Magnetic bentonite loaded spherical BiOBr, preparation method and application thereof

A bentonite and magnetic technology, applied in the field of visible light catalyst preparation, can solve the problems of reducing the utilization efficiency of visible light, hindering photocatalytic efficiency, unfavorable industrial application, etc., and achieve the effect of repeated use of photocatalytic activity, enhanced adsorption and enrichment ability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

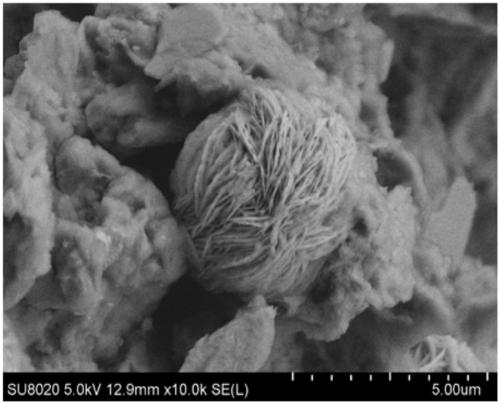

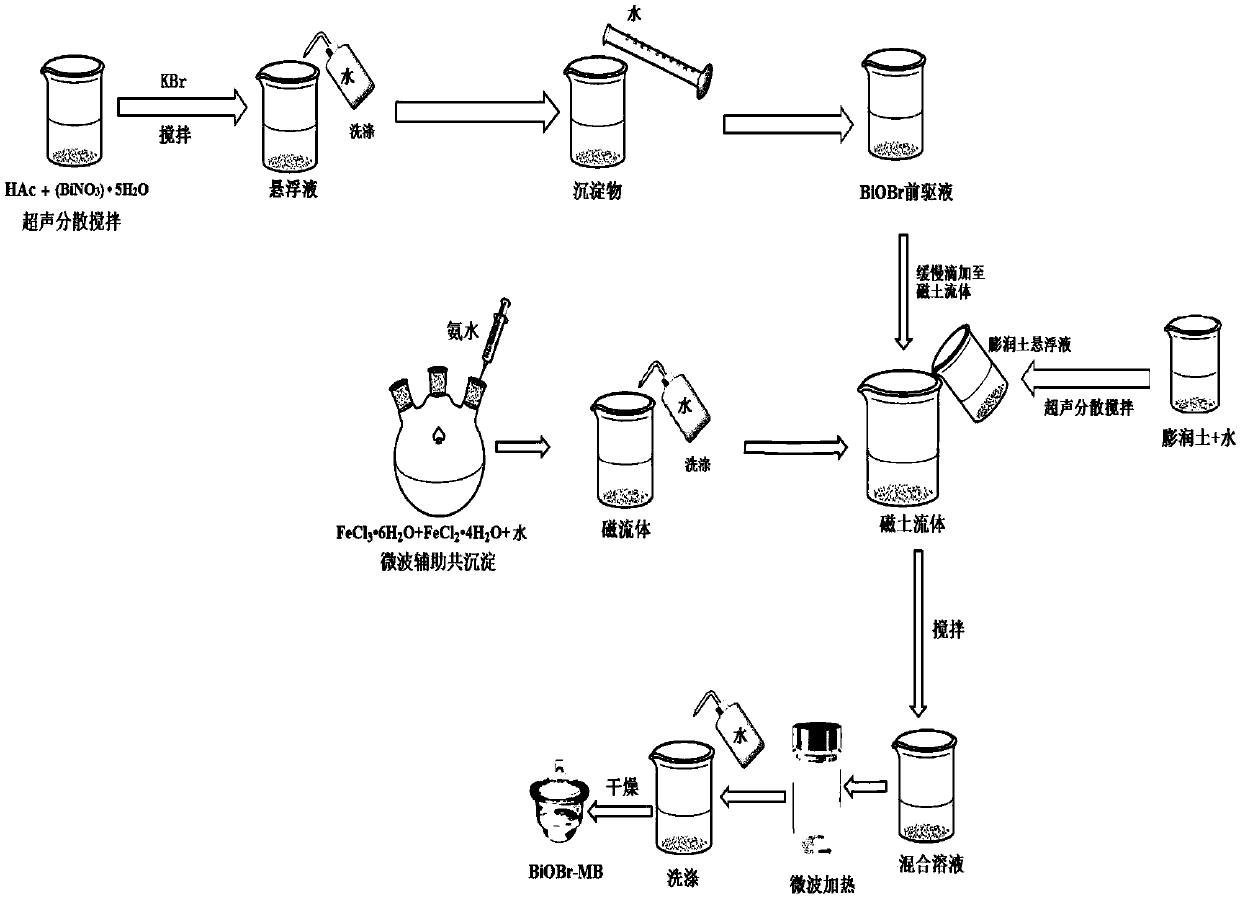

[0056] Preparation of Spherical BiOBr Visible Light Catalyst

[0057] (1) 1.455g (3mmol) (BiNO 3 )·5H 2 O was dissolved in 40ml of 5% HAc solution, dispersed by ultrasonic and stirred for 5min until the solution was clarified to obtain (BiNO 3 )·5H 2 O solution.

[0058] (2) 0.357g (3mmol) KBr was added to (BiNO 3 )·5H 2 O solution and stirring (theoretical amount of BiOBr generated is 0.914g), the stirring speed is 250rpm·min -1 , the stirring time was 20min, and a suspension with a white precipitate was obtained, and the suspension was washed with 80ml of deionized water until neutral.

[0059] (3) Add 40ml of deionized water after pouring off the washing liquid, and carry out microwave heating reaction. Wash by centrifugation for 3 times, and then dry in vacuum at 80° C. for 12 h to obtain a spherical BiOBr visible photocatalyst.

Embodiment 2

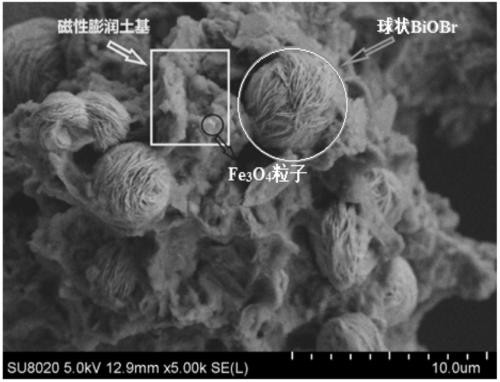

[0061] Preparation of Magnetic Bentonite Base

[0062] (1) Dissolve 0.0914g of bentonite in 20ml of ultrapure water, disperse and stir for 20min by ultrasonic to obtain bentonite suspension;

[0063] (2) 0.10812g (0.4mmol) FeCl 3 ·6H 2 O and 0.04g (0.2mmol) FeCl 2 4H 2 O dissolved in 60ml deionized water (theoretical Fe 3 o 4 The production amount is 0.0427g), first microwave preheating for 3min, then add 8ml of ammonia water, then carry out microwave heating reaction for 30min, the microwave parameters are: 60°C, 600W; then aging and stirring, the stirring rate is 200rpm·min -1 , the stirring time is 10min, and then cooled to room temperature to obtain a magnetic fluid containing magnetic precipitation;

[0064] (3) Wash the magnetic fluid once with 200 ml of deionized water under the condition of an external magnetic field, then add it into the bentonite suspension and stir for 3 hours to obtain the magnetic fluid, and then dry it to obtain the magnetic bentonite base....

Embodiment 3

[0066] Preparation of BiOBr-MB with 2.5% magnetic content

[0067] A preparation method of spherical BiOBr (abbreviated: BiOBr-MB) supported by magnetic bentonite with 2.5% magnetic content, the method is: using potassium bromide as bromine source, bismuth nitrate pentahydrate as bismuth source, and acetic acid as solvent to prepare BiOBr Precursor, with magnetic bentonite as the loading matrix and water as the dispersant, the BiOBr precursor is first embedded in the interlayer of the magnetic bentonite base and deposited on the surface of the magnetic bentonite base, and then microwave-assisted hydrothermal method is used to pass through high-temperature pressurized The function realizes self-assembly in situ, and BiOBr-MB with 2.5% magnetic content is obtained. Specific steps are as follows:

[0068] (1) Preparation of BiOBr precursor solution: 1.455g (3mmol) (BiNO 3 )·5H 2 O was added to 40ml of 5% HAc solution, ultrasonically dispersed and stirred for 5min until the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com