Liquid phase method for synthesizing one-dimensional super long Nano line of metal copper

A liquid phase synthesis, copper nanowire technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of harsh implementation conditions, complex processes, high cost, and achieve cheap raw materials, good repeatability, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

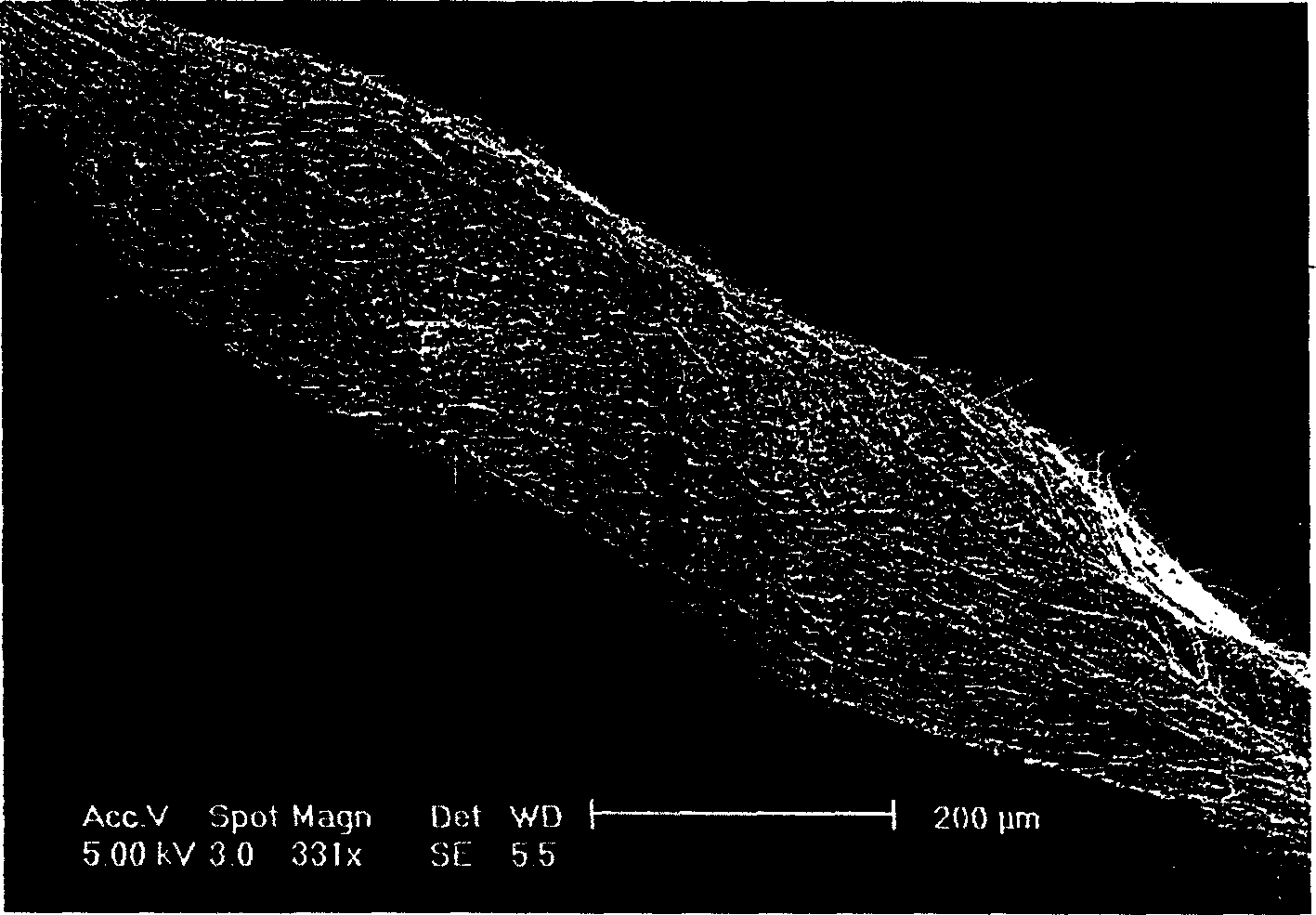

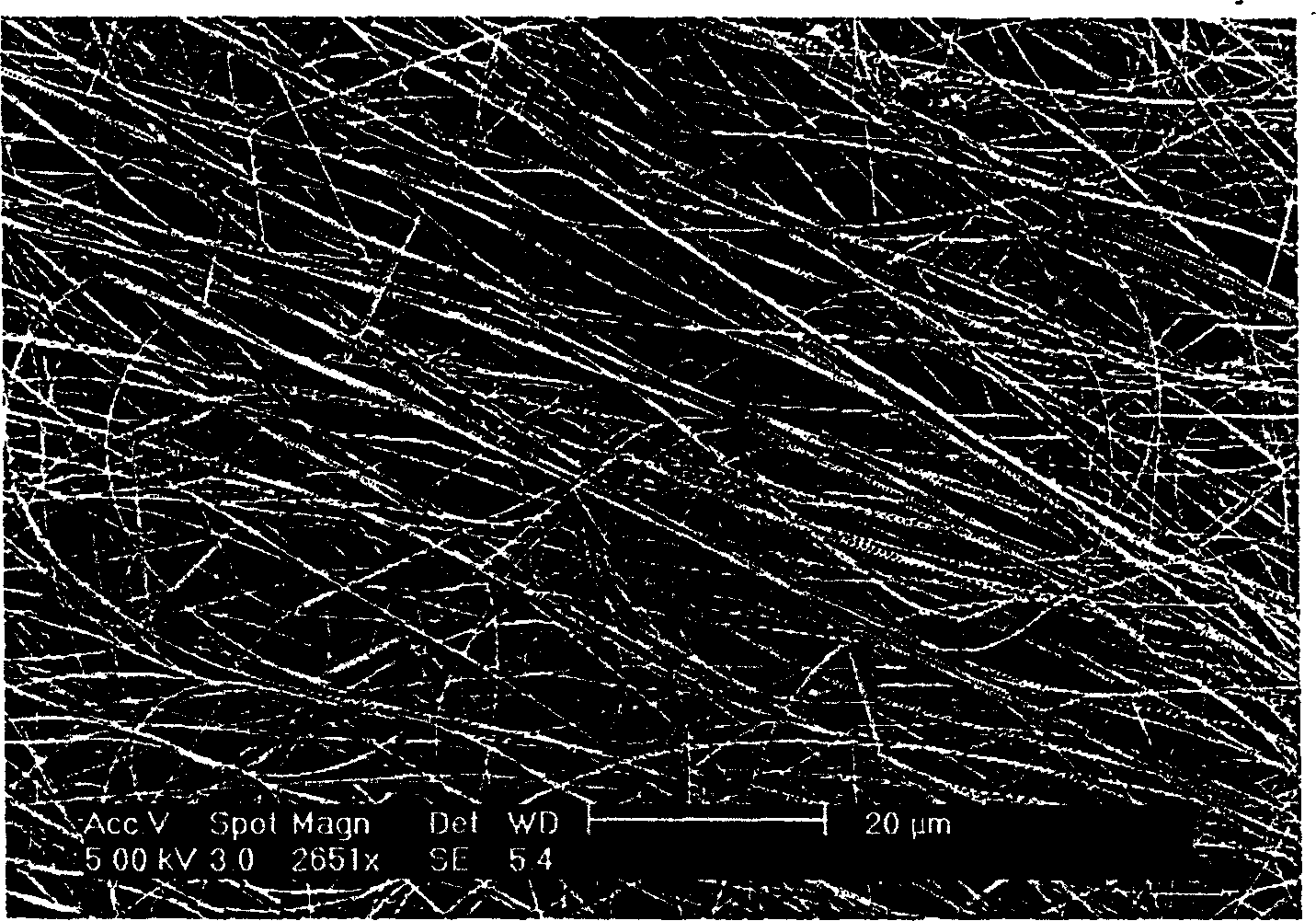

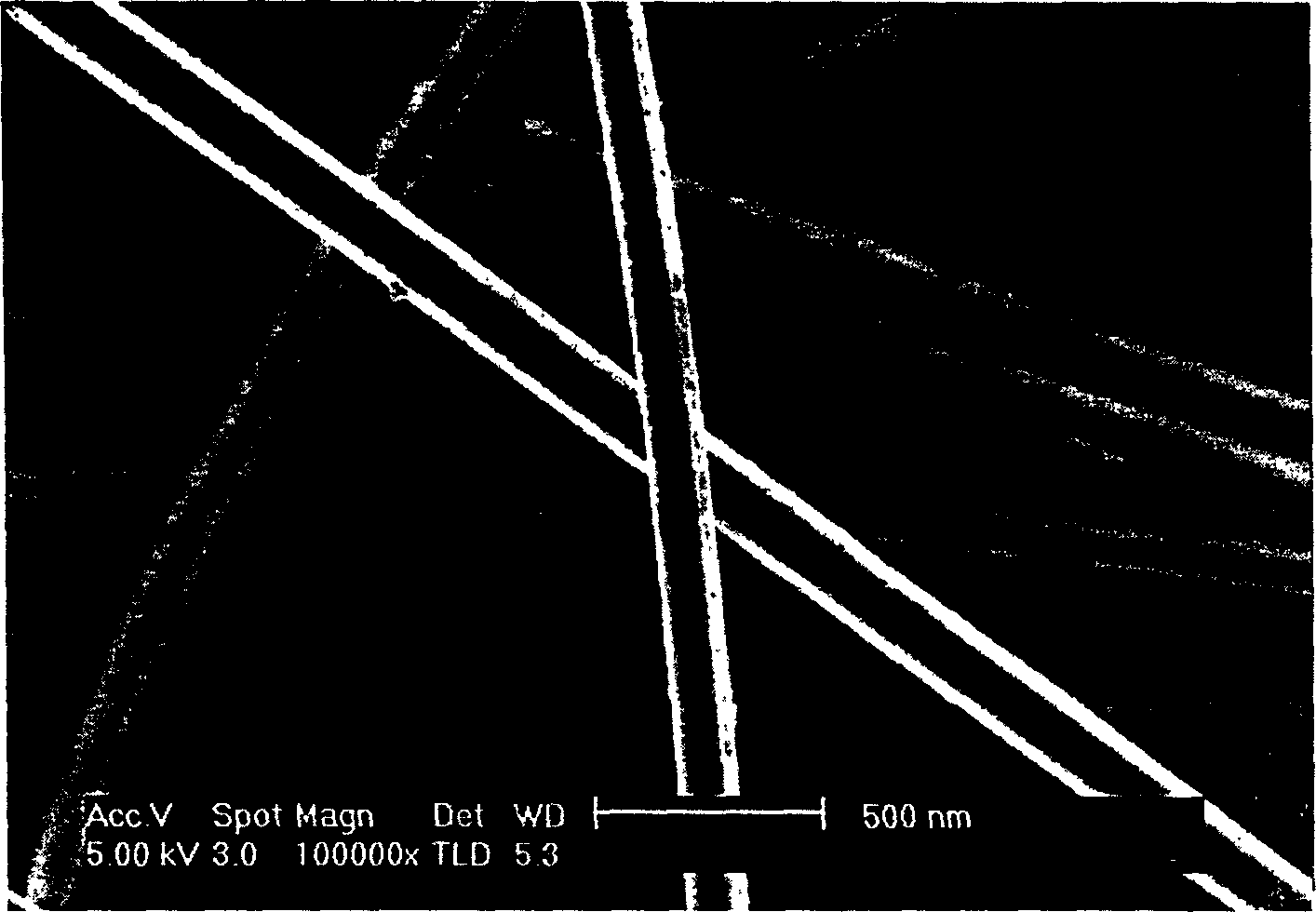

Embodiment 1

[0024] Embodiment 1: Weigh the CuCl of 0.001mol 2 2H 2 O in a stirred reactor, add 100ml distilled water, stir to dissolve, then add 0.001mol octadecylamine (C 18 h 37 NH 2 ), stirred well until a uniform blue emulsion was formed without undissolved octadecylamine. Transfer the obtained liquid into a stainless steel pressure melting bomb with a filling degree of 85%, seal it tightly, raise the temperature to 120°C and keep it for 72 hours, then naturally cool to room temperature, collect the obtained solid product after centrifugation, and use absolute ethanol, n-hexane And washed with deionized water for more than three times, at room temperature, 10 -3 Vacuum drying under atmospheric pressure for 1 hour, and vacuum drying, the product has an average diameter of 50 nm and a length of up to 10 nm. -3 meters of copper nanowires.

Embodiment 2

[0025] Embodiment 2: Weigh the CuCl of 0.001mol 2 2H 2 O in a stirred reactor, add 75ml distilled water, stir to dissolve, then add 0.002mol octadecylamine (C 18 h 37 NH 2 ), stirred well until a uniform blue emulsion was formed without undissolved octadecylamine. Transfer the obtained liquid into a stainless steel pressure melting bomb with a filling degree of 80%, seal it tightly, raise the temperature to 160°C and keep it for 50 hours, then naturally cool to room temperature, collect the obtained product after centrifugation, and use absolute ethanol, n-hexane and Wash with deionized water more than three times, at room temperature, 10 -3 Vacuum drying under atmospheric pressure for 4 hours, vacuum drying, the average diameter of the product is 150nm, the length can reach 10 -2 meters of copper nanowires.

Embodiment 3

[0026] Embodiment 3: Weigh the CuCl of 0.002mol 2 2H 2 O in a stirred reactor, add 75ml distilled water, stir to dissolve, then add 0.004mol octadecylamine (C 18 h 37 NH 2), stirred well until a uniform blue emulsion was formed without undissolved octadecylamine. Transfer the obtained liquid into a stainless steel pressure melting bomb with a filling degree of 65%, seal it tightly, raise the temperature to 200°C and keep it for 20 hours, then naturally cool to room temperature, collect the obtained product after centrifugation, and use absolute ethanol, n-hexane and Wash with deionized water more than three times, at room temperature, 10 -3 Vacuum drying under atmospheric pressure for 3 hours, and vacuum drying, the product has an average diameter of 10 nm and a length of up to 10 nm. -2 meters of copper nanowires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com