Method for preparing Ag/AgCl/BiMg2VO6 composite photocatalyst

A catalyst and composite light technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low photocatalytic activity, inhibiting the effective separation of carriers, limiting the range of light absorption, etc. Achieve the effects of low reaction temperature, good photocatalytic activity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

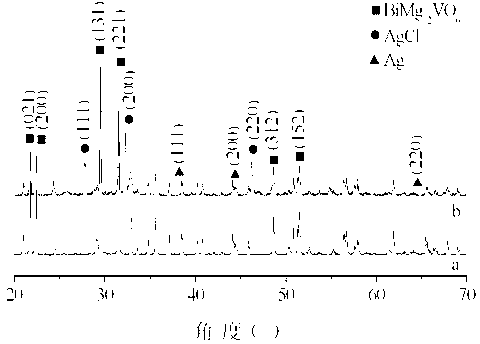

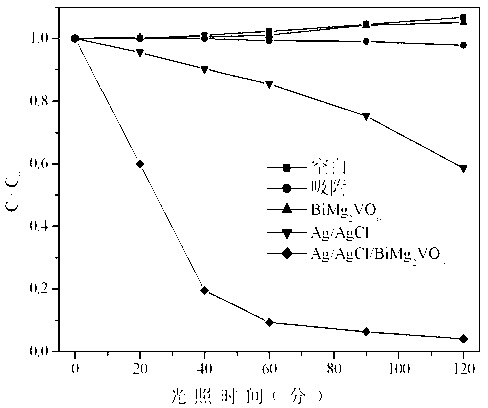

Image

Examples

Embodiment 1

[0028] Ag / AgCl / BiMg with Visible Light Photocatalytic Activity 2 VO 6 The preparation method of composite photocatalyst, it comprises the following steps:

[0029] 1) Add 0.072 mol (i.e. 15.1301 g) of citric acid to 30 mL of deionized water, then add 0.018 mol (i.e. 8.7318 g) of bismuth nitrate pentahydrate, heat and stir at 80 °C to obtain milky white solution A; take 0.048 mol (i.e. 14.0275 g, about 14 g) chelating agent EDTA was added to 30 mL of ammonia water, stirred and dissolved, then added to the above solution A, and heated and stirred at 80 °C until a colorless and transparent bismuth acid solution was formed;

[0030] Take 0.036 mol (9.2308 g) of magnesium nitrate hexahydrate and 0.018 mol (2.1058 g) of ammonium metavanadate, and add them to 30 mL of deionized water respectively to obtain magnesium nitrate hexahydrate solution and ammonium metavanadate solution, and then add the above In bismuth acid solution, heat and stir continuously at 80 °C for 3-5 h to obtai...

Embodiment 2

[0040] Ag / AgCl / BiMg with Visible Light Photocatalytic Activity 2 VO 6 The preparation method of composite photocatalyst, it comprises the following steps:

[0041] 1) Preparation of BiMg 2 VO 6 The process of base material is completely consistent with the step 1) of embodiment 1;

[0042] 2) Take 0.5 g BiMg 2 VO 6 The matrix material was added to 30 mL deionized water and ultrasonicated for 10 min to obtain BiMg 2 VO 6 suspension;

[0043] Ag ion / BiMg in silver nitrate solution 2 VO 6 The proportion of matrix material is 1 mmol / g, in the above BiMg 2 VO 6 Slowly add 5 mL of silver nitrate solution with a concentration of 0.1 mol / L dropwise into the suspension, sonicate for 10 min, and stir for 20 min at room temperature in the dark;

[0044] 3) According to the molar ratio of Ag ions in the silver nitrate solution to H ions in the hydrochloric acid solution was 1:1, slowly add 5 mL of hydrochloric acid solution with a concentration of 0.1 mol / L, sonicate for 10 mi...

Embodiment 3

[0048] Ag / AgCl / BiMg with Visible Light Photocatalytic Activity 2 VO 6 The preparation method of composite photocatalyst, it comprises the following steps:

[0049] 1) Preparation of BiMg 2 VO 6 The process of base material is completely consistent with the step 1) of embodiment 1;

[0050] 2) Take 0.5 gBiMg 2 VO 6 The matrix material was added to 30 mL deionized water and ultrasonicated for 10 min to obtain BiMg 2 VO 6 suspension;

[0051] Ag ion / BiMg in silver nitrate solution 2 VO 6 The proportion of matrix material is 3 mmol / g, in the above BiMg 2 VO 6 Slowly add 15 mL of silver nitrate solution with a concentration of 0.1 mol / L dropwise into the suspension, sonicate for 10 min, and stir for 20 min at room temperature in the dark;

[0052] 3) According to the molar ratio of Ag ions in the silver nitrate solution to H ions in the hydrochloric acid solution is 1:1, slowly add 15 mL of hydrochloric acid solution with a concentration of 0.1 mol / L, sonicate for 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com