Preparation method for visible-light-driven photocatalyst compositing bismuth oxychloride/silver carbonate

A technology of bismuth oxychloride and silver carbonate, applied in the field of photocatalysis, can solve the problems of reducing the photocatalytic activity of silver carbonate, and achieve the effects of easy control of preparation conditions, high catalytic efficiency and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

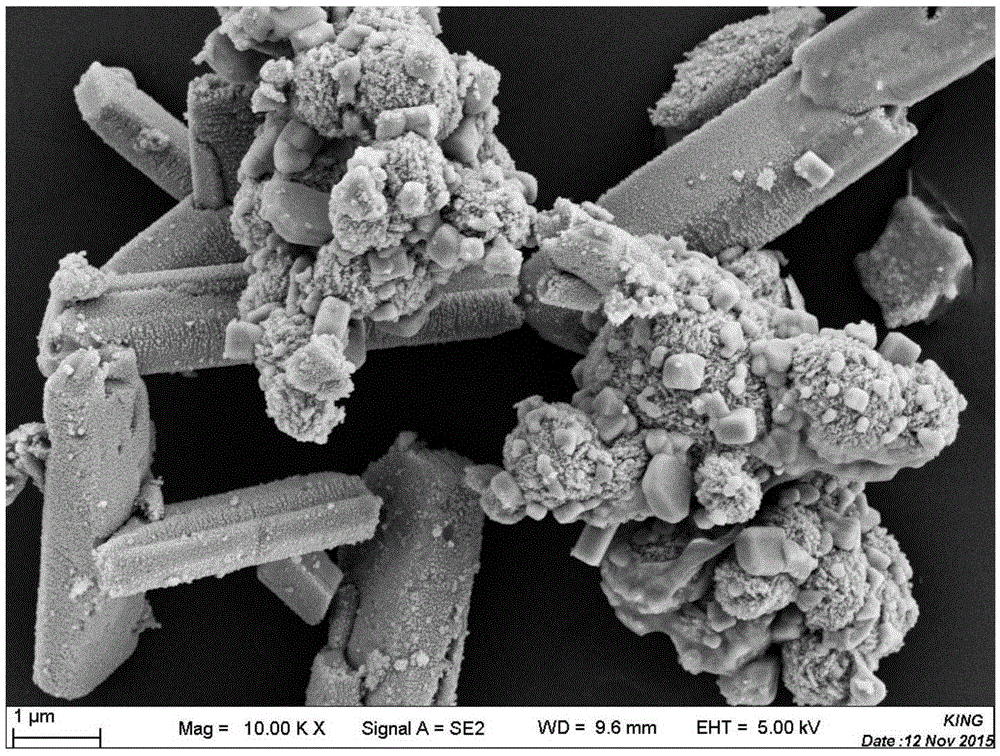

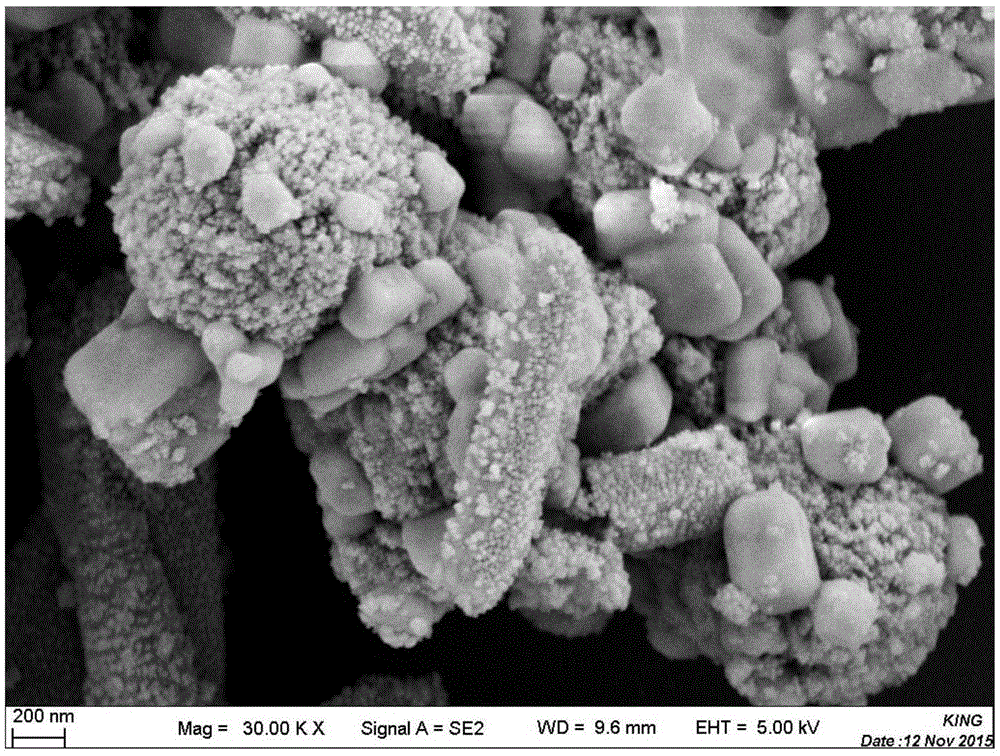

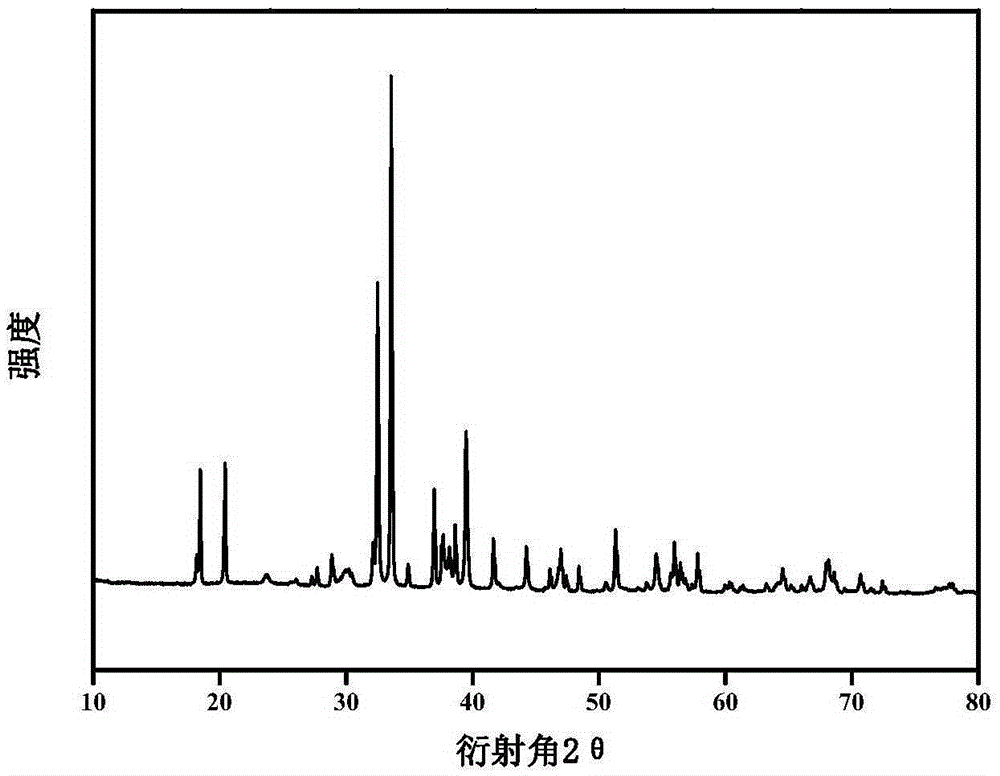

[0019] (1) Preparation of bismuth oxychloride: measure 20mL of ethylene glycol and add 1.1184g of bismuth nitrate, then measure 20mL of ethylene glycol and add 0.3728g of potassium chloride, mix the above two solutions and stir for 1h. Transfer the solution in the reaction vessel to a hydrothermal reaction kettle, react at 150°C for 10 hours, cool, filter, wash and dry;

[0020] (2) Preparation of bismuth oxychloride / silver carbonate composite photocatalyst: Add 17 mg of bismuth oxychloride to 50 mL of distilled water, stir ultrasonically for 1 h, add 0.85 g of silver nitrate, stir for 30 min, then add 50 mL of 0.05 mol / L bicarbonate dropwise Sodium solution, stirred for 24 hours, centrifuged, washed with ethanol and water successively, and dried to obtain the product.

Embodiment 2

[0022] (1) Preparation of bismuth oxychloride: measure 70mL of ethylene glycol and add 6.9520g of bismuth nitrate, then measure 70mL of ethylene glycol and add 1.3904g of potassium chloride, stir the above two solutions for 2h after mixing, and The solution in the reaction vessel was transferred to a hydrothermal reaction kettle, reacted at 180°C for 14 hours, cooled, filtered, washed and dried;

[0023] (2) Preparation of bismuth oxychloride / silver carbonate composite photocatalyst: Add 68 mg of bismuth oxychloride to 100 mL of distilled water, stir ultrasonically for 3 h, add 1.70 g of silver nitrate, stir for 50 min, then add 100 mL of 0.05 mol / L bicarbonate dropwise Sodium solution, stirred for 28 hours, centrifuged, washed with ethanol and water successively, and dried to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com