Gold-bismuth oxychloride nano composite material and preparation method thereof

A technology of bismuth oxychloride nano and composite materials, which is applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of small specific surface area of products, difficult surface modification of gold nanoparticles, energy consumption and time-consuming, etc. Achieve the effects of simple preparation method, controllable structural parameters and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The concrete steps of preparation are:

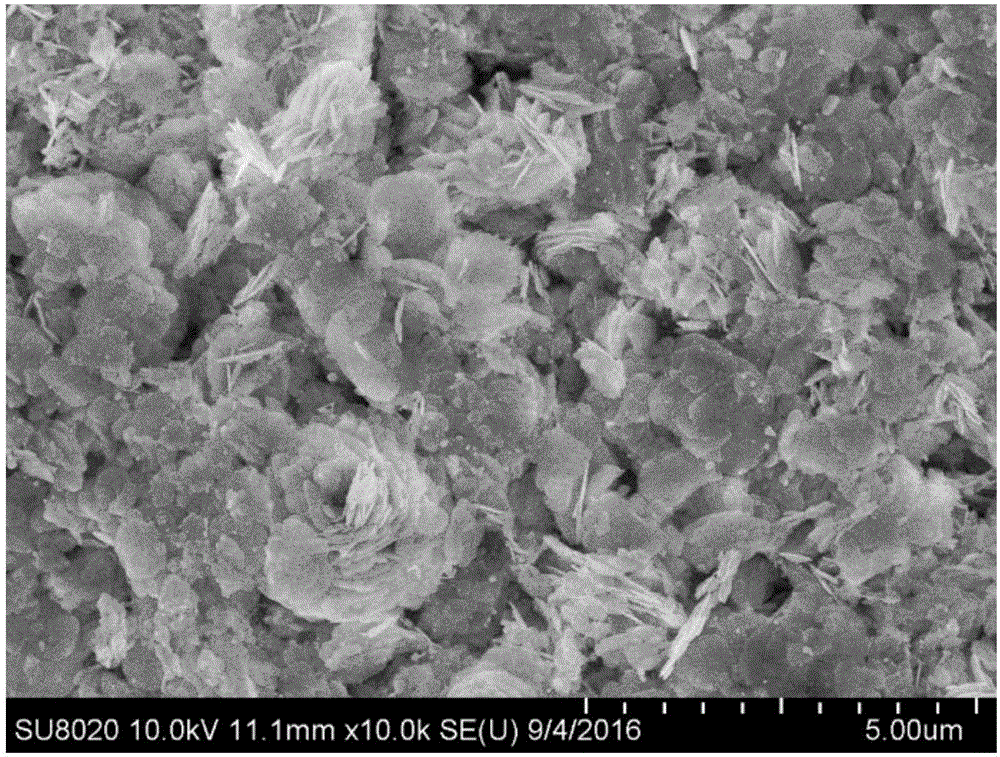

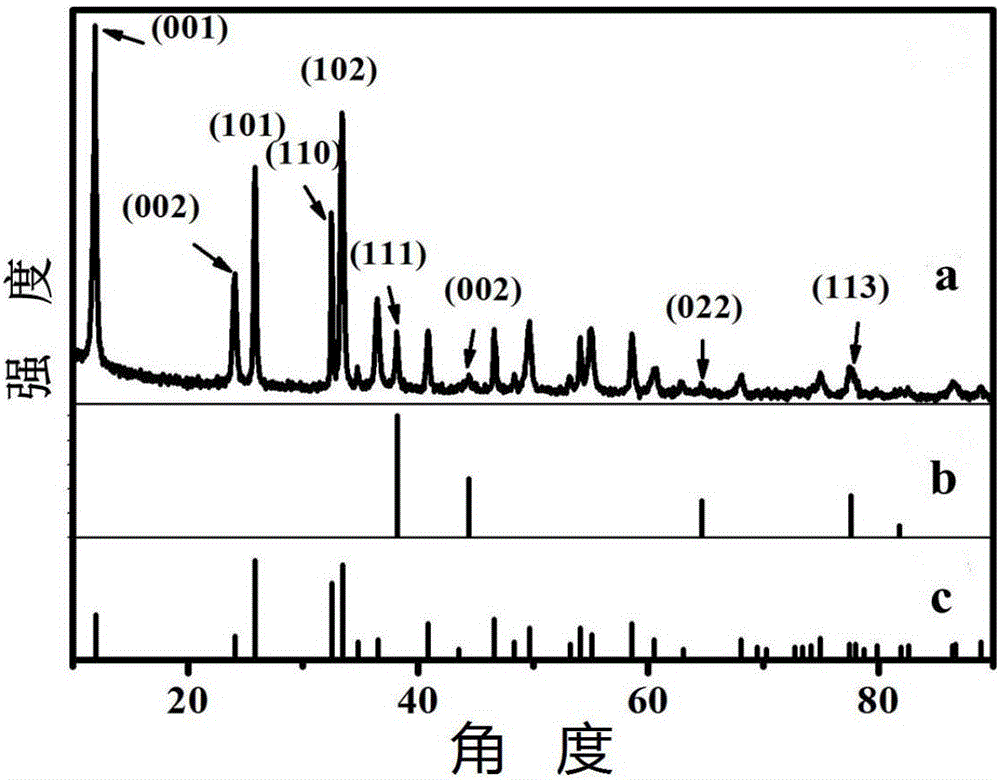

[0035] In step 1, the gold target is first placed in a stirred precursor solution, wherein the bismuth nitrate in the precursor solution is 0.08 mol / L, and the chloride content is 0.5 mol / L; the chloride is hydrogen chloride. Then use a laser with a wavelength of 532nm, a repetition rate of 1Hz, a pulse width of 15ns, and a power of 40mJ / pulse to irradiate the gold target for 30min; wherein, the laser with an emission wavelength of 532nm is a Nd:YAG solid-state laser, and the laser spot diameter is 0.5 mm to obtain a mixed colloid solution.

[0036] Step 2, the mixed colloidal solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation treatment is centrifugation, the rotation speed is 1000r / min, and the time is 20min, and the washing treatment is obtained by using deionized water to separate The solid matter is cleaned twice, the solid matter is separated by centrifugat...

Embodiment 2

[0038] The concrete steps of preparation are:

[0039] In step 1, the gold target is first placed in a stirred precursor solution, wherein the bismuth nitrate in the precursor solution is 0.09 mol / L, and the chloride content is 0.3 mol / L; the chloride is hydrogen chloride. Then use a laser with a wavelength of 532nm, a repetition rate of 5Hz, a pulse width of 13ns, and a power of 60mJ / pulse to irradiate the gold target for 28 minutes; the laser with an emission wavelength of 532nm is a Nd:YAG solid-state laser, and the laser spot diameter is 1mm , to obtain a mixed colloidal solution.

[0040] Step 2, the mixed colloidal solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotation speed is 3750r / min, and the time is 15min, and the washing process is obtained by using deionized water to separate The solid matter is cleaned twice, and the solid matter is separated by centrifugation...

Embodiment 3

[0042] The concrete steps of preparation are:

[0043] In step 1, the gold target is first placed in a stirred precursor solution, wherein the bismuth nitrate in the precursor solution is 0.1 mol / L, and the chloride content is 0.01 mol / L; the chloride is hydrogen chloride. Then use a laser with a wavelength of 532nm, a repetition rate of 10Hz, a pulse width of 10ns, and a power of 80mJ / pulse to irradiate the gold target for 25 minutes; wherein, the laser with an emission wavelength of 532nm is a Nd:YAG solid-state laser, and the laser spot diameter is 1.5 mm to obtain a mixed colloid solution.

[0044]Step 2, the mixed colloidal solution is subjected to solid-liquid separation, washing and drying in sequence; wherein, the solid-liquid separation process is centrifugation, the rotation speed is 6500r / min, and the time is 10min, and the washing process is obtained by using deionized water to separate The solid matter is cleaned twice, and the solid matter is separated by centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com