Technique for reclaiming smelting refined bismuth from bismuth slag

A technology for bismuth slag and refined bismuth is applied in the field of recycling and smelting refined bismuth, which can solve the problems of waste liquid discharge and pollution, and achieve the effects of reducing energy consumption, strong adaptability of raw materials, and stable production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

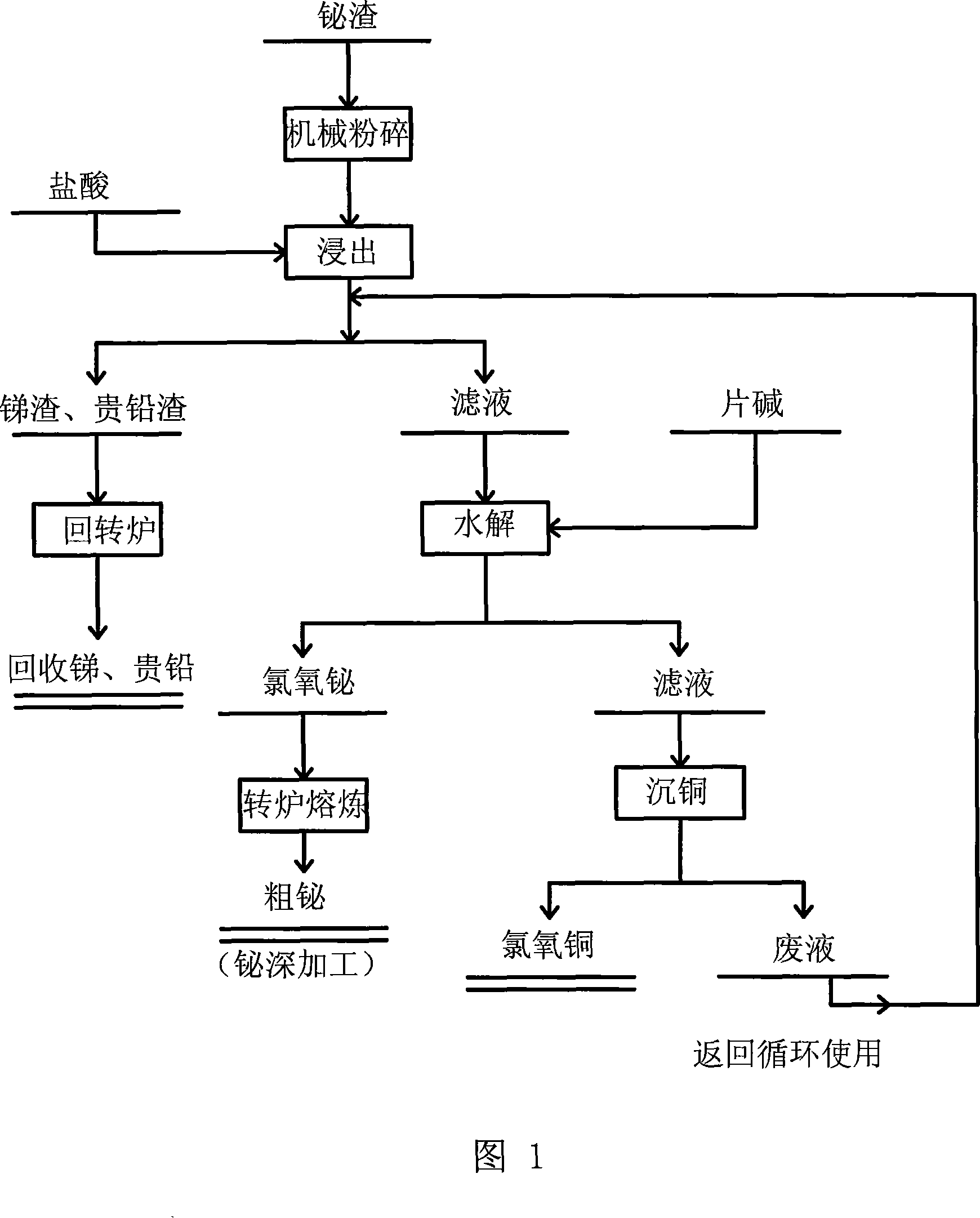

[0017] Below in conjunction with the production process flowchart of accompanying drawing, the present invention will be described in detail with specific embodiment:

[0018] Shown in the figure is a kind of technological step of recovering and smelting refined bismuth from bismuth slag as follows:

[0019] a. First mechanically crush the bismuth slag into a powder of more than 40 meshes, add hydrochloric acid to the powder bismuth slag according to the solid-liquid ratio of 3-6:1 for leaching and filtration, and control the leaching temperature at 75-90°C. 3 to 4 hours to obtain leach residue and leachate;

[0020] b. The leached slag produced is sent to the rotary furnace for smelting to recover antimony and precious lead;

[0021] c. The resulting leachate is hydrolyzed to precipitate bismuth, neutralized with caustic soda until the end point is PH=2 to 2.5, kept at a constant pH and stirred for 0.5 hours and then press-filtered to obtain bismuth oxychloride, which is sme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com