Wet process for lead-silver residues

A technology of wet treatment and lead-silver slag, applied in the direction of improving process efficiency, etc., can solve problems such as low metal direct recovery rate, environmental secondary pollution, equipment corrosion, etc., and achieve high silver direct recovery rate and high comprehensive recovery degree , the effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

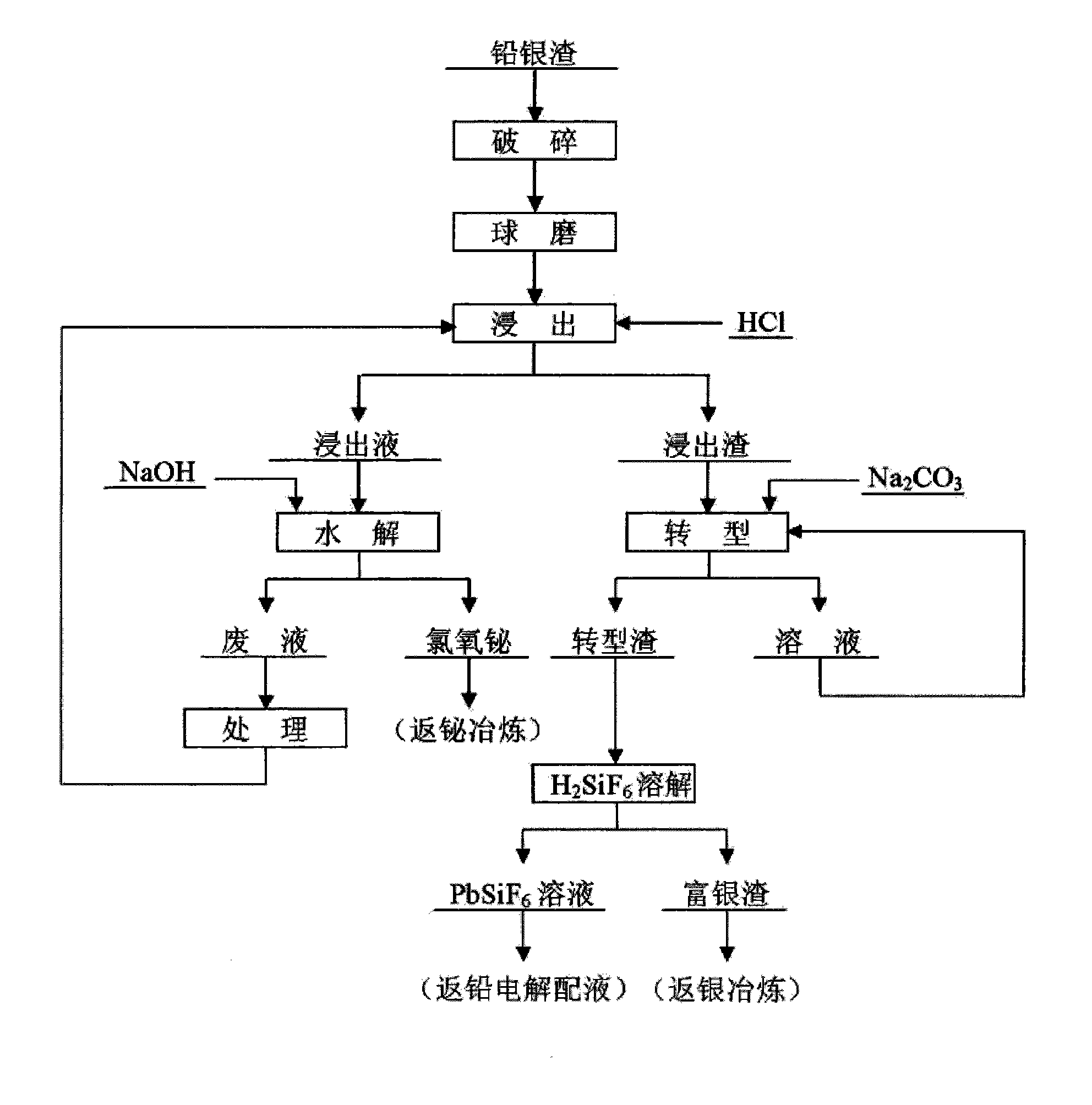

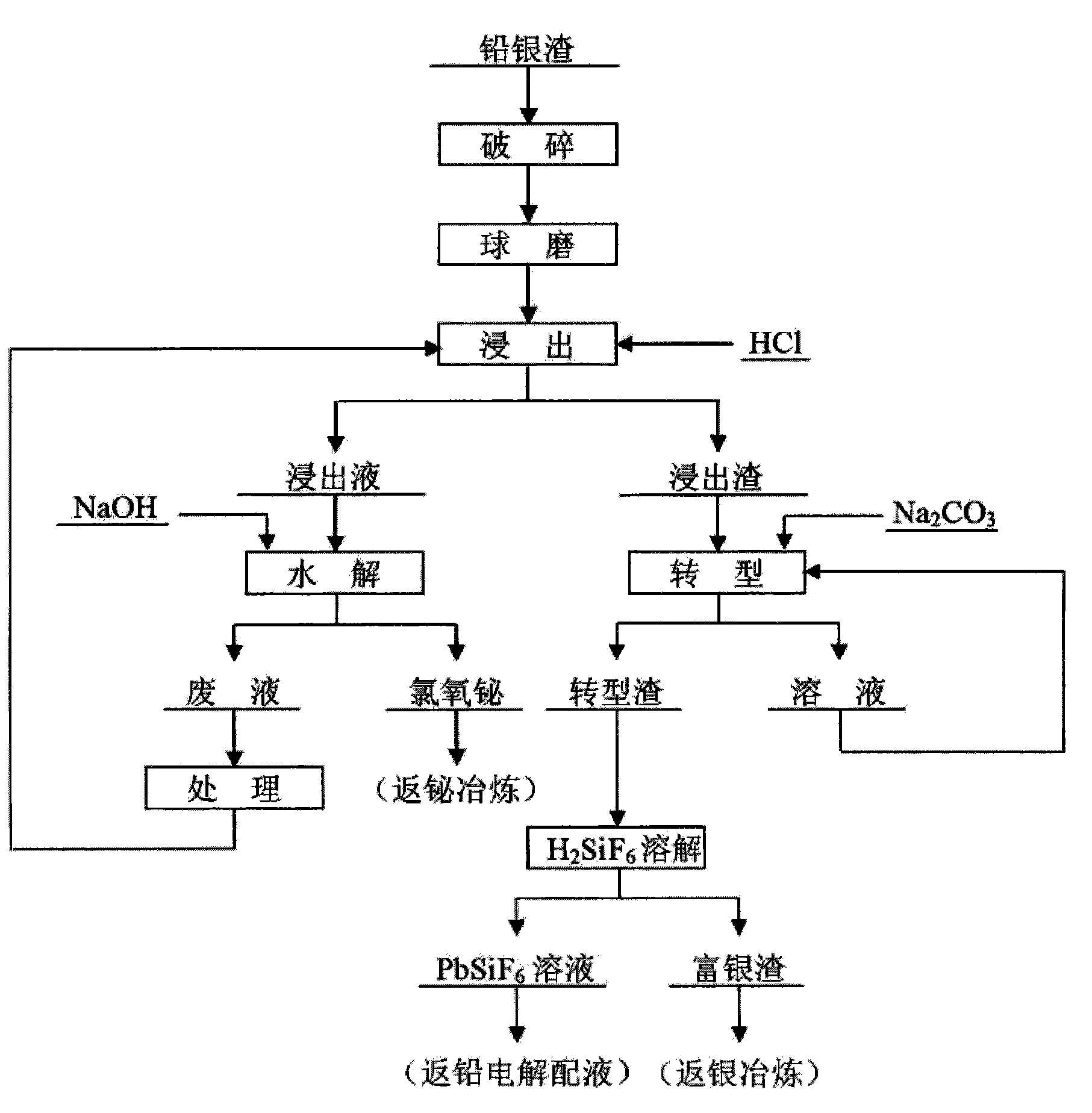

Method used

Image

Examples

Embodiment 1

[0019] A kind of lead-silver slag wet treatment process is to carry out according to the following steps:

[0020] a Take 5L industrial grade concentrated hydrochloric acid and dissolve it in 300L water to make dilute hydrochloric acid; -1 , Bi 2% lead-silver slag crushed, ball milled to a particle size below 0.15mm, 100kg was leached with the above-mentioned dilute hydrochloric acid solution, and filtered; -1 After stirring for 90min, filter to obtain lead containing 71.4%, silver Ag18447g t -1 , Bismuth 0.09% leaching residue 85kg;

[0021] b) The obtained leaching liquid in step a is heated to 90° C. while stirring, adding industrial grade sodium hydroxide, adjusting the pH to about 1.5, continuing to stir for 30 minutes and then filtering to obtain bismuth oxychloride. The hydrolyzed liquid is treated and returned to step a for leaching and utilization;

[0022] c takes by weighing 93kg technical grade sodium carbonate and is dissolved in 255L water, is heated up to 85 ℃...

Embodiment 2

[0024] A kind of lead-silver slag wet treatment process is to carry out according to the following steps:

[0025] a Take 15L industrial grade concentrated hydrochloric acid and dissolve it in 900L water to make dilute hydrochloric acid; -1 , Bi 3% lead-silver slag crushed, ball milled to a particle size below 0.15mm, take 300kg and leaching with the above-mentioned dilute hydrochloric acid solution, and filter; -1 After stirring for 90min, filter to obtain lead containing 65.3%, silver Ag7594g t -1 , bismuth 0.09% leaching residue 270kg;

[0026] b) The obtained leaching solution in step a is heated to 80°C while stirring, adding industrial grade sodium hydroxide, adjusting the pH to about 2.5, continuing to stir for 30 minutes and then filtering to obtain bismuth oxychloride; the hydrolyzed solution is returned to step a for leaching and utilization;

[0027] c takes by weighing 270kg industrial grade sodium carbonate and dissolves it in 810L water, heats up to 80 ℃, adds ...

Embodiment 3

[0029] A kind of lead-silver slag wet treatment process is to carry out according to the following steps:

[0030] a Take 15L industrial grade concentrated hydrochloric acid and dissolve it in 900L water to make dilute hydrochloric acid; -1 , Bi 5% lead-silver slag crushed, ball milled to a particle size below 0.15mm, take 300kg and leaching with the above-mentioned dilute hydrochloric acid solution, and filter; -1 After stirring for 30min, filter, at room temperature with 300r min -1 After stirring for 90min, filter to obtain lead containing 62.2%, silver Ag8894g t -1 , bismuth 0.07% leach residue 263kg;

[0031] b) The temperature of the obtained leaching solution in step a is raised to 50°C while stirring, adding industrial grade sodium hydroxide, adjusting the pH to about 2, continuing to stir for 30 min, and then filtering to obtain bismuth oxychloride. ;

[0032] c takes by weighing 270kg technical grade sodium carbonate and dissolves it in 810L water, is warming up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com