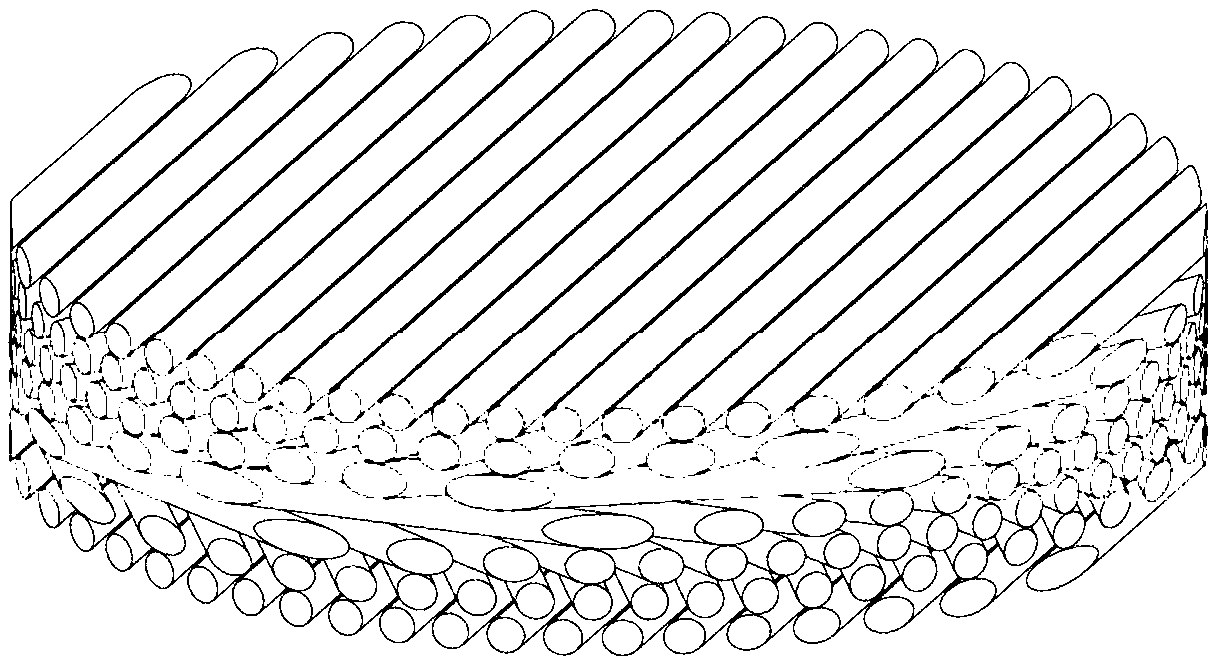

Preparation method of helically oriented nanofiber array

A nanofiber array and nanofiber technology, which is applied in fiber processing, filament/wire forming, textiles and papermaking, etc., can solve the problems of low efficiency and complex preparation methods of nanofiber arrays, and achieve simple equipment, high-efficiency preparation, and simplified The effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) At room temperature, mix dimethylformamide (DMF) and tetrahydrofuran (THF) at a mass ratio of 1:1 as a solvent, and then add polyurethane (PU) particles into the solvent to make the mass fraction 20%-30% , and then stirred with an electromagnetic stirrer for 2 hours to obtain a spinning solution;

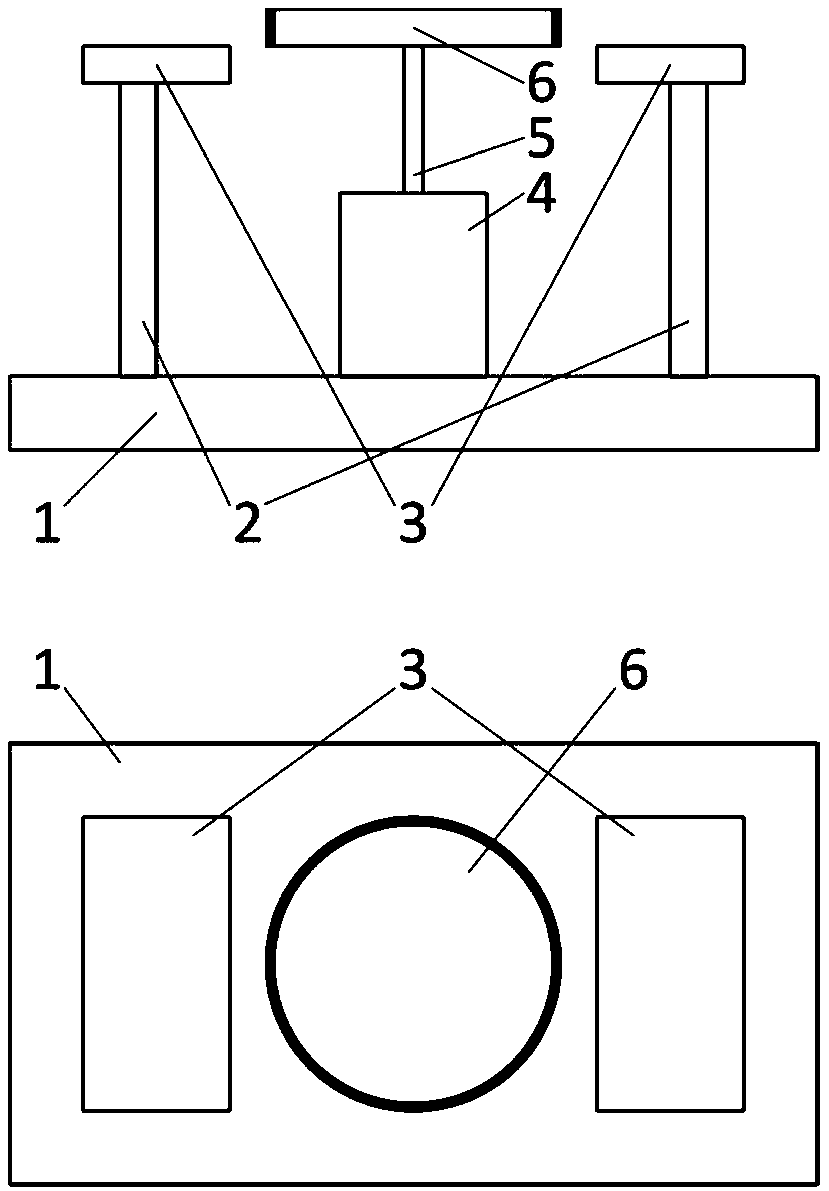

[0034] (2) Ground the two electrodes, connect the rear end of the spinning nozzle to the injection pump through a catheter, connect the conductive part of the spinning nozzle to the high-voltage DC power supply 7, and adjust the high-voltage DC power supply to about 10-12KV;

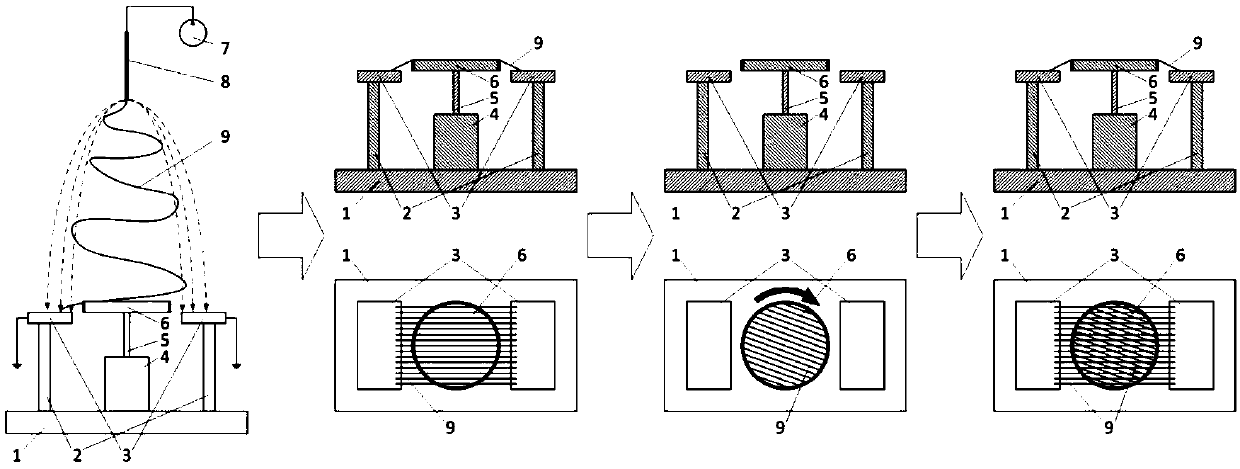

[0035] (3) Adjust the syringe pump to feed the spinning solution at a speed of 0.2-0.8ml / h. The solution is charged at the spinning nozzle and moves to the other electrode along the electric field line. At the same time, the solvent continues to volatilize in the air, causing the solute Cured to obtain charged nanofibers. When the nanofiber moves to the electrode, the electrode in contact with the ...

Embodiment 2

[0039] (1) At room temperature, mix dimethylformamide (DMF) and tetrahydrofuran (THF) at a mass ratio of 1:1 as a solvent, and then add polylactic-co-glycolic acid (PLGA) particles into the solvent to make the mass fraction 20%-30%, then stirred with an electromagnetic stirrer for 2 hours to obtain a spinning solution;

[0040](2) Ground the two electrodes, connect the rear end of the spinning nozzle to the injection pump through a catheter, connect the conductive part of the spinning nozzle to the high-voltage DC power supply 7, and adjust the high-voltage DC power supply to about 10-12KV;

[0041] (3) Adjust the syringe pump to feed the spinning solution at a speed of 0.2-0.8ml / h. The solution is charged at the spinning nozzle and moves to the other electrode along the electric field line. At the same time, the solvent continues to volatilize in the air, causing the solute Cured to obtain charged nanofibers. When the nanofiber moves to the electrode, the electrode in contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com