Prussian blue pearlescent pigment and preparation method thereof

A technology of Prussian blue and effect pigments, applied in inorganic pigment processing, chemical instruments and methods, pharmaceutical formulations, etc., can solve problems such as coatings without disclosed pearlescent particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0009] The preparation method of Prussian blue series pearlescent pigment of the present invention comprises:

[0010] The transparent or translucent inorganic sheet-like material used as the substrate and water are mixed and stirred in a reactor at a solid-to-liquid ratio of 1:4-8, and the temperature is raised to 60-95°C, preferably 78-88°C, to obtain a suspension; A certain concentration of ferric chloride (FeCl 3 ), ferric nitrate (Fe(NO 3 ) 3 ) and iron sulfate (Fe 3 (SO 4 ) 2 ) in the iron salt solution from the top of the suspension in the reactor and above or below the liquid level, while adding a certain concentration of potassium ferrocyanide K 4 Fe(CN) 6 The solution is added from the bottom of the suspension (ie close to the bottom of the reactor), and at the same time a NaOH solution with a concentration of 1%-10% (mass percentage) is added to maintain the pH of the entire reaction system=3-5. After the reaction is completed by visual inspection, filter, wa...

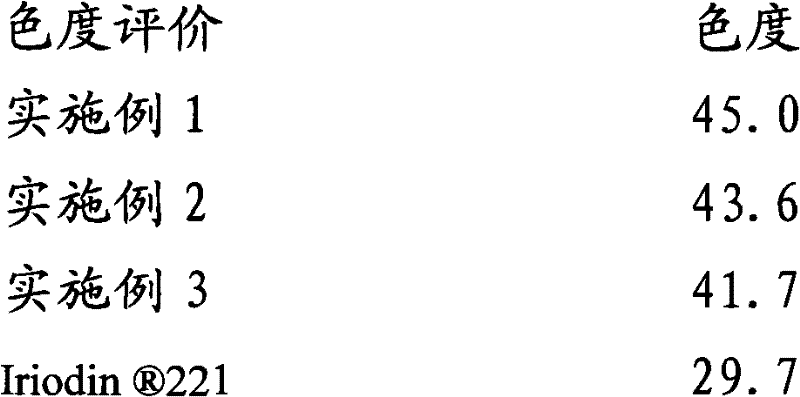

Embodiment 1

[0033] In the reactor, 200 grams of natural mica-coated TiO with an average particle size of 20um 2 The interference blue pearlescent pigment (KC225) was used as a coating substrate, and 800 grams of water was added for stirring (-400rpm / min), and the temperature was raised to 85°C to obtain a suspension. 38% concentration (w / w) FeCl 3 The solution is added from above the suspension and below the liquid level at a speed of 7.5ml / min, and at the same time the concentration of 29% K 4 Fe(CN) 6 The solution was added from below the suspension (the bottom of the suspension, ie near the bottom of the reactor) at a rate of 0.5 ml / min, and the pH of the system was maintained at 3.3 with 10% NaOH solution, and the reaction was stirred while feeding. When the reaction was carried out to 120 minutes, the reaction was stopped (judged by measuring the color value with a color difference meter), and the above-mentioned system appeared dark blue. After the above system is filtered, washe...

Embodiment 2

[0035] Repeat embodiment 1, just be 30um natural mica coating Fe with 200 grams of mean particle size 2 o 3 The golden pearlescent pigment (KC300) is used as the coating substrate, and the reaction time is 80 minutes to obtain the green pearlescent effect pigment. The average thickness of the Prussian blue coating is 30 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com