Preparation method of composite p-n type heterojunction photocatalyst and VOCs photocatalytic degradation method

A photocatalyst and heterojunction technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as complicated operation and easy aggregation of silver particles , to achieve the effects of not easy to agglomerate, good stability, and high-efficiency photocatalytic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a composite p-n-type heterojunction photocatalyst in this embodiment, the preparation method includes the following steps:

[0029] (1) Under magnetic stirring, add 0.3 g of titanium dioxide to 35 mL of deionized water, and then add dropwise sodium hydroxide to adjust pH=8.5 after mixing evenly;

[0030] (2) the solution obtained in step (1) was purged with nitrogen and air-sealed, and then slowly dripped 0.14 mL of silver nitrate (168.3 g / L) to stir the solution for subsequent use;

[0031] (3) Add 1.4 mL of sodium borohydride (9.38 g / L) dropwise to the solution in (2), stir evenly, and let stand for 16 hours

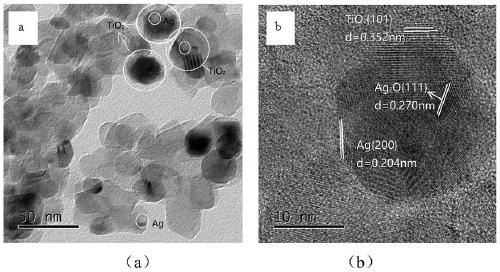

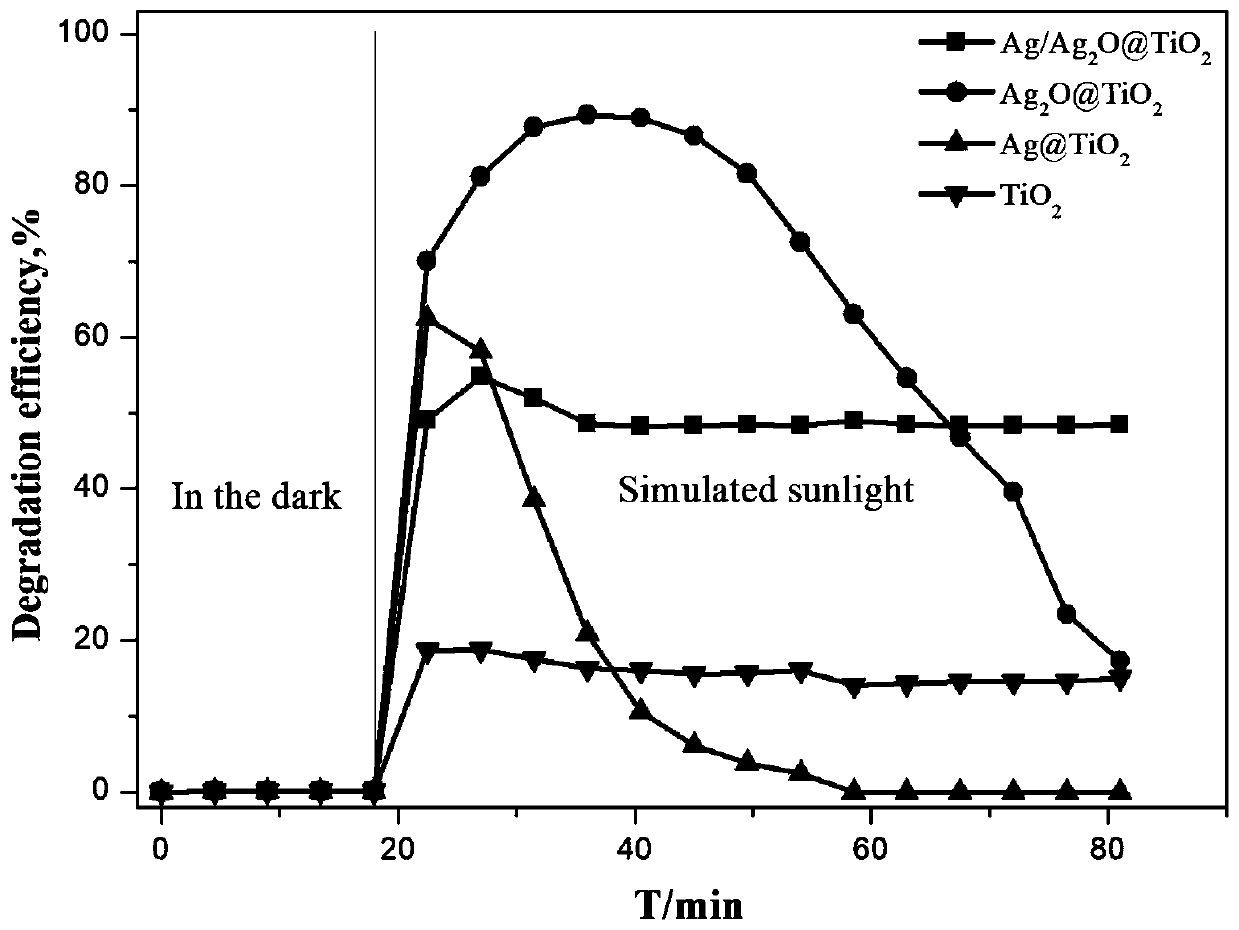

[0032] (4) the material obtained after standing in step (3) is washed several times with deionized water and then freeze-dried to obtain a silver / silver oxide co-doped titanium dioxide composite p-n-type heterojunction photocatalyst, such as figure 1 (a), the surface of the catalyst is deposited with spherical nano-silver element, figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com