Stannic oxide electrode ceramic material as well as preparation method thereof

A technology of tin dioxide and ceramic materials, applied in the field of semiconductor ceramics, can solve the problems of prolonging the production cycle, increasing the drying equipment, increasing the drying process, etc., to achieve the effects of enhancing corrosion resistance, less production equipment, and improving bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

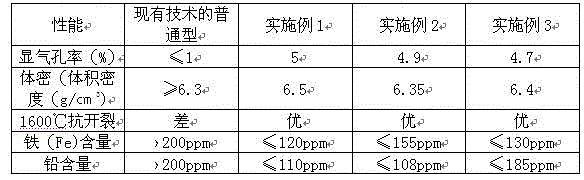

Embodiment 1

[0027] Weigh according to the following ratio of raw materials: main ingredient 100kg of tin dioxide powder (purity 99%), additive 0.2kg of copper oxide (purity 99%), 0.4kg of zinc oxide (purity 99%) 1.1kg of trioxide Antimony (purity 99%), 0.8kg of bismuth subcarbonate, 3kg of sodium silicate aqueous solution with a Baume degree of 52%; after dry mixing the additive powder and tin dioxide powder in a weight ratio of 1:5 , and then put all the remaining tin dioxide powder into the V-shaped mixer for mixing, and then add the prepared sodium silicate aqueous solution with a Baume degree of 52% to the V-shaped mixer for wet mixing for 5 hours, and then use Air flow sieve, sieve through 600-mesh screen three times continuously, put into rubber mold with steel mold after sieving, cold isostatic pressing, hold pressure at 160MPa-200MPa for 3-5 minutes, and press to obtain green body. Body trimming: repair and smooth the surface of the green body;

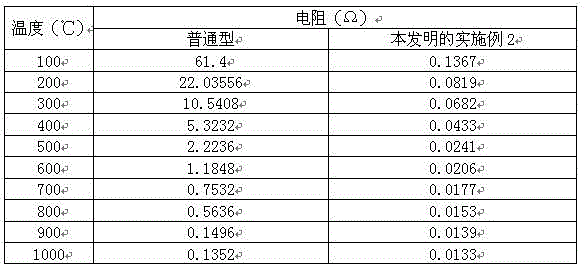

Embodiment 2

[0031] Weigh according to the following ratio of raw materials: main ingredient 100kg of tin dioxide powder (purity 99%), additive 0.3kg of copper oxide (purity 99%), 0.5kg of zinc oxide (purity 99%) 1.2kg of trioxide Antimony (purity 99%), 1.3kg of bismuth subcarbonate, 3.5kg of sodium silicate aqueous solution with a Baume degree of 52%; after dry mixing the additive powder and tin dioxide powder in a weight ratio of 1:5 , and then put all the remaining tin dioxide powder into the V-shaped mixer for mixing, and then add the prepared sodium silicate aqueous solution with a Baume degree of 52% to the V-shaped mixer for wet mixing for 5 hours, and then use Air flow sieve, sieve through 600-mesh screen three times continuously, put into rubber mold with steel mold after sieving, cold isostatic pressing, hold pressure at 160MPa-200MPa for 3-5 minutes, and press to obtain green body. Body trimming: repair and smooth the surface of the green body;

Embodiment 3

[0035] Weigh according to the following ratio of raw materials: main ingredient 100kg of tin dioxide powder (purity 99%), additive 0.5kg of copper oxide (purity 99%), 0.8kg of zinc oxide (purity 99%) 1.4kg of trioxide Antimony (purity 99%), 1.5kg of bismuth subcarbonate, 5kg of sodium silicate aqueous solution with a Baume degree of 52%; after dry mixing the additive powder and tin dioxide powder in a weight ratio of 1:5 , and then put all the remaining tin dioxide powder into the V-shaped mixer for mixing, and then add the prepared sodium silicate aqueous solution with a Baume degree of 52% to the V-shaped mixer for wet mixing for 5 hours, and then use Air flow sieve, sieve through 600-mesh screen three times continuously, put into rubber mold with steel mold after sieving, cold isostatic pressing, hold pressure at 160MPa-200MPa for 3-5 minutes, and press to obtain green body. Body trimming: repair and smooth the surface of the green body;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com