Preparation method of sheet-like bismuth oxychloride photocatalyst

A bismuth oxychloride catalyst, sheet-like technology, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., to achieve the effects of novel structure, high photocatalytic activity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

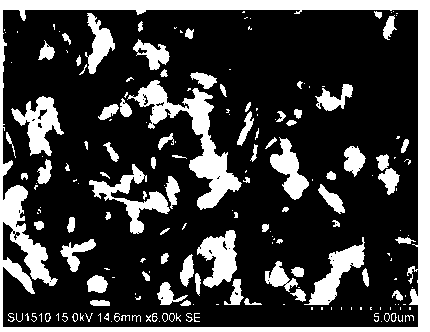

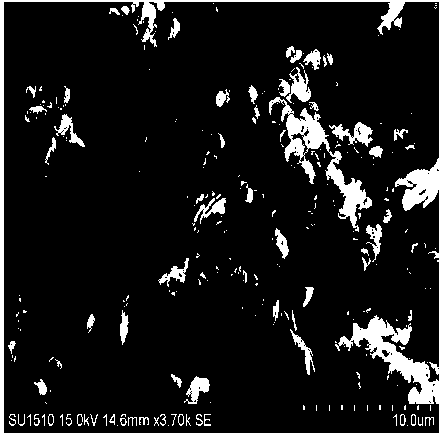

Image

Examples

Embodiment 1

[0031] Embodiment one: (The weight ratio of distilled water to cetyltrimethylammonium bromide is 83:1, and the molar ratio of cetyltrimethylammonium bromide, bismuth nitrate pentahydrate, and sodium chloride is 1:15: 7)

[0032] Take 0.36g CTAB (cetyltrimethylammonium bromide) in 30mL water, stir to dissolve, then add 0.73g bismuth nitrate pentahydrate, finally add 0.43g sodium chloride, stir for 10min, pour into the tetrafluoroethylene lining , put it into an oven at 180°C, after 24 hours, centrifuge to wash the precipitate, and then dry it at 60°C.

Embodiment 2

[0033] Embodiment two: (The weight ratio of distilled water to cetyltrimethylammonium bromide is 83:1, and the molar ratio of cetyltrimethylammonium bromide, bismuth nitrate pentahydrate, and sodium chloride is 0.5:15: 7)

[0034] Take 0.18g CTAB (cetyltrimethylammonium bromide) in 30mL water, stir to dissolve, then add 0.73g bismuth nitrate pentahydrate, finally add 0.43g sodium chloride, stir for 10min, pour into the tetrafluoroethylene lining , put it into an oven at 180°C, after 24 hours, centrifuge to wash the precipitate, and then dry it at 60°C.

Embodiment 3

[0035] Embodiment three: (The weight ratio of distilled water to cetyltrimethylammonium bromide is 83:1, and the molar ratio of cetyltrimethylammonium bromide, bismuth nitrate pentahydrate, and sodium chloride is 1:15: 10)

[0036] Take 0.36g CTAB (cetyltrimethylammonium bromide) in 30mL water, stir to dissolve, then add 0.73g bismuth nitrate pentahydrate, finally add 0.58g sodium chloride, stir for 10min, pour into the tetrafluoroethylene lining , put it into an oven at 180°C, after 24 hours, centrifuge to wash the precipitate, and then dry it at 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com