Imprinting-doped mesoporous TiO2 microspheres and preparation method and application thereof

A microsphere and mesoporous technology, applied in chemical instruments and methods, water/sludge/sewage treatment, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of insufficient photocatalytic activity and low quantum efficiency. , narrow absorption wavelength range and other problems, to achieve the effect of high-efficiency photocatalytic degradation, high photocatalytic efficiency, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

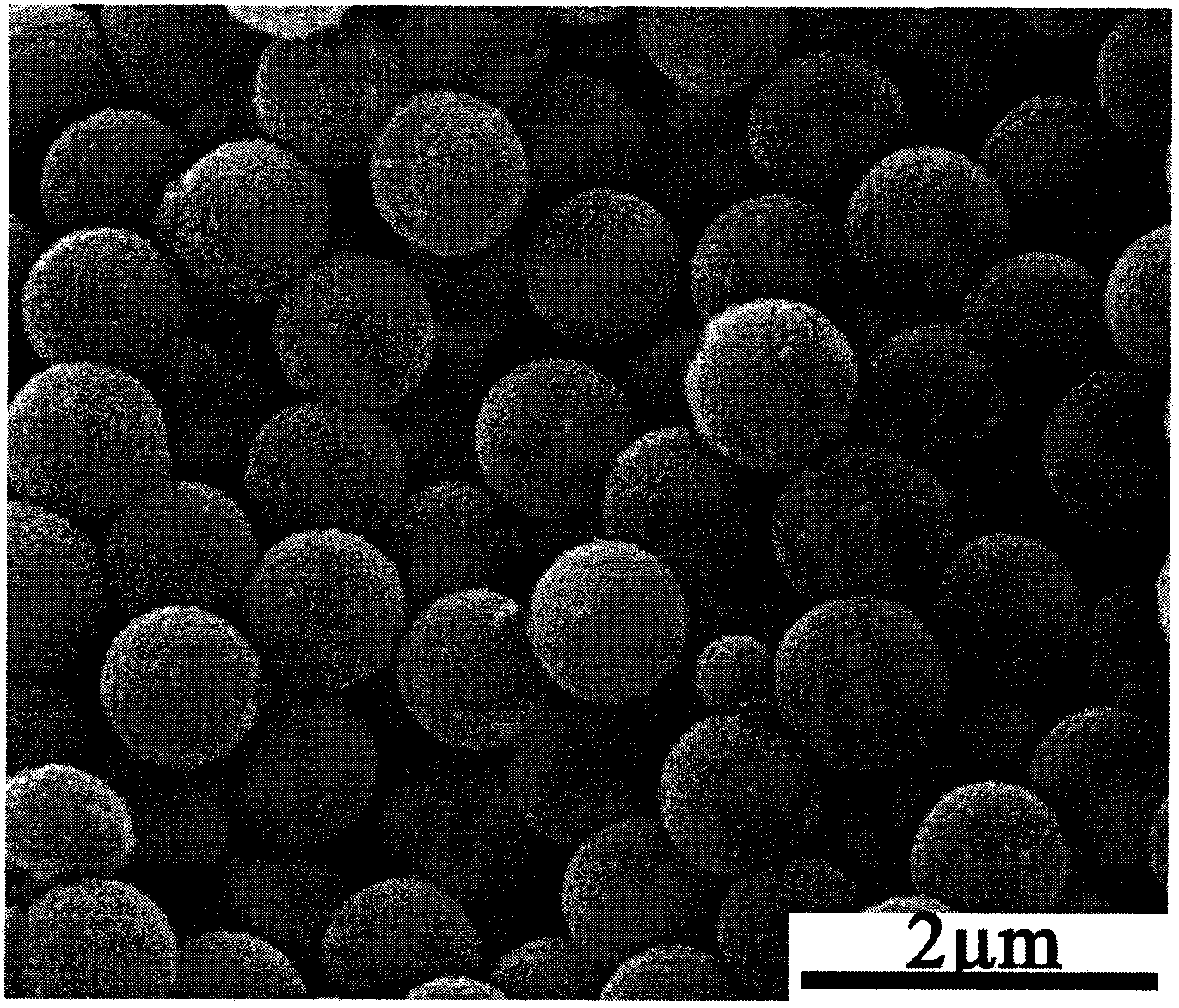

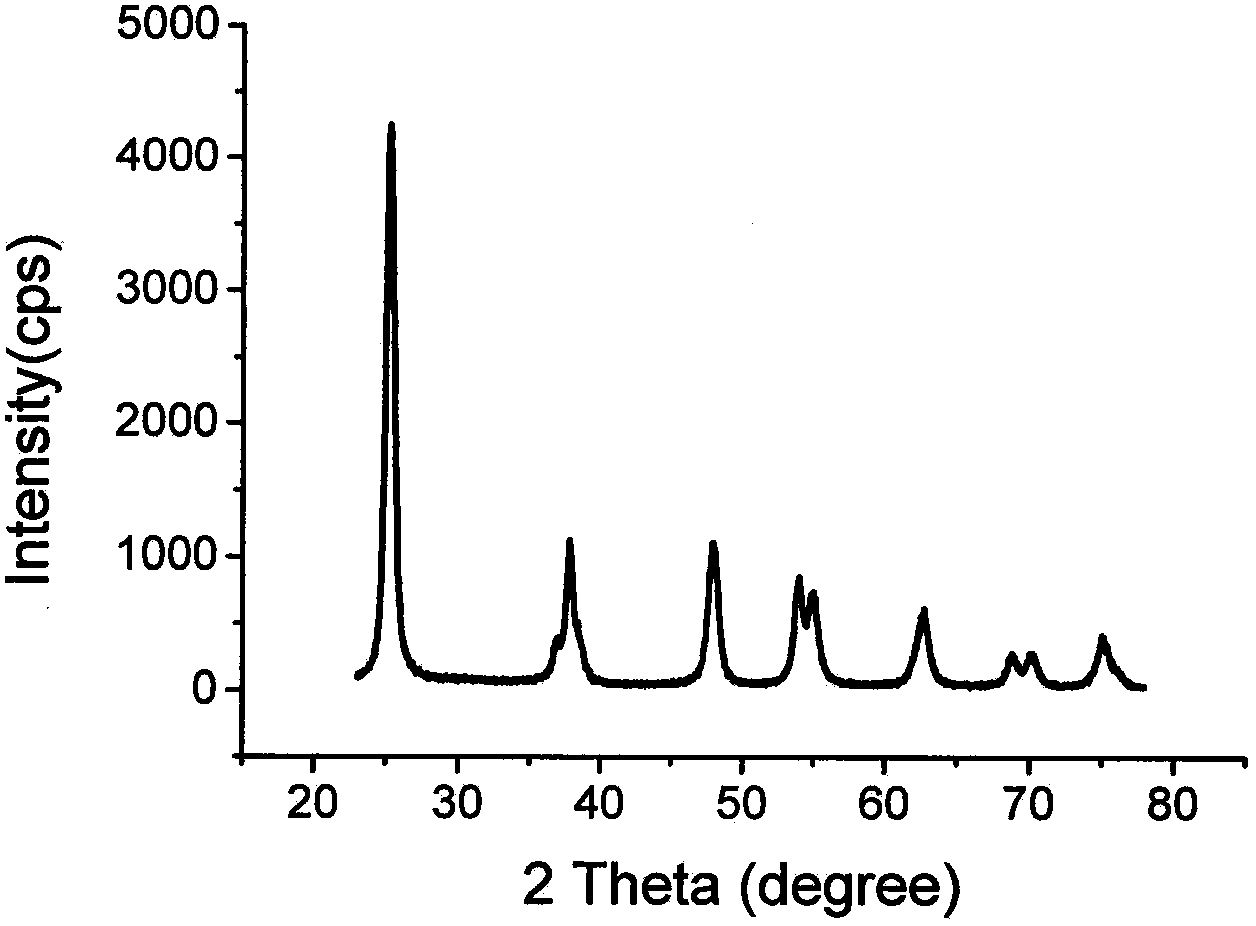

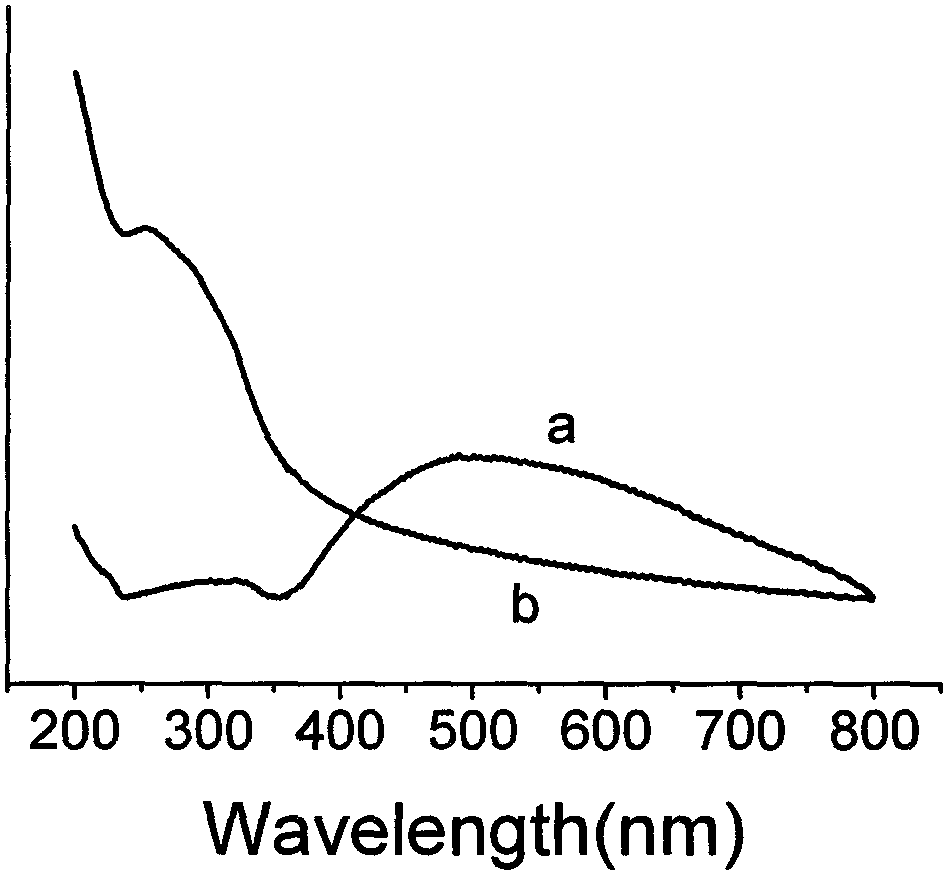

[0042] 1. In the first step, dissolve 2ml of butyl titanate in 150ml of ethanol, add 0.2g of dodecylamine and 0.8g of water, add 0.2g of BPA as imprinted molecules while stirring, and add zinc nitrate hexahydrate while stirring, The molar ratio of zinc nitrate hexahydrate to butyl titanate was 0.2%, and stirred gently for 5 hours.

[0043] 2. In the second step, the solution obtained in the first step was transferred to a high-temperature and high-pressure reactor, reacted at 120° C. for 5 hours, and then cooled to room temperature.

[0044] 3. In the third step, the solution obtained in the second step is centrifuged, and the obtained precipitate is washed three times with ethanol and ultrapure water respectively, and dried at 40°C.

[0045] 4. In the fourth step, put the dried powder into a muffle furnace and bake at 400°C for 3 hours to obtain imprinted doped mesoporous TiO 2 Microspheres.

[0046] 4mg TiO 2 Added to the mixed solution containing both target pollutant BP...

Embodiment 2

[0048] 1. In the first step, dissolve 3ml of butyl titanate in 150ml of ethanol, add 0.2g of dodecylamine and 0.8g of water, add 0.2g of BPA as imprinted molecules while stirring, and add zinc nitrate hexahydrate while stirring, The molar ratio of zinc nitrate hexahydrate to butyl titanate was 0.2%, and stirred gently for 6 hours.

[0049] 2. In the second step, transfer the solution obtained in the first step to a high-temperature and high-pressure reactor, react at 120° C. for 5 hours, and then cool to room temperature.

[0050] 3. In the third step, the solution obtained in the second step is centrifuged, and the obtained precipitate is washed three times with ethanol and ultrapure water respectively, and dried at 40°C.

[0051] 4. In the fourth step, put the dried powder into a muffle furnace and bake at 400°C for 3 hours to obtain imprinted doped mesoporous TiO 2 Microspheres.

[0052] 4mg TiO 2 Added to the mixed solution containing both target pollutant BPA and non-t...

Embodiment 3

[0054] 1. In the first step, dissolve 4ml of butyl titanate in 150ml of isopropanol, add 0.2g of dodecylamine and 0.8g of water, add 0.2g of BPA as imprinted molecules while stirring, and add nitric acid hexahydrate while stirring Zinc, the molar ratio of zinc nitrate hexahydrate to butyl titanate is 0.2%, and stirred gently for 5 hours.

[0055] 2. In the second step, transfer the solution obtained in the first step to a high-temperature and high-pressure reactor, react at 120° C. for 5 hours, and then cool to room temperature.

[0056] 3. In the third step, the solution obtained in the second step is centrifuged, and the obtained precipitate is washed three times with ethanol and ultrapure water respectively, and dried at 40°C.

[0057] 4. In the fourth step, put the dried powder into a muffle furnace and bake at 400°C for 3 hours to obtain imprinted doped mesoporous TiO 2 Microspheres.

[0058] 4mg TiO 2 Added to the mixed solution containing both target pollutant BPA an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com