Preparation method for copper/silver nanowires of core-shell structures

A technology of copper nanowires and nanowires, which is applied in the field of preparation of copper/silver core-shell nanowires, can solve the problems affecting the performance of metal nanowires, looseness, loose silver layer structure, etc., and achieve low preparation and preservation costs, Good stability and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

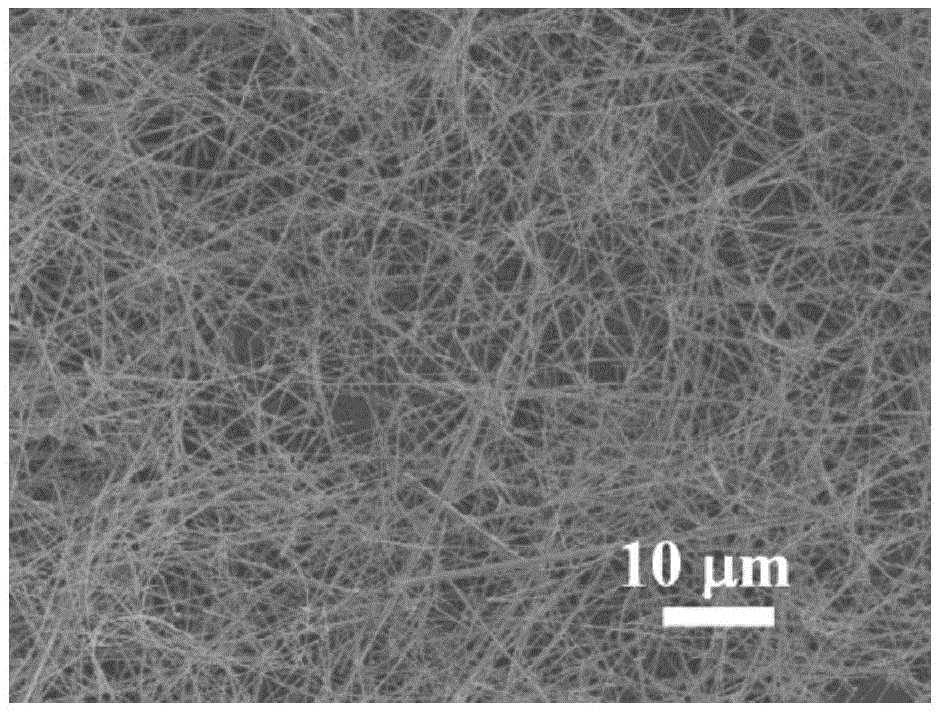

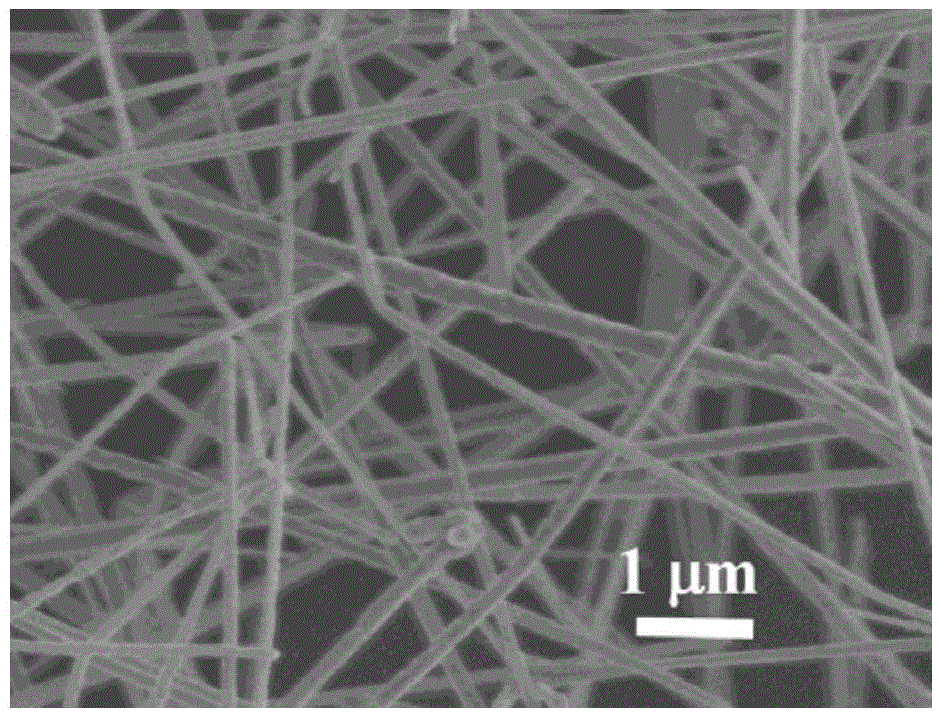

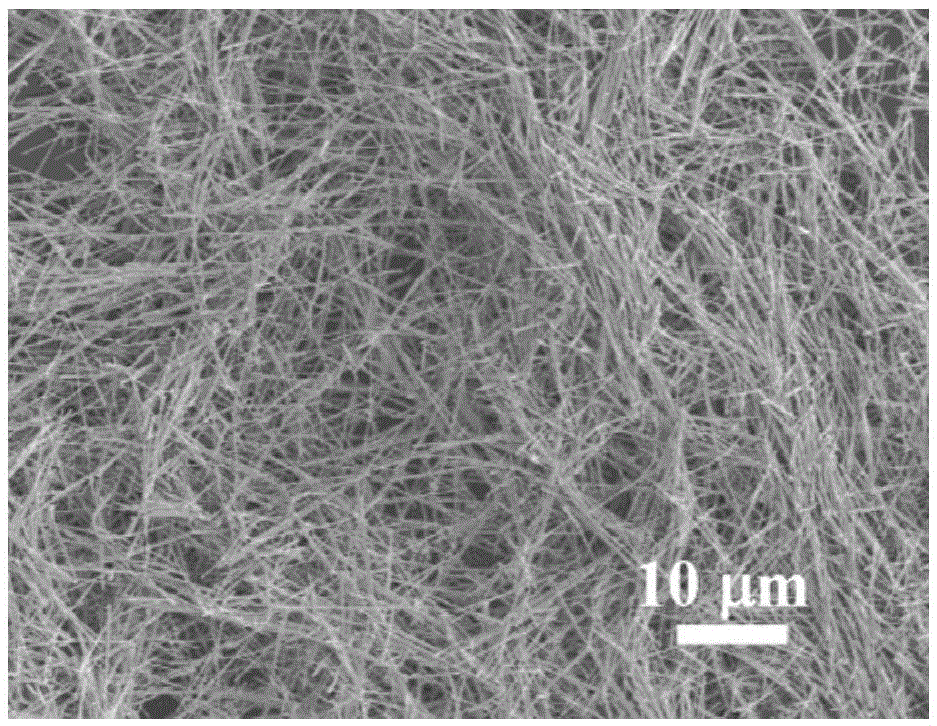

Image

Examples

Embodiment 1

[0056] (1) equipped with sodium hydroxide (NaOH) and copper nitrate (CuNO 3 ) aqueous solution, the concentrations are respectively 15mol / L and 0.1mol / L;

[0057] (2) The copper nitrate solution prepared in step (1) is added to the sodium hydroxide solution placed in the single-necked flask, wherein the volume ratio of the copper nitrate solution to the sodium hydroxide solution is 1 / 20, and the two are 31.5ml in total ; Then add 415 μL of ethylenediamine (EDA), then place the flask in an oil bath and stir thoroughly, and heat to 70°C;

[0058] (3) add 85ωt% hydrazine hydrate (N 2 h 4 .H 2 0) 18 μL of solution, fully stirred for 2 to 3 minutes, and left to stand for 35 minutes after insulated to form a bright Cu nanowire film floating on the upper layer of the solution;

[0059] (4) collect the product Cu nanowires obtained in step (3), first wash and shake with deionized water, centrifuge at 6000-8000 rpm for 10 minutes, discard the supernatant; wash and shake with deioni...

Embodiment 2

[0070] (1) equipped with sodium hydroxide (NaOH) and copper nitrate (CuNO 3 ) aqueous solution, the concentrations are respectively 15mol / L and 0.1mol / L;

[0071] (2) The prepared copper nitrate solution is added to the sodium hydroxide solution placed in the single-necked flask, wherein the volume ratio of the copper nitrate solution to the sodium hydroxide solution is 1 / 20, and the two are 31.5ml in total; Diamine (EDA) 415 μL, then, place the flask in an oil bath, stir well, and heat to 70°C;

[0072] (3) add 85ωt% hydrazine hydrate (N to the mixed solution that step (2) obtains 2 h 4 .H 2 0) 18 μL of solution, fully stirred for 2 to 3 minutes, and left to stand for 35 minutes after insulated to form a bright Cu nanowire film floating on the upper layer of the solution;

[0073] (4) Collect the Cu nanowires obtained in step (3), first wash and oscillate with deionized water, centrifuge at 6000 to 8000 rpm for 10 min, discard the supernatant; wash and oscillate again wit...

Embodiment 3

[0082] (1) equipped with sodium hydroxide (NaOH) and copper nitrate (CuNO 3 ) aqueous solution, the concentrations are respectively 15mol / L and 0.1mol / L;

[0083] (2) The prepared copper nitrate solution is added to the sodium hydroxide solution placed in the single-necked flask, wherein the volume ratio of the copper nitrate solution to the sodium hydroxide solution is 1 / 20, and the two are 31.5ml in total; Diamine (EDA) 415 μL, then, place the flask in an oil bath, stir well, and heat to 65°C;

[0084] (3) add 85ωt% hydrazine hydrate (N 2 h 4 .H 2 0) 18 μL of solution, fully stirred for 2 to 3 minutes, and left to stand for 1 hour after insulated to form a bright Cu nanowire film floating on the upper layer of the solution;

[0085] (4) Collect the Cu nanowires obtained in step (3), first wash and oscillate with deionized water, centrifuge at 6000 to 8000 rpm for 10 min, discard the supernatant; wash and oscillate again with deionized water and centrifuge 3 times;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com