Preparation method of bismuth subcarbonate-bismuth sulfide heterostructure photocatalytic material

A photocatalytic material, bismuth oxycarbonate technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as insufficient response, achieve low cost, accelerate separation, and improve photocatalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 0.5 g of urea to deionized water, stir to dissolve and add 2.75 mmol of Bi(NO 3 ) 3 ·5H 2 O, mechanical stirring. After the stirring was completed, 3 mmol of sodium sulfide was added to obtain a mixed solution. The mixed solution was mechanically stirred on a magnetic stirrer for 30 min. Transfer the mixed solution to a polytetrafluoroethylene liner, put the liner in a reaction kettle at 200°C and keep it warm for 24 hours for reaction; after the reaction is completed, cool it down to room temperature naturally, centrifuge the product, wash it with water, and wash it with alcohol , and dried at room temperature to obtain a bismuth oxycarbonate-bismuth sulfide heterostructure photocatalytic material.

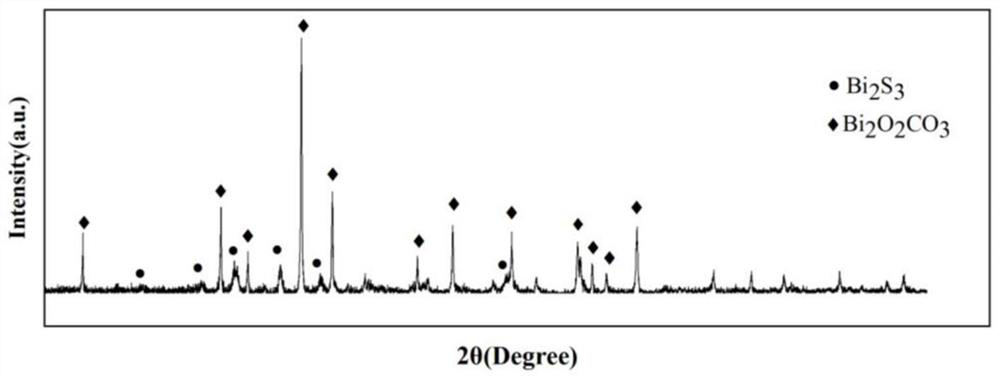

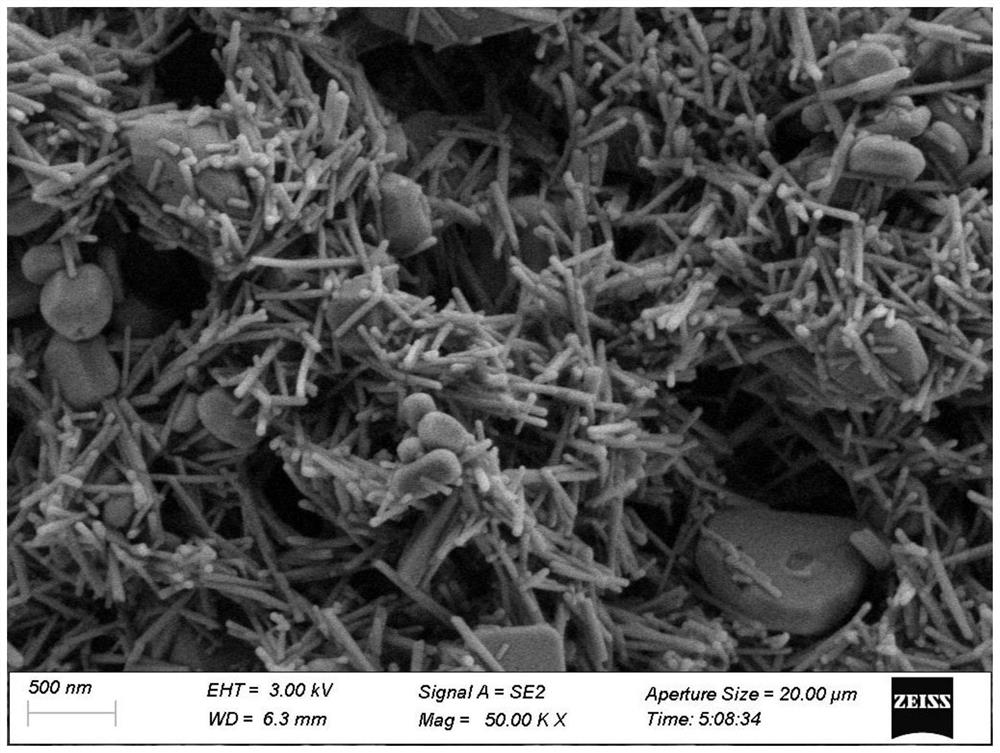

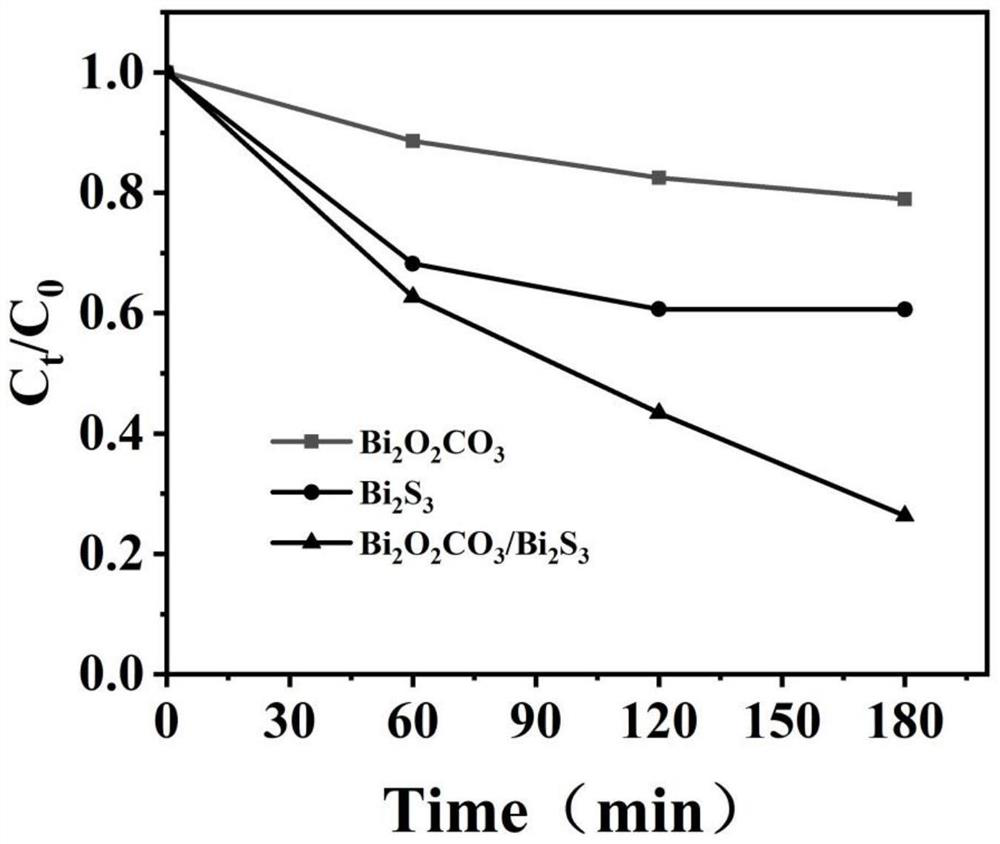

[0029] The XRD patterns of bismuth oxycarbonate-bismuth sulfide heterostructure photocatalytic materials are shown in figure 1 ,Depend on figure 1 It can be seen that this embodiment indeed prepares a bismuth oxycarbonate-bismuth sulfide heterojunction. The SEM ...

Embodiment 2

[0031] Add 0.5 g of urea to deionized water, stir to dissolve and add 2.75 mmol of Bi(NO 3 ) 3 ·5H 2 O, mechanical stirring. After the stirring was completed, 4 mmol of sodium sulfide was added to obtain a mixed solution. The mixed solution was mechanically stirred on a magnetic stirrer for 30 min. Transfer the mixed solution to a polytetrafluoroethylene liner, put the liner in a reaction kettle at 200°C and keep it warm for 24 hours for reaction; after the reaction is completed, cool it down to room temperature naturally, centrifuge the product, wash it with water, and wash it with alcohol , and dried at room temperature to obtain a bismuth oxycarbonate-bismuth sulfide heterostructure photocatalytic material.

Embodiment 3

[0033] Add 0.5 g of urea to deionized water, stir to dissolve and add 2.75 mmol of Bi(NO 3 ) 3 ·5H 2O, mechanical stirring. After the stirring was completed, 4 mmol of sodium sulfide was added to obtain a mixed solution. The mixed solution was mechanically stirred on a magnetic stirrer for 30 min. Transfer the mixed solution to a polytetrafluoroethylene lining, put the lining in a reaction kettle at 180°C and keep it warm for 24 hours for reaction; after the reaction is completed, cool it down to room temperature naturally, centrifuge the product, wash it with water, and wash it with alcohol , and dried at room temperature to obtain a bismuth oxycarbonate-bismuth sulfide heterostructure photocatalytic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com