Cobalt oxide doped basic bismuth carbonate/bismuth oxychloride photocatalyst and preparation method thereof

A technology of bismuth oxychloride and photocatalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., which can solve the limitation of large-scale production and application, which affects photocatalyst Large-scale production, cumbersome and complicated hydrothermal synthesis methods, etc., to achieve the effect of inhibiting recombination, increasing absorption, and accelerating transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of cobalt oxide-doped bismuth subcarbonate / bismuth oxychloride photocatalyst preparation method of the present invention, the concrete steps of this method are as follows:

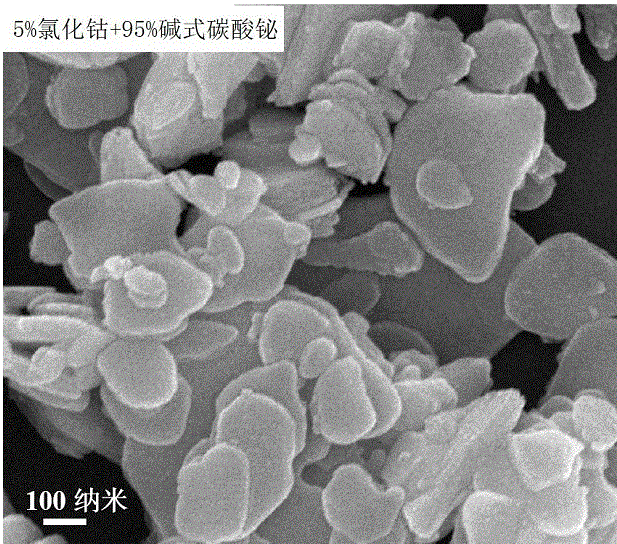

[0027] Weigh 0.05 g of cobalt chloride (BiOCl) dissolved in 10 mL of deionized water, then weigh 1.0 g of bismuth subcarbonate Bi 2 o 2 CO 3 Add to the above solution, ultrasonically disperse for 30 minutes; heat and stir at 100°C until the water evaporates completely, grind into powder, and then heat up to 350°C at a rate of 5°C / min and calcinate for 3 hours, and cobalt oxide can be obtained after calcining Doped bismuth subcarbonate / bismuth oxychloride photocatalysts, such as figure 1 As shown, the specification model of the described bismuth subcarbonate is CAS 5892-10-4 (produced by Aladdin Biochemical Technology Co., Ltd.); the specification model of cobalt chloride is CAS 7791-13-1 (produced by Aladdin Biochemical Technology Co., Ltd. Co., Ltd.).

Embodiment 2

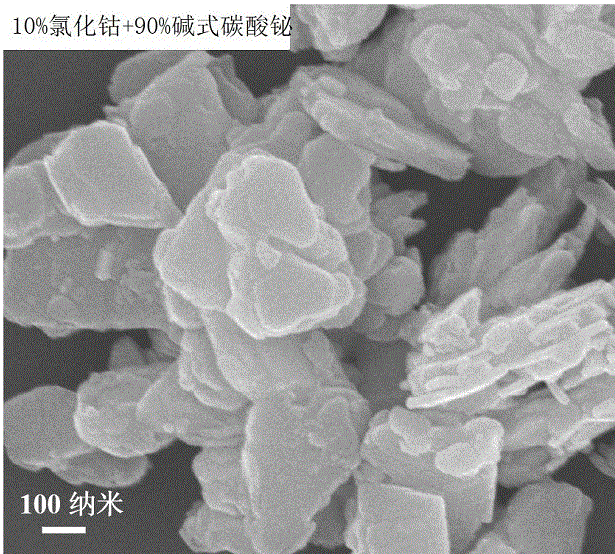

[0029] This Example 2 is basically the same as Example 1, except that the cobalt chloride weighed 0.1 g described in the above step (1) is added to 10 mL deionized water to obtain cobalt oxide doped basic carbonate Bismuth / bismuth oxychloride photocatalysts, such as figure 2 shown

Embodiment 3

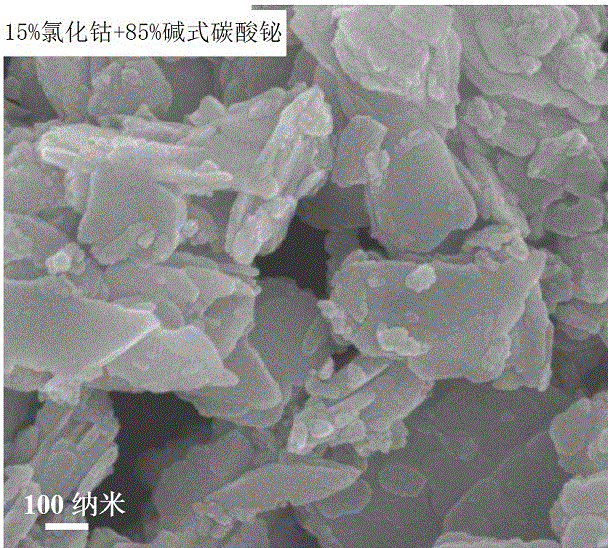

[0031] The present embodiment 3 is basically the same as the embodiment 1, except that the cobalt chloride weighing 0.15 g described in the above step (1) is added to 10 mL deionized water to obtain the cobalt oxide-doped basic carbonate Bismuth / bismuth oxychloride photocatalysts, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com