Color-masking zirconia veneer

A zirconia and opaque technology, which is used in compression mold cups, dental prostheses, dentistry, etc., can solve problems such as reducing the reliability of zirconia restorations, achieve good aesthetic restoration effects, and improve specific surface and surface roughness. , the effect of high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] 2. Preparation of veneer raw materials:

[0072] 2.1 white zirconia

[0073] The slurry used for veneer molding is made by liquid phase co-precipitation method or hydrothermal-hydrolysis method.

[0074] 2.1.1 The liquid-phase co-precipitation method is specifically:

[0075] Slowly drop the precursor body fluid containing yttrium and zirconium into the precipitant, stir vigorously to make it fully react, and age for more than 8-12 hours after the reaction, quickly separate with a centrifuge, vacuum filter the precipitate, and use distilled water, ethanol After washing and drying, a precursor of yttrium partially stabilized zirconia with a yttrium content of 2-6mol% is obtained as the main phase; the precursor is mixed with a dispersant accounting for 1-3% of the weight of the precursor, and deionized water is added to form a solid phase Slurry with a content of 2-15vol%, adjust the pH to 3-6, stir and mix, and then add it to the planetary mill for ball milling for 10...

manufacture example

[0107] Alumina-doped Y Partially Stabilized ZrO 2 The sol preparation method is: alumina (1-5mol%) doped with Y (2-6mol%) to partially stabilize ZrO 2 The example of sol manufacturing is as follows: The method of reverse dripping is used to prepare alumina-doped Y-stabilized ZrO 2 Sol, the prepared precipitant NH 4 HCO 3 (10-50%)+NH 3 ·H 2 O solution (50-90%) is placed in the Erlenmeyer flask, and the Erlenmeyer flask is placed in a magnetic stirrer or a constant temperature water bath reactor with stirring, and the prepared Al-containing 3+ , Y 3+ 、Zr 4+ The mother liquor includes zirconium hydroxide (ZrO(OH) 2 ·nH 2 O≥99%), zirconium oxychloride (ZrOCl 2 ·8H 2 O≥99%), zirconium nitrate (Zr(NO 3 ) 4 ·5H 2 One of O≥99%); Yttrium nitrate Y (NO 3 ) 3 ·6H 2 O, yttrium chloride (YCI 3 ·6H 2 One of O≥99.99%); aluminum chloride (AlCl 3 ≥99%), aluminum nitrate (Al(NO 3 ) 3 9H 2 One of O), slowly drop into the precipitant, and vigorously stir to make it fully rea...

Embodiment 1

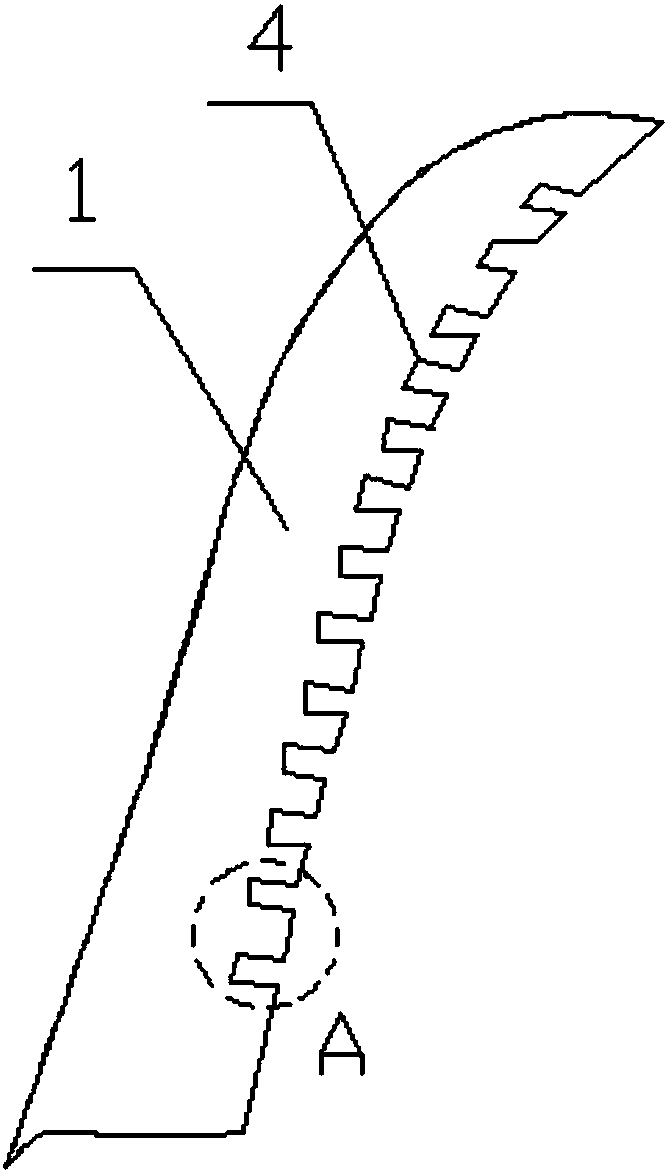

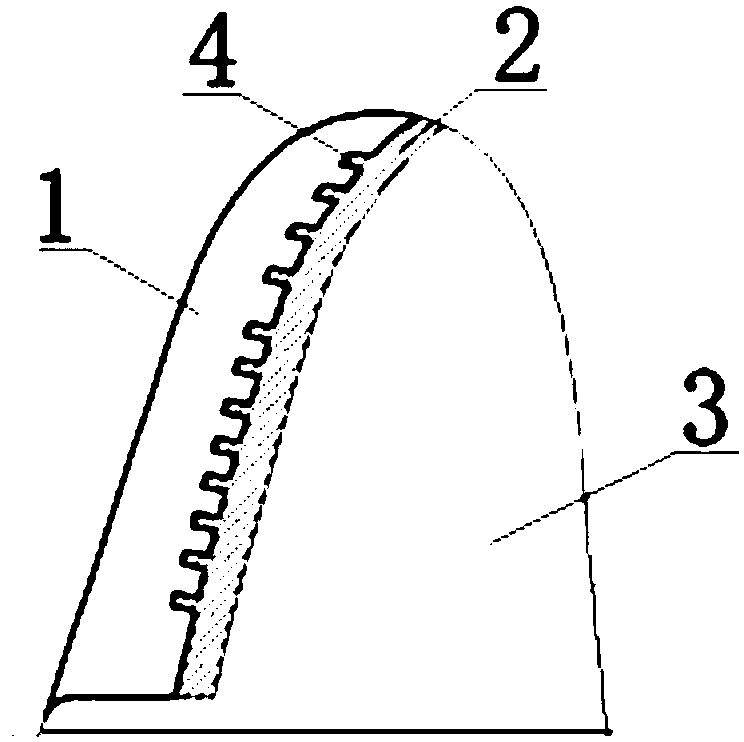

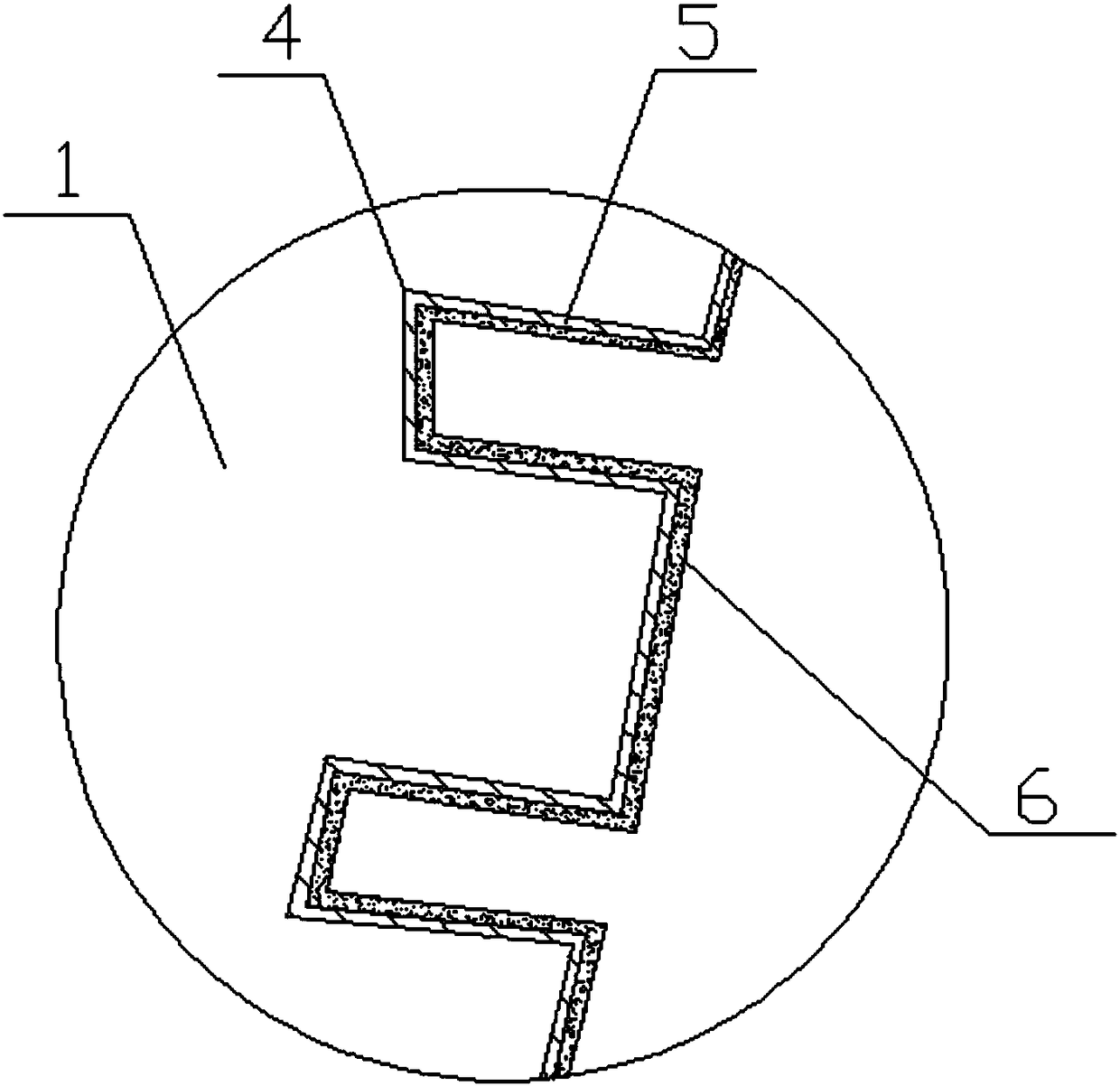

[0126] Example 1. Abutment tooth A2 color veneer restoration one

[0127] Using one of the slurries recorded in 2.1.1-2.1.3 as a raw material, based on the pure-form manufacturing principles of computer-aided design (CAD) and computer-aided manufacturing (CAM), the white oxide was prepared by layer-by-layer additive method of colloidal deposition The zirconium restoration body is milled on the bonding surface (or wearing tooth surface) of the zirconia veneer green body for bonding with natural teeth to form micro-textures for improving the specific surface area and surface roughness: use SUM3D is used for processing programming, and the grid tool path is set to be vertically staggered, the grid depth is 0.03mm, the grid spacing is 0.3mm, and the grid range is 2mm from the edge, such as Figure 5 . The tool is a 0.6mm carbide ball end milling cutter, the spindle speed is 15000rpm, the milling feed is 1000mmpm, and the processing program is generated. Import the processing pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com