Method of preparing zinc oxide-reduced graphene oxide composite material

A composite material and zinc oxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, separation methods, etc., can solve problems such as high energy consumption, high temperature, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

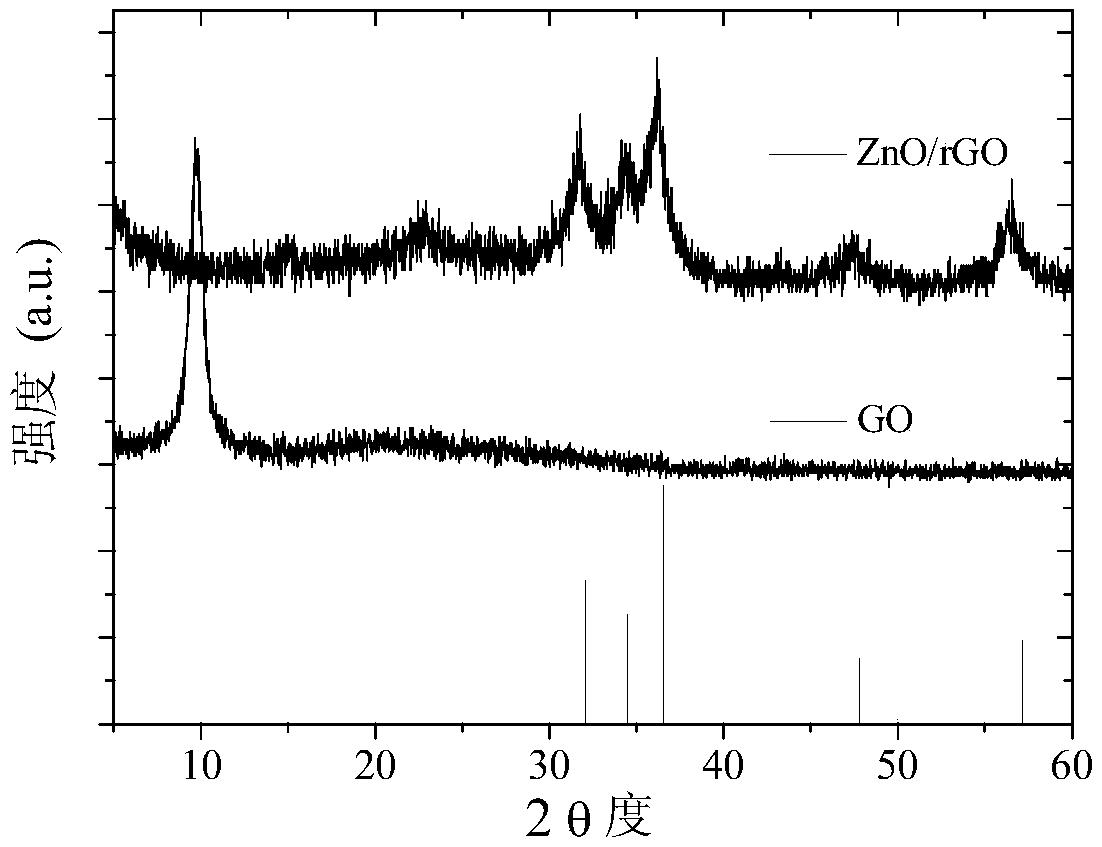

Image

Examples

preparation example Construction

[0034] The preparation of graphene oxide is known to those skilled in the art. For example, graphene oxide can be produced by isolating (exfoliating) graphite oxide. Graphite oxide and graphene oxide are negatively charged due to the oxygen functional groups present therein, so graphite oxide can be separated into graphene oxide in a polar solvent. This can be facilitated, for example, by using ultrasound. Graphite oxide is hydrophilic. Exfoliated graphene oxide forms an excellently dispersed aqueous suspension.

[0035] The preparation of graphite oxides is likewise known to those skilled in the art; graphite oxides are usually prepared by oxidation of graphite. This oxidation introduces oxygen atoms into the graphite; in particular alcohol, epoxy, carbonyl and carboxyl groups are formed. These groups increase the distance between the layers, which can be more easily separated from each other. In addition, the oxidized graphite layer becomes more hydrophilic and has bett...

Embodiment 1

[0089] 4mg of the obtained graphite oxide was uniformly dispersed in 10mL of acetone, and then 40mg of photoinitiator bis-2,6-difluoro-3-pyrrolephenyl titanocene, 80mg of zinc sulfide as zinc source and 2mL of ammonia as a weak base were added and The obtained mixture was dispersed uniformly by ultrasonic (power 20W) to obtain a dispersion.

[0090] Transfer the dispersion to a transparent test tube, place it in a dark environment at a distance of 10 cm from the ultraviolet light source, and irradiate for about 10 minutes (the energy density of the irradiation is 100 mW / cm 2 , where the energy density was measured using an exposure meter from the Photoelectric Instrument Factory of Beijing Normal University), and the dispersion gradually precipitated. The precipitate-containing dispersion was centrifuged, washed three times with ethanol and dried in a vacuum oven at 65 °C for 5 hours to obtain the final composite. The photodegradation efficiency of the obtained zinc oxide-red...

Embodiment 2

[0092] Repeat Example 1, but change the graphite oxide dispersion solvent into ethanol; change the photoinitiator into benzil; change the zinc source into 460mg zinc phosphate; change the weak base into triethylamine. The photodegradation efficiencies of the obtained composites are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com