Bowl-shaped metallic nanostructures

A metal nanostructure and bowl-shaped technology, which is applied in nanotechnology, nano-optics, nanotechnology, etc., can solve the problems affecting the application range of the ball-bowl, the structural parameters are not easy to control, and it is not integrally formed. It is easy to industrialize production and realize The effect of industrialized production and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The bowl-shaped metal nanostructure provided by the present invention, its preparation method, and the detection system using the bowl-shaped metal nanostructure will be further described in detail below in conjunction with the accompanying drawings and specific examples.

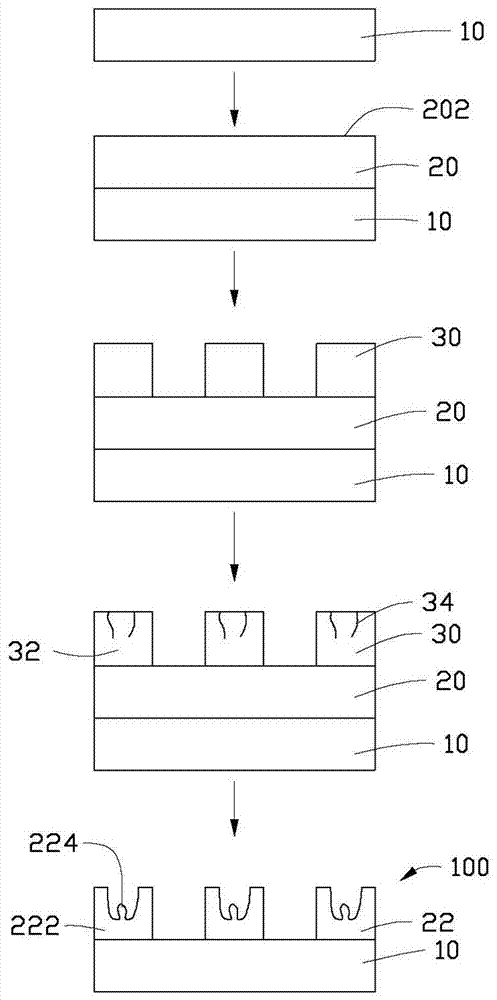

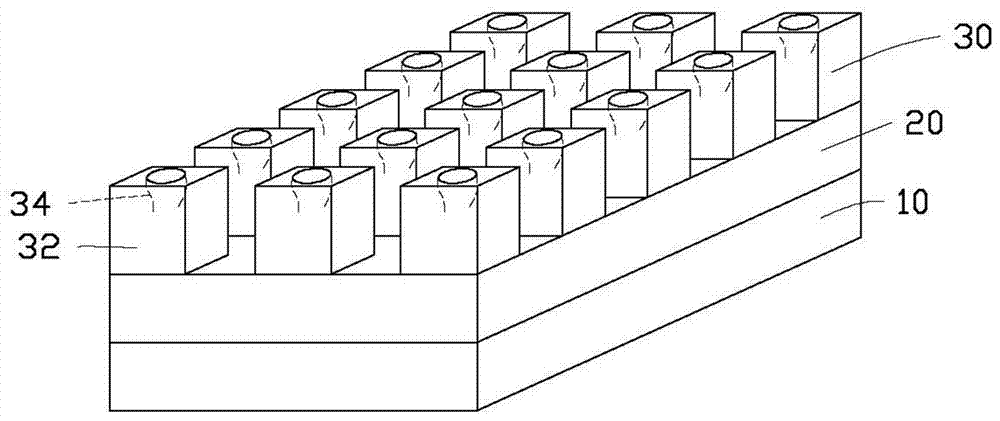

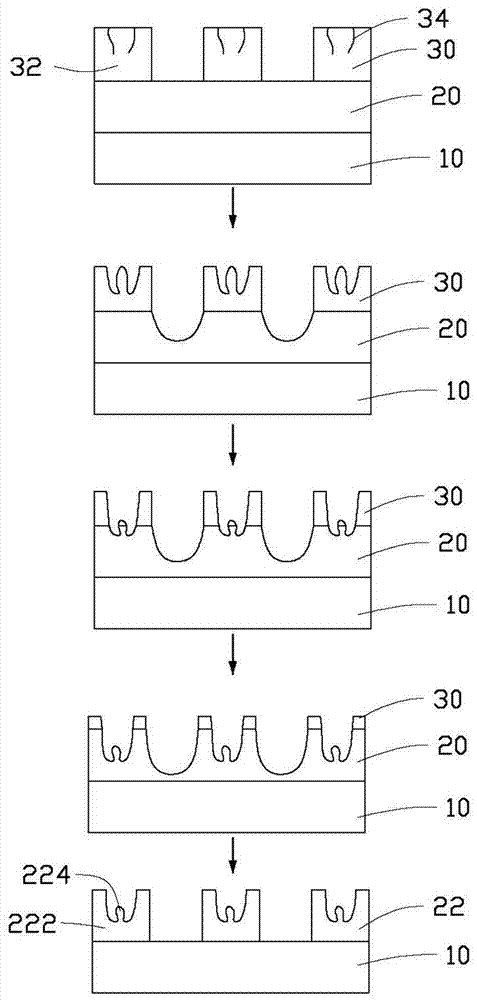

[0025] Please also see figure 1 and figure 2 , the present invention provides a method for preparing a bowl-shaped metal nanostructure array 100, which includes the following steps:

[0026] Step S1, providing a substrate 10;

[0027] Step S2, disposing a metal layer 20 on the surface of the substrate 10, the metal layer 20 has a first surface 202, and the first surface 202 is far away from the substrate 10;

[0028] Step S3, setting a patterned mask layer 30 on the first surface 202 of the metal layer 20, the patterned mask layer 30 covers a part of the first surface 202 of the metal layer 20, and exposes the the rest of the first surface 202 of the metal layer 20;

[0029] Step S4, annealing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com