Visible-light-response vanadate photocatalytic material as well as preparation method and application thereof

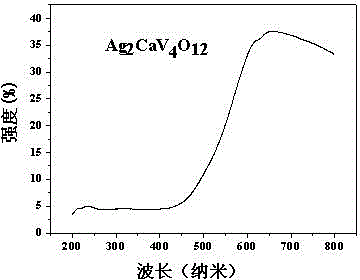

A photocatalytic material and visible light technology, applied in the direction of light water/sewage treatment, etc., can solve the problems that have not been reported, and achieve the effect of short reaction time, fine powder particles, and good photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

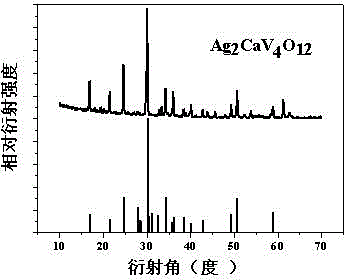

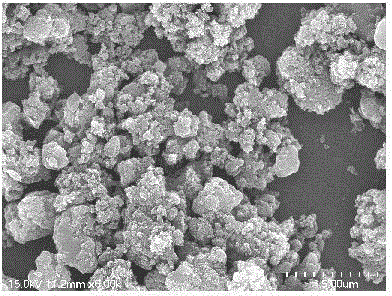

[0038] Embodiment 1: In order to obtain the composite oxide Ag used in the present invention 2 CaV 4 o 12 , prepared by a high-temperature solid-phase method, that is, mixing various oxides or carbonates as raw materials according to the stoichiometric ratio of the target composition, and then synthesizing in an air atmosphere under normal pressure. In addition, in order to effectively utilize light, the size of the photocatalyst in the present invention is preferably at the micron level, or even nanoparticles, and the specific surface area is relatively large, while the oxide powder prepared by the solid-phase synthesis method has relatively large particles and The surface area is small, but the particle diameter can be reduced by pulverizing means such as a ball mill, and the specific steps are as follows.

[0039] First, according to the chemical formula Ag 2 CaV 4 o 12 , respectively weighed silver carbonate Ag 2 CO 3 : 2.758 g, calcium carbonate CaCO 3 : 1.001 g, ...

Embodiment 2

[0046] Embodiment 2: adopt high temperature solid state method to prepare Ag 2 CaV 4 o 12 ,Specific steps are as follows.

[0047] First, according to the chemical formula Ag 2 CaV 4 o 12 , respectively weighed silver carbonate Ag 2 CO 3 : 2.758 g, Calcium Hydroxide Ca(OH) 2 : 0.741 g, vanadium pentoxide V 2 o 5 : 3.640 grams, ground in an agate mortar and mixed uniformly, select the air atmosphere for pre-calcination, the pre-calcination temperature is 400 ℃, the calcination time is 6 hours, then cooled to room temperature, and taken out.

[0048] Then, the mixture calcined for the first time was thoroughly mixed and ground evenly, and then calcined for the second time in an air atmosphere at a calcination temperature of 500° C. for 7 hours, then cooled to room temperature, and taken out.

[0049] Finally, the above mixture is fully ground again and placed in a muffle furnace, and calcined in an air atmosphere at a calcination temperature of 800°C and a calcination ...

Embodiment 3

[0051] Embodiment 3: adopt high temperature solid state method to prepare Ag 2 CaV 4 o 12 ,Specific steps are as follows.

[0052] First, according to the chemical formula Ag 2 CaV 4 o 12 , respectively weighed silver carbonate Ag 2 CO 3 : 2.758 g, calcium sulfate CaSO 4 : 1.641 g, ammonium metavanadate NH 4 VO 3 : 4.679 grams, ground in an agate mortar and mixed evenly, select the air atmosphere for pre-calcination, the pre-calcination temperature is 350 ° C, the calcination time is 7 hours, then cooled to room temperature, and taken out.

[0053] Then, the mixture calcined for the first time was thoroughly mixed and ground evenly, and then calcined for the second time in an air atmosphere at a calcination temperature of 450° C. for 8 hours, then cooled to room temperature, and taken out.

[0054] Finally, the above mixture is fully ground again and placed in a muffle furnace for calcination in an air atmosphere at a calcination temperature of 750°C and a calcinatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com