Method for treating landfill leachate with photocatalytic biosorbent

A biosorbent and landfill leachate technology, applied in biological water/sewage treatment, special compound water treatment, chemical instruments and methods, etc., can solve the problems of complex process, high cost, high equipment requirements, etc., and achieve simplified process , low cost, high biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

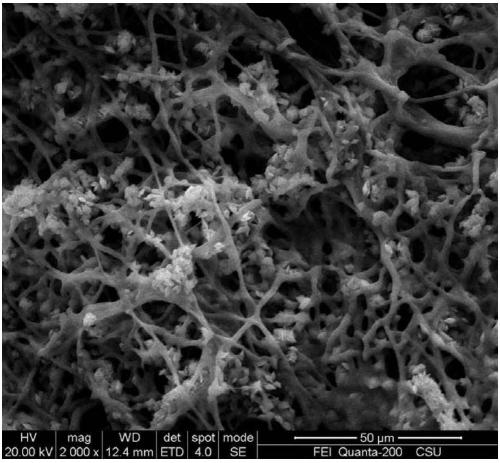

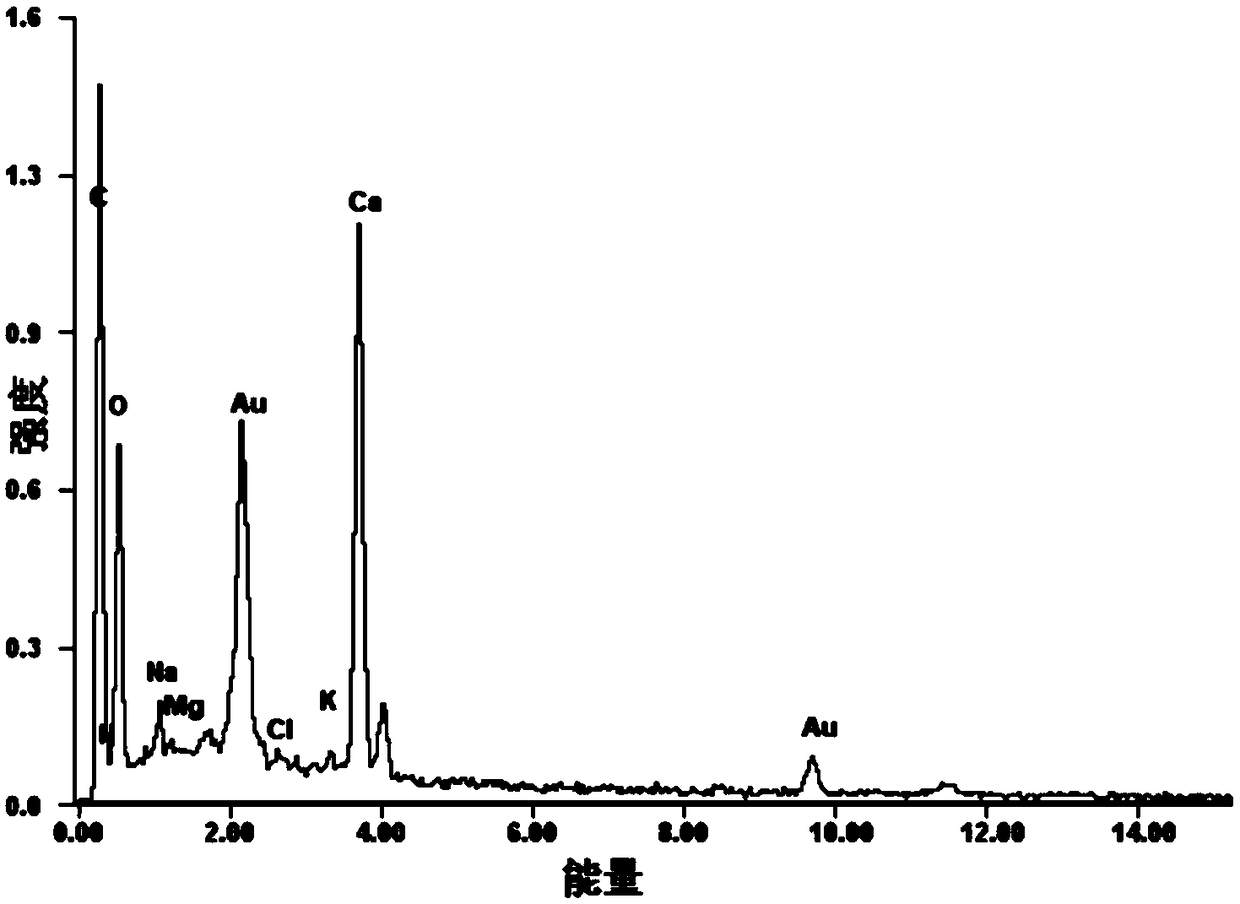

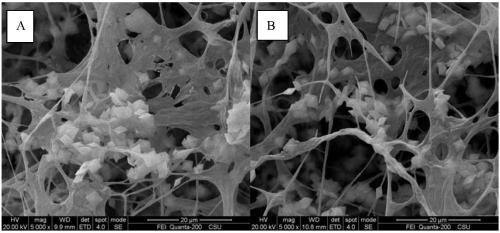

[0034] A kind of photocatalytic biosorbent of the present invention, this photocatalytic biosorbent comprises Phanerochaete chrysosporium bacterial ball, graphite type C 3 N 4 and calcium alginate; graphite type C 3 N 4 The hyphae of Phanerochaete chrysosporium balls are coated by calcium alginate.

[0035] A preparation method of the above-mentioned photocatalytic biosorbent of the present embodiment, comprising the following steps:

[0036](1) Weigh 10g of urea into a 100mL crucible, cover the lid, and then wrap it tightly with tin foil; place the above sample in the middle of the muffle furnace for calcination. The calcination is specifically as follows: heating the urea from room temperature to 550° C. at a heating rate of 8° C. / min, and then keeping the temperature at 550° C. for constant temperature calcination for 3 hours. After cooling in the air, grind the sample in a mortar for 5 minutes, and the resulting bright yellow powder is graphite type C 3 N 4 Material....

Embodiment 2

[0045] A method for treating landfill leachate with a photocatalytic biosorbent of the present invention, comprising the following steps:

[0046] (1) Dilute the original landfill leachate with ultrapure water to obtain landfill leachate with a certain initial concentration of TOC. The initial TOC concentration can be 180mg / L, 210mg / L, 240mg / L, 270mg / L, 300mg / L respectively.

[0047] (2) Add the photocatalytic biosorbent obtained in Example 1 to the landfill leachate of the initial concentration TOC obtained in step (1), and the amount of photocatalyst biosorbent added is to add photocatalytic biosorbent in every 100mL landfill leachate 3.0g of the solution was used for light vibration adsorption degradation, wherein the intensity of light was 20Lux, the temperature of vibration adsorption degradation was 37°C, the oscillation speed of vibration adsorption degradation was 160r / min, and the time of vibration adsorption degradation was 72h.

[0048] (3) After the vibration adsor...

Embodiment 3

[0052] A method for treating landfill leachate with a photocatalytic biosorbent of the present invention, comprising the following steps:

[0053] (1) Dilute the original landfill leachate with ultrapure water to obtain landfill leachate with a certain initial concentration of TOC, and the initial TOC concentration can be 240mg / L.

[0054] (2) Add the photocatalytic biosorbent obtained in Example 1 to the landfill leachate with an initial concentration of TOC obtained in step (1), and the amount of photocatalyst biosorbent added is respectively 100 mL of landfill leachate with photocatalytic biosorbent Adsorbents of 2.0g, 3.0g, and 4.0g were subjected to light oscillation adsorption degradation, where the intensity of light was 20Lux, the temperature of oscillation adsorption degradation was 37°C, the oscillation speed of oscillation adsorption degradation was 160r / min, and the time of oscillation adsorption degradation was 72h.

[0055] (3) After the vibration adsorption deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com