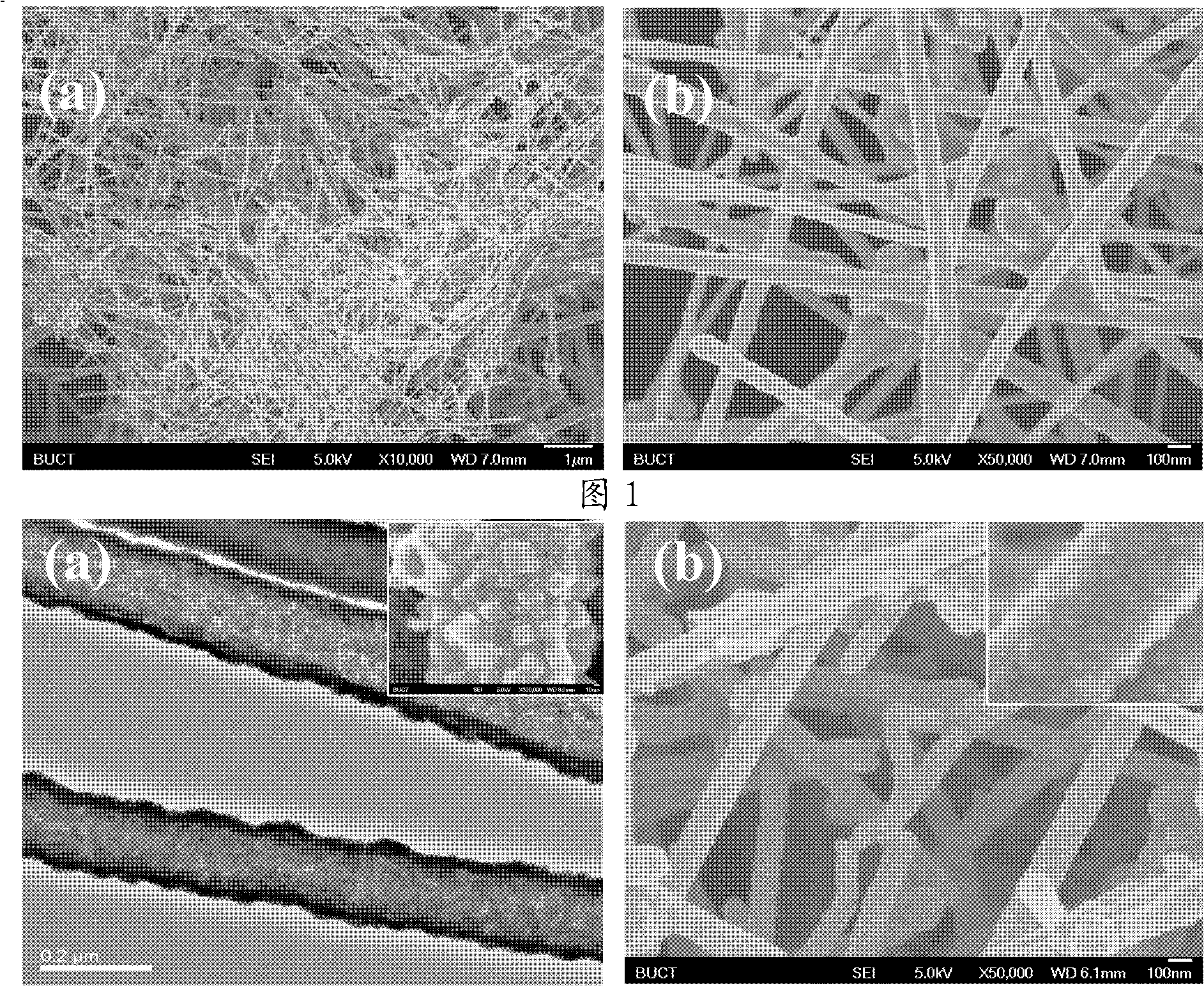

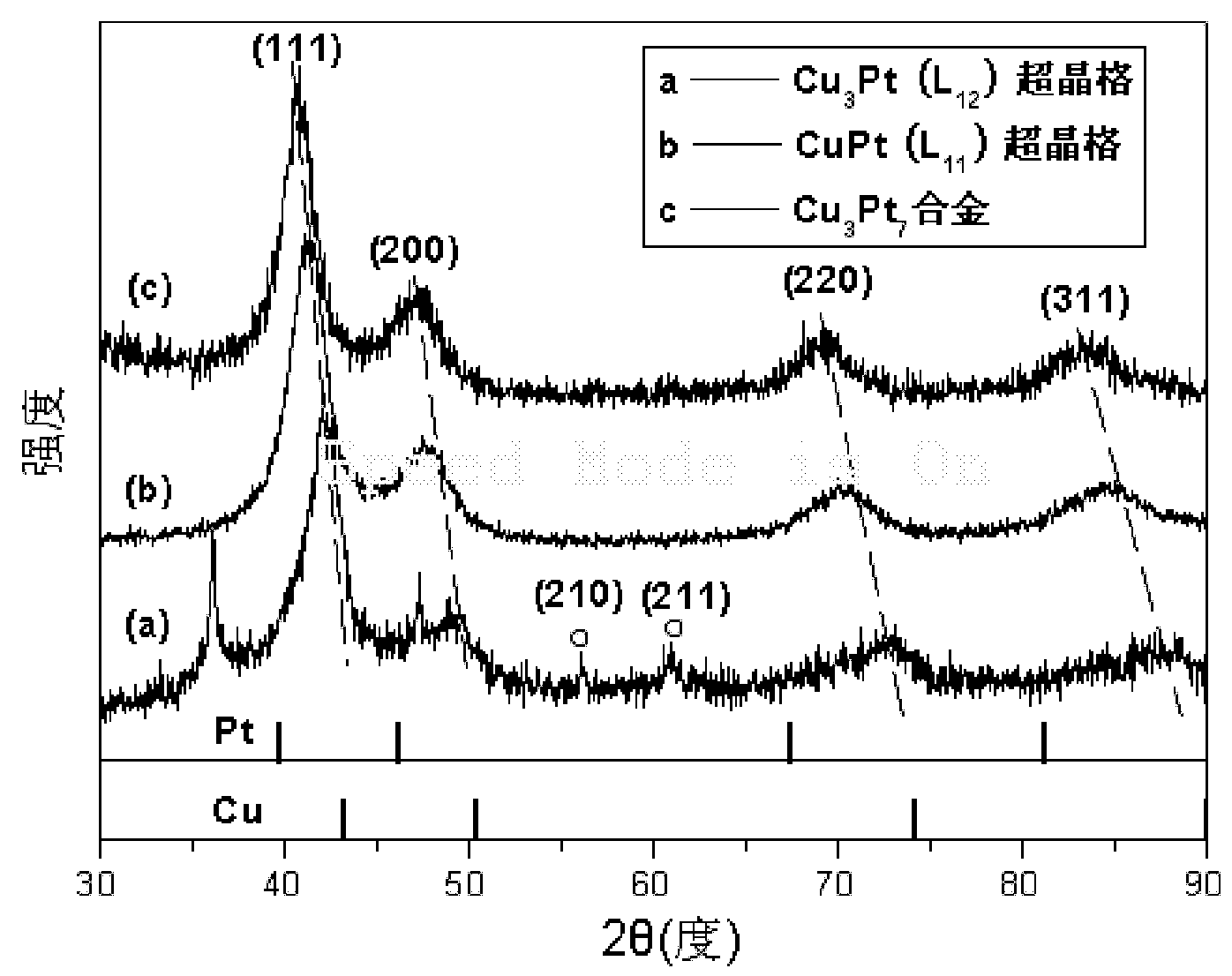

Embodiment 1

[0028] 1) Preparation of copper nanowires: First, add 120-180 g of sodium hydroxide and 4 mL of ethylenediamine into 300 mL of deionized water under mechanical stirring as a pH regulator and a shape control agent, respectively, and then add 15-30 mL of 0.1 mol / L copper nitrate solution as the precursor salt, then add 0.5-2mL hydrazine hydrate as the reducing agent, react in a water bath at 60°C-90°C for 30-60 minutes, and filter the product with deionized water that has been purged with nitrogen to remove oxygen Washed and dried in vacuum to obtain copper nanowires.

[0029] 2) Pretreatment of copper nanowires: first wash the copper nanowires with 0.1mol / L dilute hydrochloric acid to remove oxides and other basic impurities on the surface, then rinse with deionized water that has been deoxidized by nitrogen gas, and finally Put into a vacuum drying oven and dry at 60° C. for 12 hours.

[0030] 3) Preparation of copper nanowire slurry: Weigh 64 mg of pretreated copper nanowire...

Embodiment 2

[0033]1) Preparation of copper nanowires: First, add 120-180 g of sodium hydroxide and 4 mL of ethylenediamine to 300 mL of deionized water under mechanical stirring as a pH regulator and a shape control agent, and then add 15-30 mL of 0.1 mol / L copper nitrate solution as the precursor salt, then add 0.1-2mL hydrazine hydrate as the reducing agent, react in a water bath at 60-90°C for 30-60 minutes, and filter the product with deionized water that has been purged with nitrogen to remove oxygen Washed and dried in vacuum to obtain copper nanowires.

[0034] 2) Pretreatment of copper nanowires: first wash the copper nanowires with 0.1mL / L dilute hydrochloric acid to remove oxides and other basic impurities on the surface, then rinse with deionized water that has been deoxidized by nitrogen gas, and finally Put into a vacuum drying oven and dry at 60° C. for 12 hours.

[0035] 3) Preparation of copper nanowire slurry: Weigh 64 mg of pretreated copper nanowires, add 100 mL of dei...

Embodiment 3

[0038] 1) Preparation of copper nanowires: First, add 120-180 g of sodium hydroxide and 4 mL of ethylenediamine to 300 mL of deionized water under mechanical stirring as a pH regulator and a shape control agent, and then add 15-30 mL of 0.1 mol / L copper nitrate solution as the precursor salt, then add 0.1-2mL hydrazine hydrate as the reducing agent, react in a water bath at 60-90°C for 30-60 minutes, and filter the product with deionized water that has been purged with nitrogen to remove oxygen Washed and dried in vacuum to obtain copper nanowires.

[0039] 2) Pretreatment of copper nanowires: first wash the copper nanowires with 0.1mol / L dilute hydrochloric acid to remove oxides and other basic impurities on the surface, then rinse with deionized water that has been deoxidized by nitrogen gas, and finally Put into a vacuum drying oven and dry at 60° C. for 12 hours.

[0040] 3) Preparation of copper nanowire slurry: Weigh 64 mg of pretreated copper nanowires, add 100 mL of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com