Preparation method of antioxidant copper nanowires

A copper nanowire, anti-oxidation technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as limited applications, achieve low and constant contact resistance, prevent oxidation, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

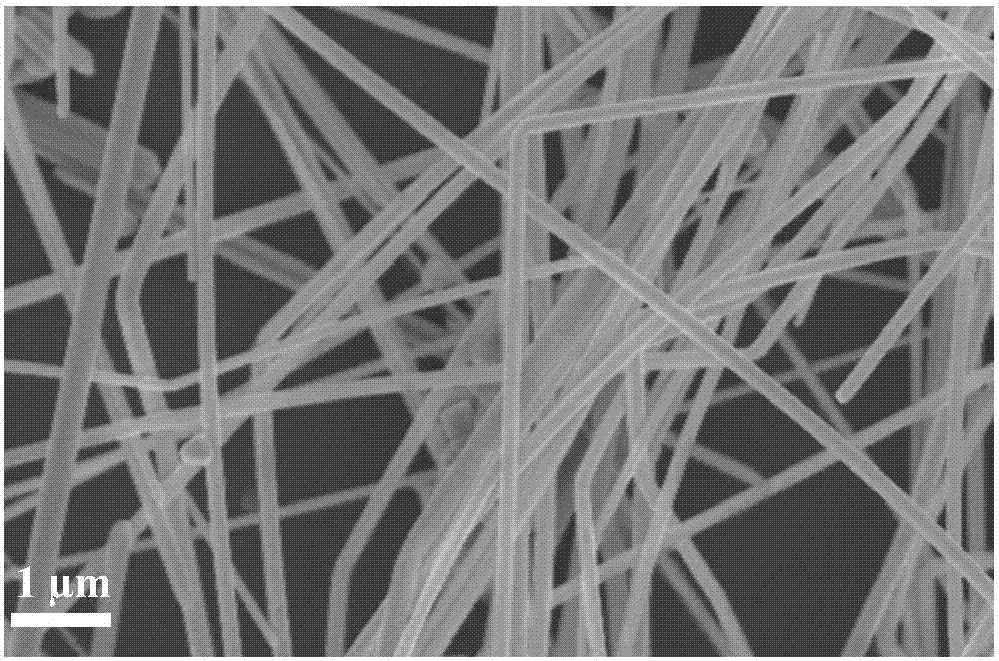

[0030] Step 1: Prepare copper nanowires with a diameter of 50-200nm: first weigh 1.7g CuCl 2 2H 2 O (~10mmol) and 1.93g glucose (~10mmol) were dissolved in 200mL deionized water and stirred evenly, then the mixed solution consisting of 20mL oleylamine, 0.2mL oleic acid and 35mL ethanol was slowly added to CuCl 2 2H 2 O and glucose mixed in aqueous solution, and then diluted to 1000mL. The above mixed solution was pre-reacted in an oil bath at 50°C for 12 hours. After the reaction, it was transferred to a hydrothermal reactor and reacted at 120°C for 6 hours. Finally, a red precipitate appeared at the bottom of the reactor, which was copper nanowires. Dissolve the copper nanowires in an ethanol solution (2.0 wt%) containing polyvinylpyrrolidone for ultrasonic dispersion until uniformly dispersed, centrifuge at 6000 rpm for 5 min, collect the precipitate and disperse the precipitate in absolute ethanol by ultrasonic, and then centrifuge for two to remove excess polyvinylpyrro...

Embodiment 2

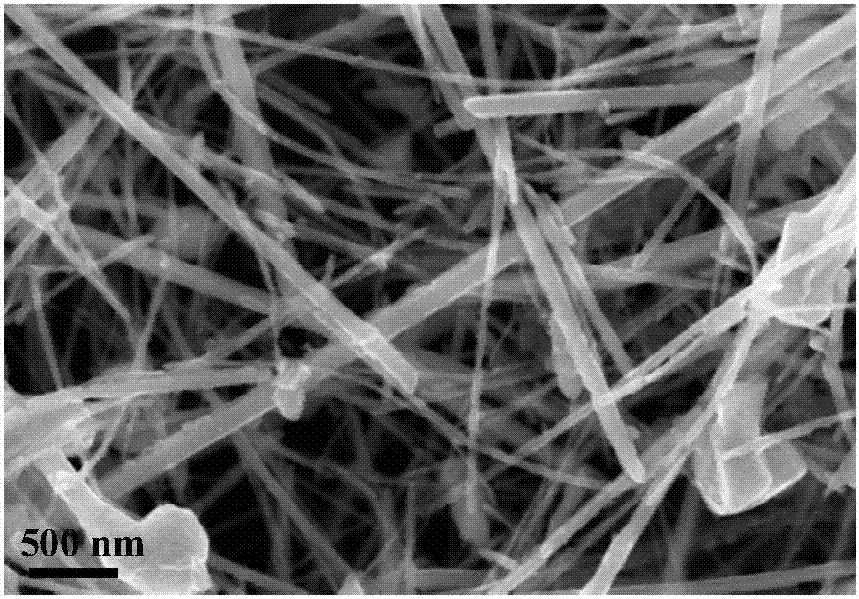

[0035] Preparation of copper nanowires with a diameter of 20nm: Weigh 0.5mmol of copper chloride and ultrasonically disperse it in 5mL of oleylamine, slowly raise the temperature to 70°C under the protective gas of nitrogen, add 0.424g of benzoin under the condition of stirring, and in a nitrogen atmosphere Heating to 120°C while stirring in the medium, stabilizing at this temperature for 30min, removing the nitrogen, heating to 185°C in a closed environment, and keeping at this temperature for 3h, the ultra-fine copper nanowires with a diameter of 20nm can be obtained. The copper nanowires were washed with hot ethanol and n-hexane several times to remove free organic matter, and finally the filter cake was dried in a drying oven for later use. Figure 5 It is a TEM picture of the prepared 20nm copper nanowire, which shows that the copper nanowire has good flexibility, with a diameter of 10-30nm and a length of about 10 μm.

[0036] Weigh 50 mg of copper nanowires, wash the or...

Embodiment 3

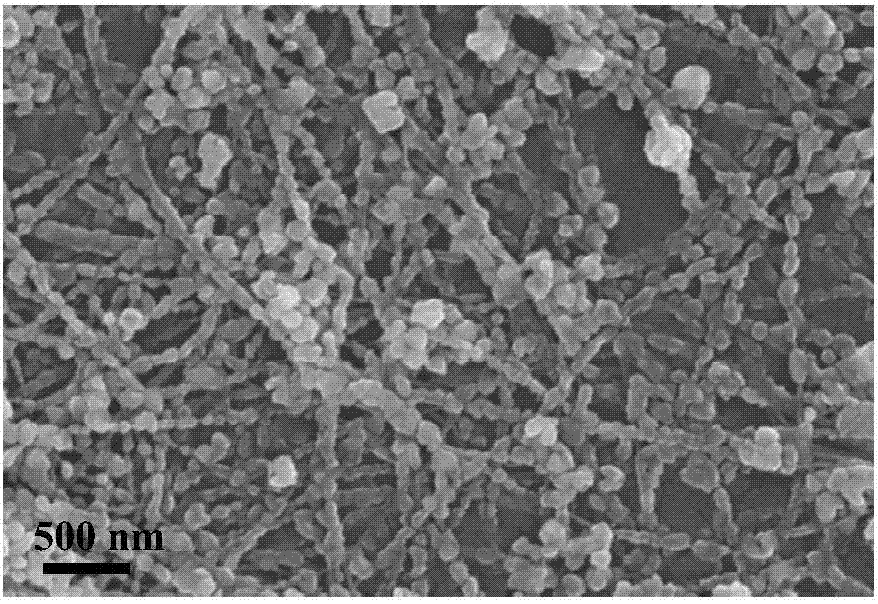

[0039] Weigh 200 mg of copper nanowires with a diameter of 50-200 nm, wash the organic matter on the surface with hot anhydrous ethanol for 10 minutes, then rinse with deionized water to remove the surface ethanol, and disperse the copper nanowires in 0.05M dilute sulfuric acid for 20 minutes Remove the oxide layer on the surface, then ultrasonically clean it with ultrapure water for 10 minutes, and dry it for later use. Place the copper nanowires in a high-temperature and high-pressure container containing 500 mg of magnesium formate and 10 mL of ethylene glycol solution for ultrasonication for 5 minutes, then raise the temperature from room temperature to 150°C within 30 minutes, then keep it at 150°C for 15 hours, cool naturally, and use ultrapure water After washing with absolute ethanol for several times, formate-modified anti-oxidation copper nanowires can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com