Bi2O2CO3/PPy/g-C3N4 compound photocatalyst and preparation method and application thereof

A composite light and catalyst technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Composite, low utilization rate of sunlight and other problems, achieve good degradation effect, good light and heat stability, and improve the effect of response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

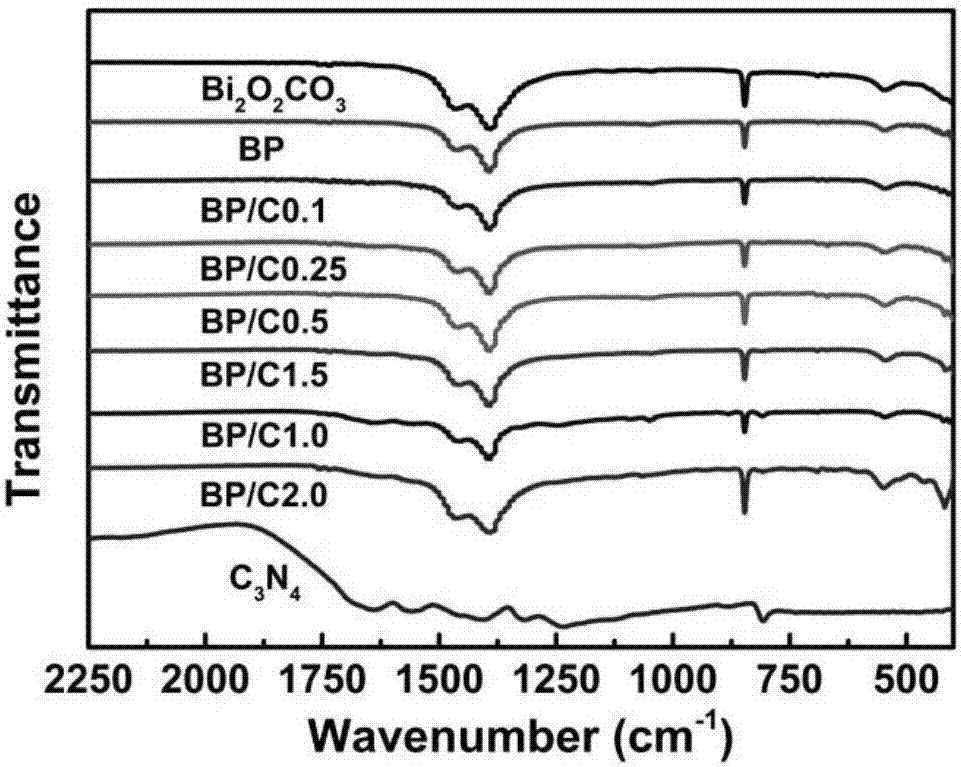

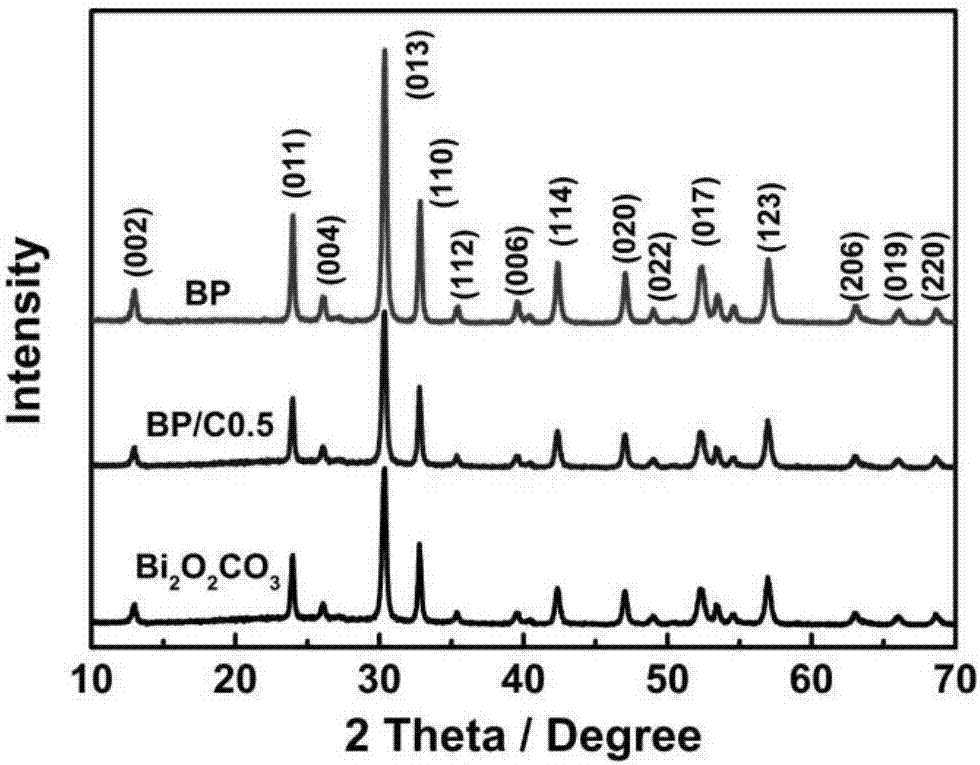

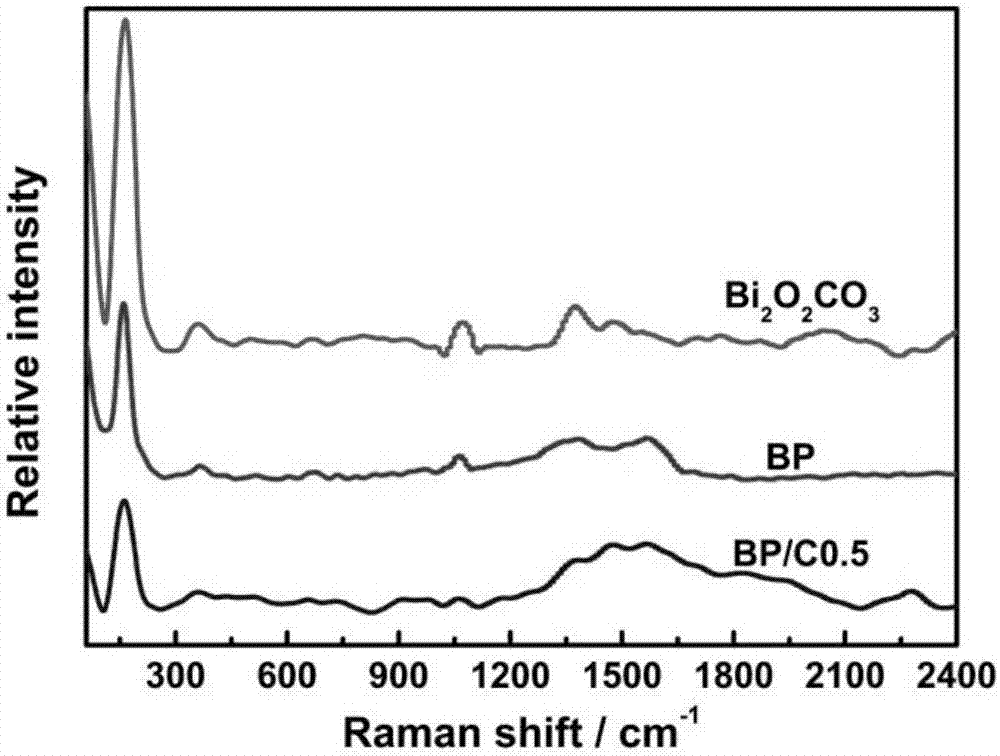

[0034] bismuth subcarbonate Bi 2 o 2 CO 3 (200 mg) and polypyrrole PPy (2 mg) were ultrasonically dispersed (2 hours) in the polar organic solvent tetrahydrofuran (20 mL), and after uniform dispersion, reflux reaction was carried out at 66° C. for 24 hours. After the reaction, after the reaction solution was cooled to room temperature, the reaction solution was filtered with a 0.45 μm nylon membrane, washed with deionized water and ethanol respectively, and then dried under vacuum at room temperature for 12 hours to obtain a gray powder product, namely Bi 2 o 2 CO 3 / PPy(BP) composite photocatalyst.

[0035] Among them, bismuth subcarbonate Bi 2 o 2 CO 3 The mass ratio to polypyrrole PPy is 100:1.

Embodiment 2

[0037] The BP composite material (80 mg) prepared in Example 1 was ultrasonically dispersed in the polar organic solvent tetrahydrofuran (20 mL), and the ultrasonic time was 1 hour. Then add g-C 3 N 4 (0.08 mg) was sonicated for 1 hour to disperse evenly, and reflux reaction was carried out at 66° C. for 12 hours. After the reaction, after the reaction solution was cooled to room temperature, the reaction solution was filtered with a 0.45 μm nylon membrane, washed with deionized water and ethanol respectively, and then dried under vacuum at room temperature for 12 hours to obtain a gray powder product, namely BP / C0.1 composite photocatalyst.

[0038] Among them, BP and g-C 3 N 4 The mass ratio is 1000:1.

Embodiment 3

[0040] The BP composite material (80 mg) prepared in Example 1 was ultrasonically dispersed in the polar organic solvent tetrahydrofuran (20 mL), and the ultrasonic time was 1 hour. Then add g-C 3 N 4 (0.2 mg) was sonicated for 1 hour to disperse evenly, and reflux reaction was carried out at 66° C. for 12 hours. After the reaction, after the reaction solution was cooled to room temperature, the reaction solution was filtered with a 0.45 μm nylon membrane, washed with deionized water and ethanol respectively, and then dried under vacuum at room temperature for 12 hours to obtain a gray powder product, namely BP / C0.25 composite photocatalyst.

[0041] Among them, BP and g-C 3 N 4 The mass ratio is 1000:2.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com