Bismuth subcarbonate/sepiolite composite photocatalyst and preparation method thereof

A technology of bismuth oxycarbonate and sepiolite, which is applied in the field of photocatalytic degradation of organic pollutants, and can solve problems such as Sepiolite composite photocatalysts that have not yet been developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

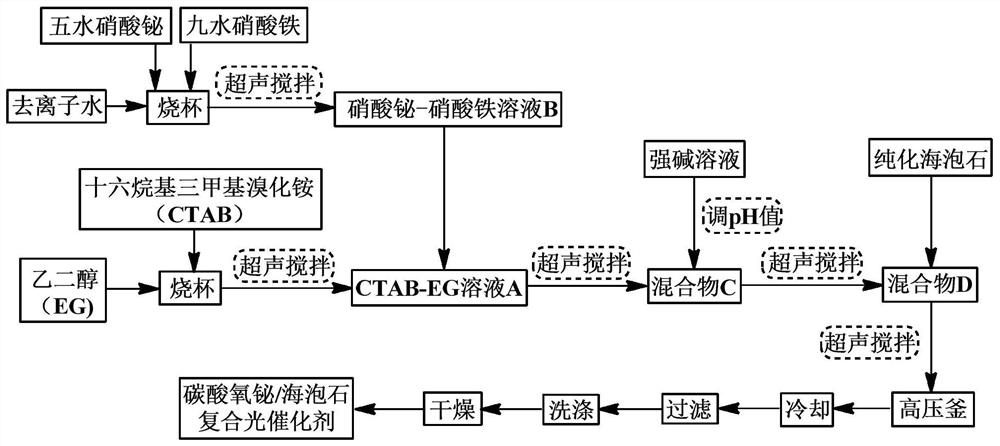

[0032] (1) Take 5.47g of cetyltrimethylammonium bromide and add it to 120mL of ethylene glycol, stir it ultrasonically for 20 minutes, and prepare cetyltrimethylammonium bromide-ethylene diethyl ammonium bromide with a concentration of 0.125mol / L Alcoholic solution A;

[0033] (2) Take 2.94g of bismuth nitrate pentahydrate with a content of 99.0% and 2.46g of ferric nitrate nonahydrate with a content of 98.5% and add them to 300mL of deionized water at the same time, stir ultrasonically for 20min to dissolve into Bi 3+ The concentration is 0.02mol / L, Fe 3+ Concentration is the bismuth nitrate-iron nitrate mixed solution B of 0.020mol / L;

[0034] (3) Slowly add the mixed solution B prepared in step (2) to the solution A prepared in step (1), stir ultrasonically for 15 minutes, then adjust the pH to 10.5 with 10mol / L KOH solution, and continue ultrasonically stirring at room temperature 4h, to obtain mixture C;

[0035] (4) Add 0.24 g of purified sepiolite to the mixture C ob...

Embodiment 2

[0038] (1) Take 5.47g of cetyltrimethylammonium bromide and add it to 100mL of ethylene glycol, stir it ultrasonically for 25 minutes, and prepare cetyltrimethylammonium bromide-ethylene diethyl ammonium bromide with a concentration of 0.15mol / L Alcoholic solution A;

[0039] (2) Take 2.94g of bismuth nitrate pentahydrate with a content of 99.0% and 2.41g of ferric nitrate nonahydrate with a content of 98.5% and add them to 240mL of deionized water at the same time, stir ultrasonically for 25min to dissolve into Bi 3+ The concentration is 0.025mol / L, Fe 3+ Concentration is the bismuth nitrate-iron nitrate mixed solution B of 0.024mol / L;

[0040] (3) Slowly add the mixed solution B prepared in step (2) dropwise to the solution A prepared in step (1), stir ultrasonically for 20min, then adjust the pH to 10.3 with 12mol / L KOH solution, and continue ultrasonically stirring at room temperature 3.5h, to obtain mixture C;

[0041] (4) Add 0.29 g of purified sepiolite to the mixtur...

Embodiment 3

[0044] (1) Take 5.47g of cetyltrimethylammonium bromide and add it to 75mL of ethylene glycol, stir it ultrasonically for 30 minutes, and prepare cetyltrimethylammonium bromide-ethylene diol with a concentration of 0.20mol / L Alcoholic solution A;

[0045] (2) Take 2.94g of bismuth nitrate pentahydrate with a content of 99.0% and 2.34g of ferric nitrate nonahydrate with a content of 98.5% and add them to 200mL of deionized water at the same time, stir ultrasonically for 25min to dissolve into Bi 3+ The concentration is 0.030mol / L, Fe 3+ Concentration is the bismuth nitrate-iron nitrate mixed solution B of 0.0285mol / L;

[0046] (3) Slowly add the mixed solution B prepared in step (2) to the solution A prepared in step (1), stir ultrasonically for 25min, then adjust the pH to 10.1 with 11mol / L KOH solution, and continue ultrasonically stirring at room temperature 3h, to obtain mixture C;

[0047] (4) Add 0.59 g of purified sepiolite to the mixture C obtained in step (3), and u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com