Ligand-free atom transfer radical polymerization method under effect of metal elementary substances

A metal element, atom transfer technology, used in the field of atom transfer radical polymerization and ligand-free atom transfer radical polymerization, can solve the problems of high toxicity and high price, achieve good control, promote balanced movement, and reduce damage degree and effect of response cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] After purification of methyl methacrylate monomer, ethyl 2-bromoisobutyrate halogenated hydrocarbon and micron iron powder, the polymerization reaction components are prepared, methyl methacrylate, ethyl 2-bromoisobutyrate, bromine The molar ratio of ferrous oxide (low-valence state transition metal catalyst) to metal iron powder is 200:1:1:0.5. The preparation process is as follows: weigh 0.061 grams of ferrous bromide and 0.0079 grams of iron powder in the glove box and put them into an eggplant-shaped bottle, add 6 milliliters of methyl methacrylate monomer into the eggplant-shaped bottle, and stir magnetically for 20 minutes. , and then added 37.7 microliters of ethyl 2-bromoisobutyrate, and continued to stir for 2 minutes to obtain a pre-reaction mixture.

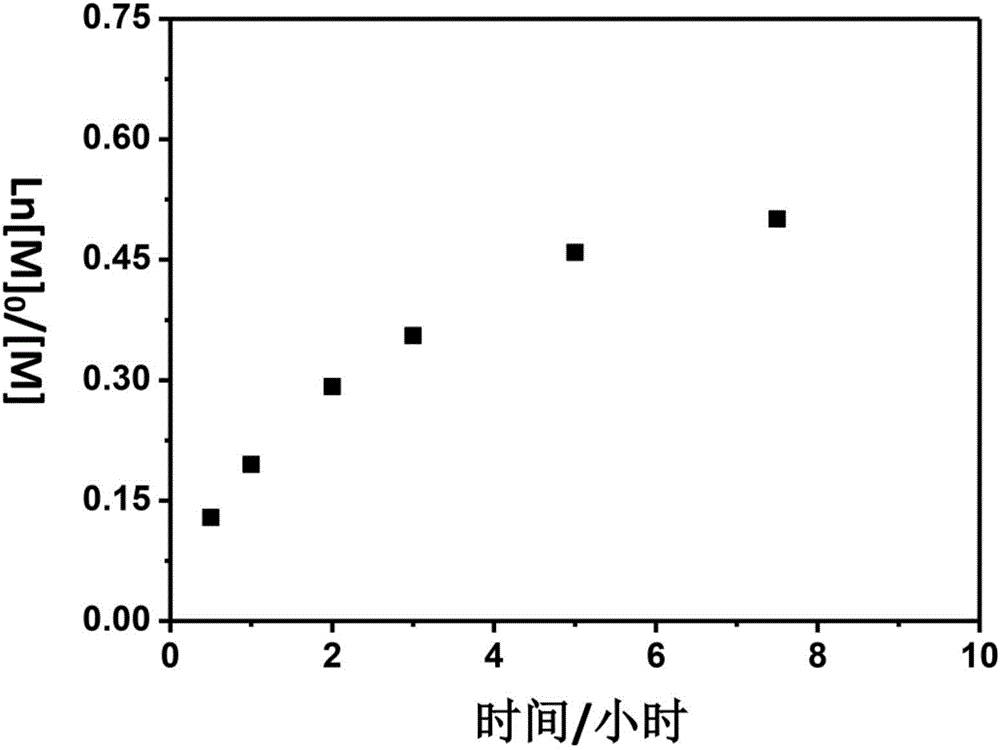

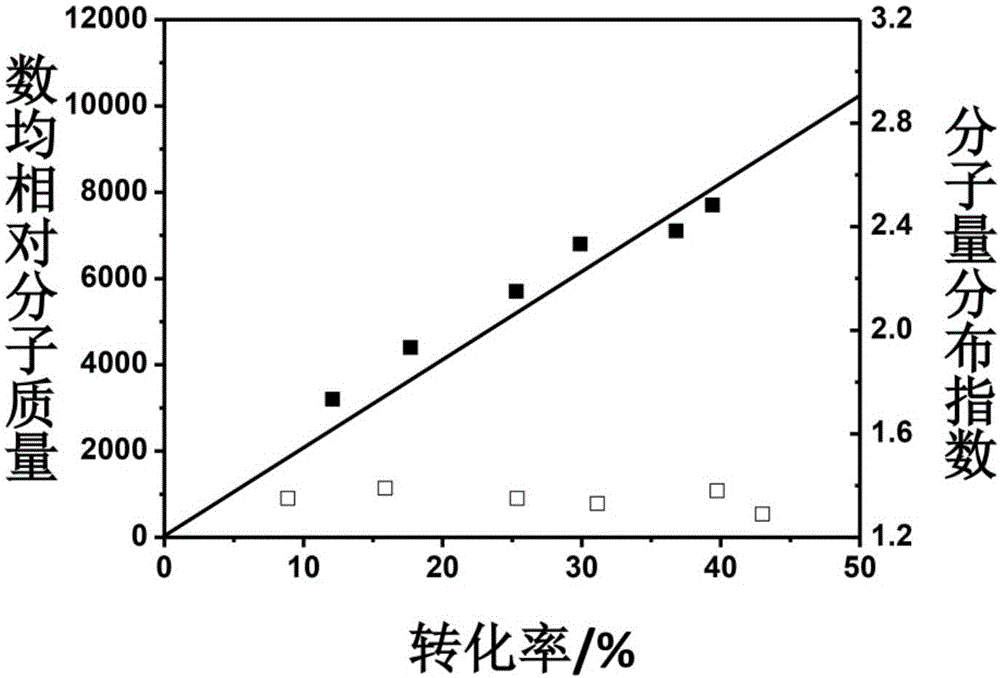

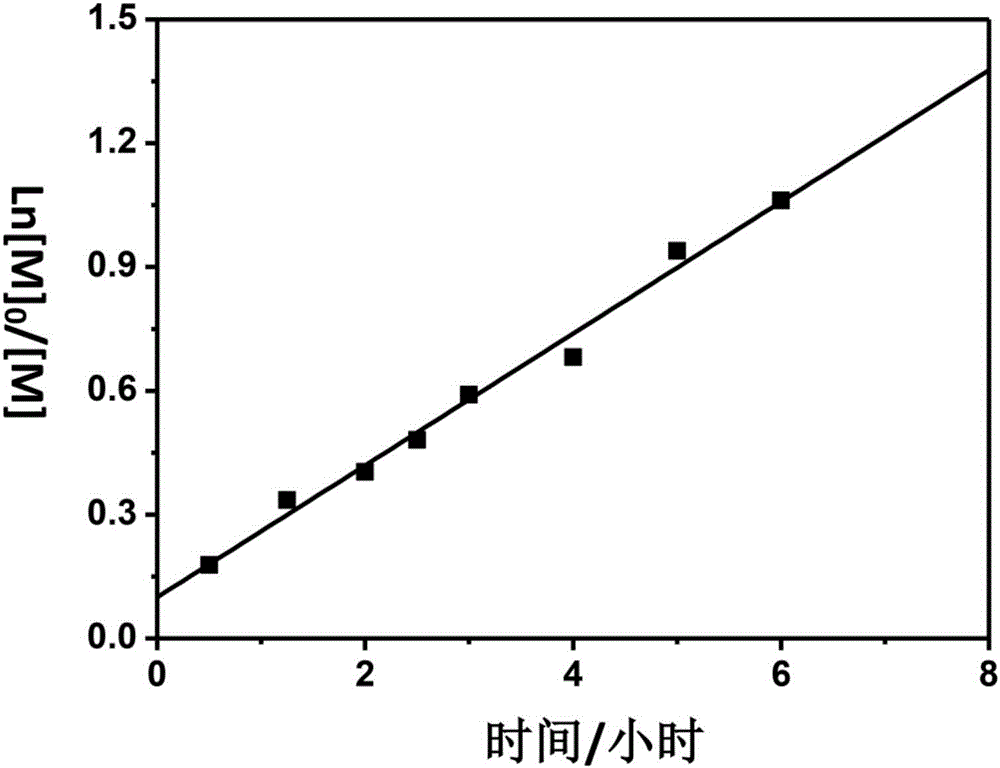

[0049] Transfer the pre-reaction mixture in the eggplant-shaped bottle to the heating device, and control the reaction temperature to 60°C; after the polymerization reaction reaches the predetermined reaction ti...

Embodiment 2

[0051] After purification of methyl methacrylate monomer, ethyl 2-bromophenylacetate, halogenated hydrocarbons, and silver nanowires, the polymerization reaction components were prepared, methyl methacrylate, ethyl 2-bromophenylacetate, bromine The molar ratio of ferrous oxide (low-valence state transition metal catalyst) to nano-silver wire is 200:1:1:0.25. The preparation process is as follows: Weigh 0.061 g of ferrous bromide and 0.0075 g of nano-silver wire into an eggplant-shaped bottle in a glove box, add 6 ml of methyl methacrylate monomer into the eggplant-shaped bottle, and stir magnetically for 20 minutes Then, 49.5 microliters of ethyl 2-bromophenylacetate was added, and the stirring was continued for 2 minutes to obtain a pre-reaction mixture.

[0052] Transfer the pre-reaction mixture in the eggplant-shaped bottle to the heating device, and control the reaction temperature to 60°C; after the polymerization reaction reaches the predetermined reaction time interval,...

Embodiment 3

[0055] After purification of methyl methacrylate monomer, ethyl 2-bromophenylacetate halogenated hydrocarbons and silver nanowires, the polymerization reaction components were prepared, methyl methacrylate, ethyl 2-bromophenylacetate, bromine The molar ratio of ferrous oxide (low-valence state transition metal catalyst) to nano-silver wire is 200:1:1:0.1. The preparation process is as follows: Weigh 0.061 grams of ferric bromide and 0.003 grams of nano-silver wires into an eggplant-shaped bottle in a glove box, add 6 milliliters of methyl methacrylate monomer into the eggplant-shaped bottle, and stir magnetically for 20 minutes. , and then added 49.5 microliters of ethyl 2-bromophenylacetate, and continued to stir for 2 minutes to obtain a pre-reaction mixture.

[0056] Transfer the pre-reaction mixture in the eggplant-shaped bottle to the heating device, and control the reaction temperature to 60°C. After the polymerization reaction reaches the predetermined reaction time int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com