Preparation and application of bismuth oxychloride as photocatalyst

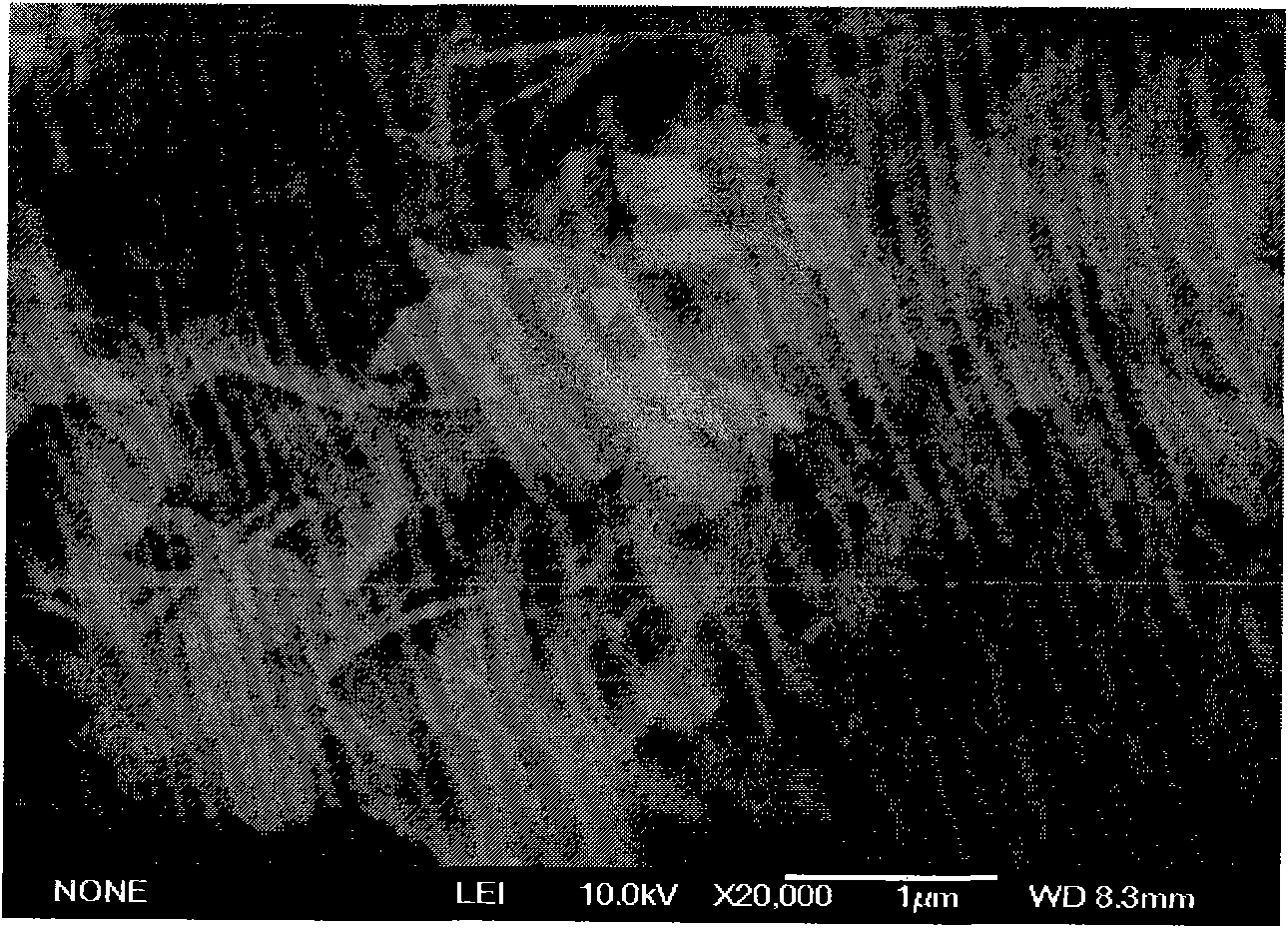

A technology of photocatalyst and bismuth oxychloride, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of long production cycle of bismuth oxychloride, small specific surface area of particles, complex process, etc. , to achieve the effects of low cost, good dispersion and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

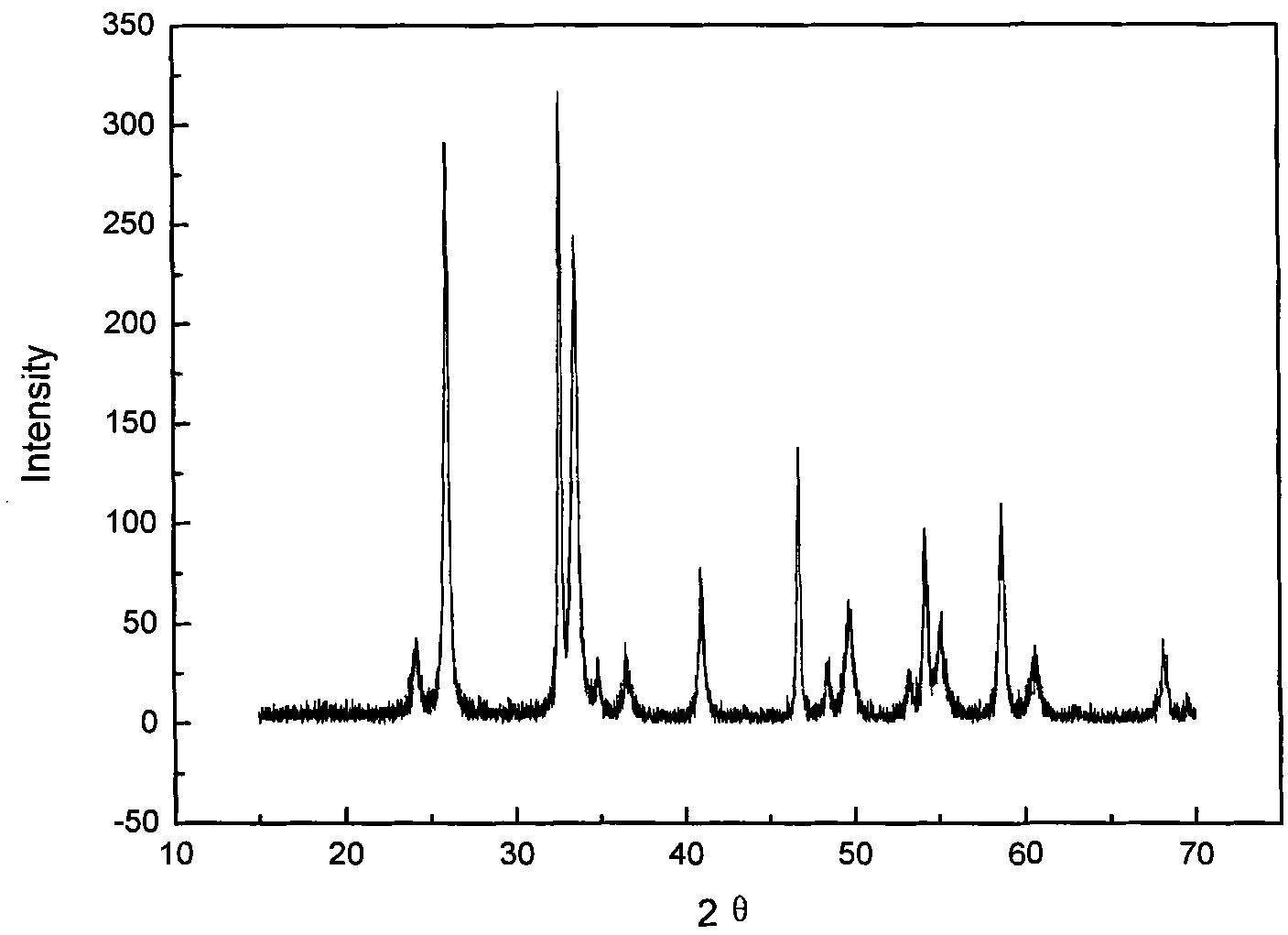

Method used

Image

Examples

Embodiment approach 1

[0023] 1) Weigh 1 gram of analytically pure BiCl 3 placed in 0.1mol·L -1 Dilute hydrochloric acid 50mL, make BiCl 3 Fully dissolve and keep the solution in a transparent state;

[0024] 2) Add 0.1mol·L under magnetic stirring -1 urea solution 9mL and slowly drop Na 2 CO 3 solution, the pH value is controlled at 7, and the stirring reaction time is 1 hour;

[0025] 3) Filtrating the suspension solution obtained in step 2), washing the obtained solid phase product with distilled water, and then drying at a temperature of 50° C. to obtain the bismuth oxychloride photocatalyst.

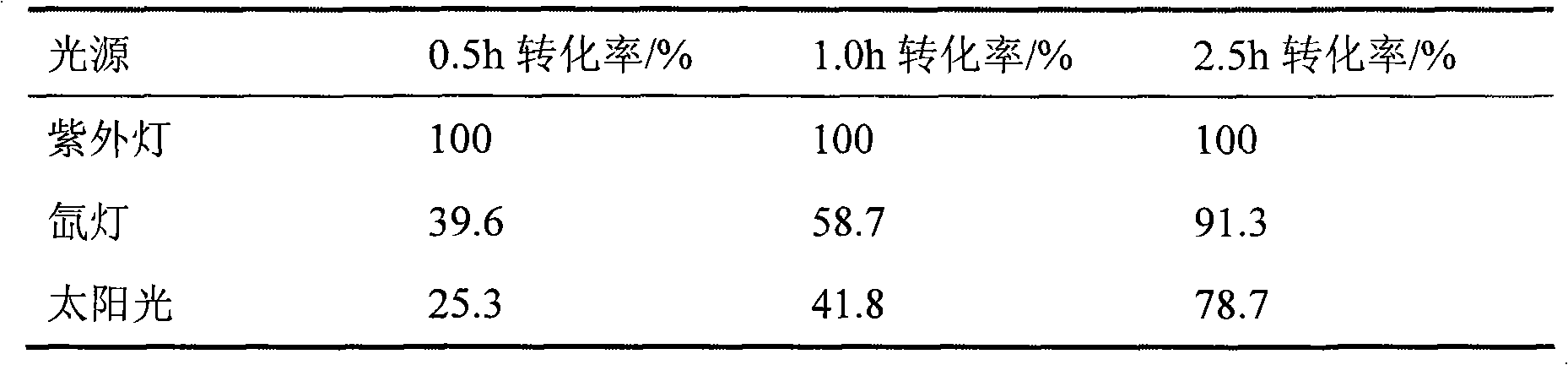

[0026] The obtained photocatalyst is used for oxidation treatment of methyl orange aqueous solution. The reaction conditions are: normal temperature and pressure, 50 mL of 10 mg / L methyl orange aqueous solution, 0.8 g / L of photocatalyst, and air is blown from the bottom of the reactor. Sample analysis was taken at regular intervals, and the conversion rate of methyl orange was measured by UV-Vis sp...

Embodiment approach 2

[0033] 1) Weigh 1 gram of analytically pure BiCl 3 placed in 0.1mol·L -1 Dilute hydrochloric acid 50mL, make BiCl 3 Fully dissolve and keep the solution in a transparent state;

[0034] 2) Add 0.1mol·L under magnetic stirring -1 urea solution 3mL and slowly drop Na 2 CO 3 solution, the pH value was controlled at 11, and the stirring reaction time was 1.2 hours;

[0035] 3) Filtrating the suspension solution obtained in step 2), washing the obtained solid phase product with distilled water, and then drying at a temperature of 50° C. to obtain the bismuth oxychloride photocatalyst.

[0036] The obtained photocatalyst is used for oxidation treatment of methyl orange aqueous solution. The reaction conditions are: normal temperature and pressure, 50 mL of 10 mg / L methyl orange aqueous solution, 1.5 g / L of photocatalyst, and air is blown from the bottom of the reactor. Samples were taken and analyzed at regular intervals, and the conversion rate of phenol was measured by UV-V...

Embodiment approach 3

[0040] 1) Weigh 1 gram of analytically pure BiCl 3 placed in 0.1mol·L -1 Dilute hydrochloric acid 50mL, make BiCl 3 Fully dissolve and keep the solution in a transparent state;

[0041] 2) Add 0.1mol·L under magnetic stirring -1 5mL of urea solution and slowly add Na 2 CO 3 solution, the pH value was controlled at 9, and the stirring reaction time was 1.1 hours;

[0042] 3) Filtrating the suspension solution obtained in step 2), washing the obtained solid phase product with distilled water, and then drying at 80° C. to obtain the bismuth oxychloride photocatalyst.

[0043] The obtained photocatalyst is used for oxidation treatment of methyl orange aqueous solution. The reaction conditions are: normal temperature and pressure, 50 mL of 10 mg / L methyl orange aqueous solution, 2.0 g / L of photocatalyst, and air is blown from the bottom of the reactor. Samples were taken and analyzed at regular intervals, and the conversion rate of humic acid was measured by UV-Vis spectrophot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com