Chloride ion battery

A chloride ion, battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of poor safety and high price of metal lithium, and achieve the effect of low price and large reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

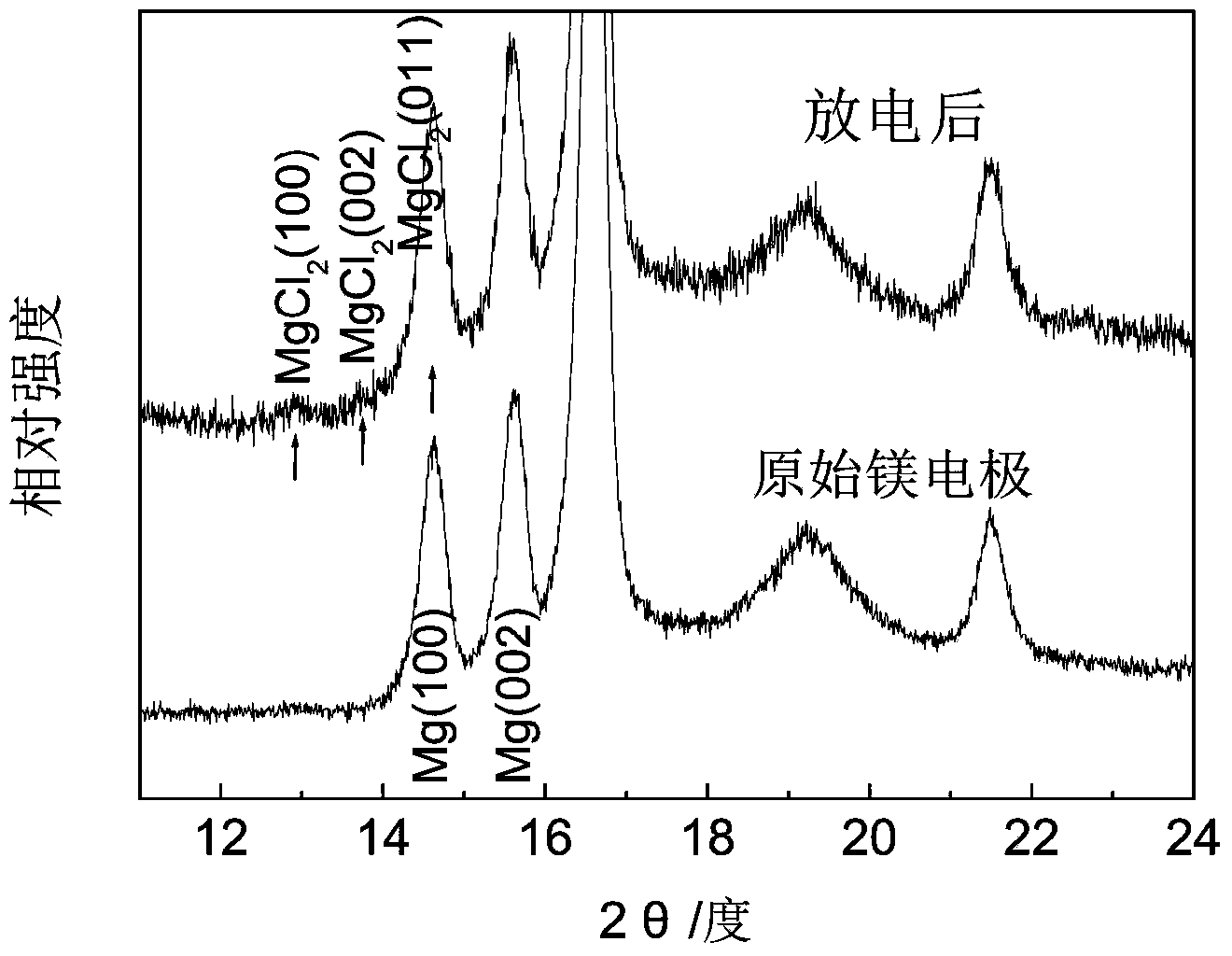

[0031] 1), battery assembly: put commercially available magnesium powder (99.6%, Alfa Aesar) and 20% by weight of carbon black into a sealed ball mill jar protected by argon, and ball mill for 20 hours at a speed of 200 rpm. The ratio was 10:1, and the Mg / C composite material (M1) was prepared, and then 14 mg of the powder was weighed and cold-pressed into a thin sheet with a diameter of 11 mm and a thickness of about 0.1 mm, as a negative electrode. at 0.6M PP 14 Cl / PP 14 The TFSI mixed ionic liquid is used as the electrolyte, and the BiOCl / C (10% carbon content) composite material is used as the positive electrode material.

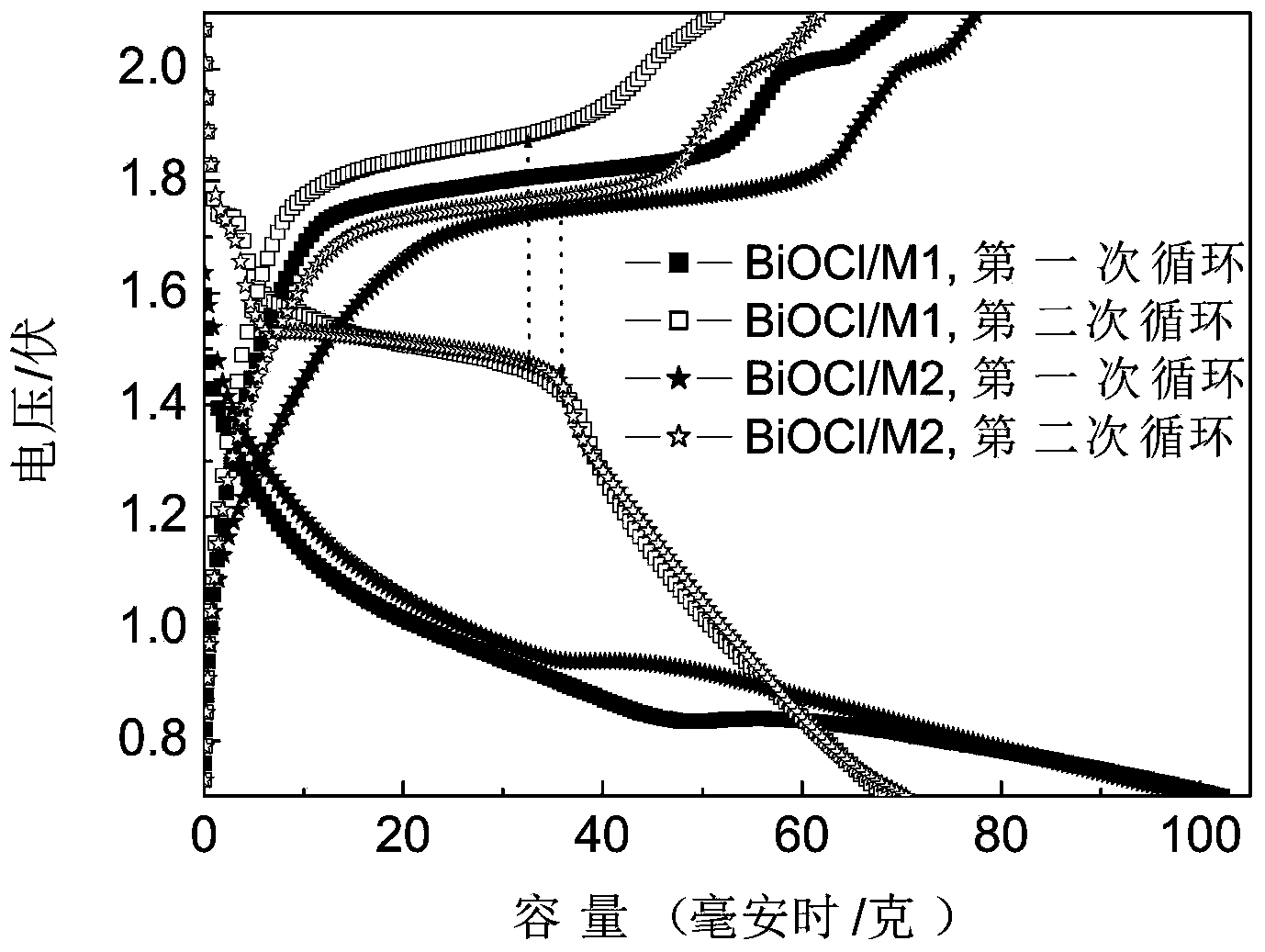

[0032] 2), the results of charge and discharge experiments show that (such as figure 1 As shown), the first discharge capacity of the BiOCl positive electrode material is 102mAh / g, reaching 99% of the theoretical capacity, the subsequent charge capacity is 68%, and the Coulombic efficiency is 68%. After the first activation, the battery discharge pla...

Embodiment 2

[0034] 1), battery assembly: put commercially available magnesium hydride powder and carbon black into a sealed ball mill tank protected by argon, and ball mill for 50 hours at a speed of 200 rpm with a ball-to-material ratio of 40:1 to obtain MgH 2 / C composite material, and then under vacuum conditions, the Mg / C composite material (M2, carbon content 40%) was obtained through 400 ° C for 12 hours. Weighed 14 mg of the powder and cold-pressed it into a diameter of 11 mm and a thickness of about 0.1 mm. slices as the negative electrode. at 0.5MPP 14 Cl / PP 14 The TFSI mixed ionic liquid is the electrolyte, and the BiOCl / C (40% carbon content) composite material is used as the positive electrode material.

[0035] 2), the results of charge and discharge experiments show that (such as figure 1 As shown), the Mg / C composite material (M2) prepared by the thermal decomposition method can effectively improve the charge-discharge Coulombic efficiency of the BiOCl positive electrode...

Embodiment 3

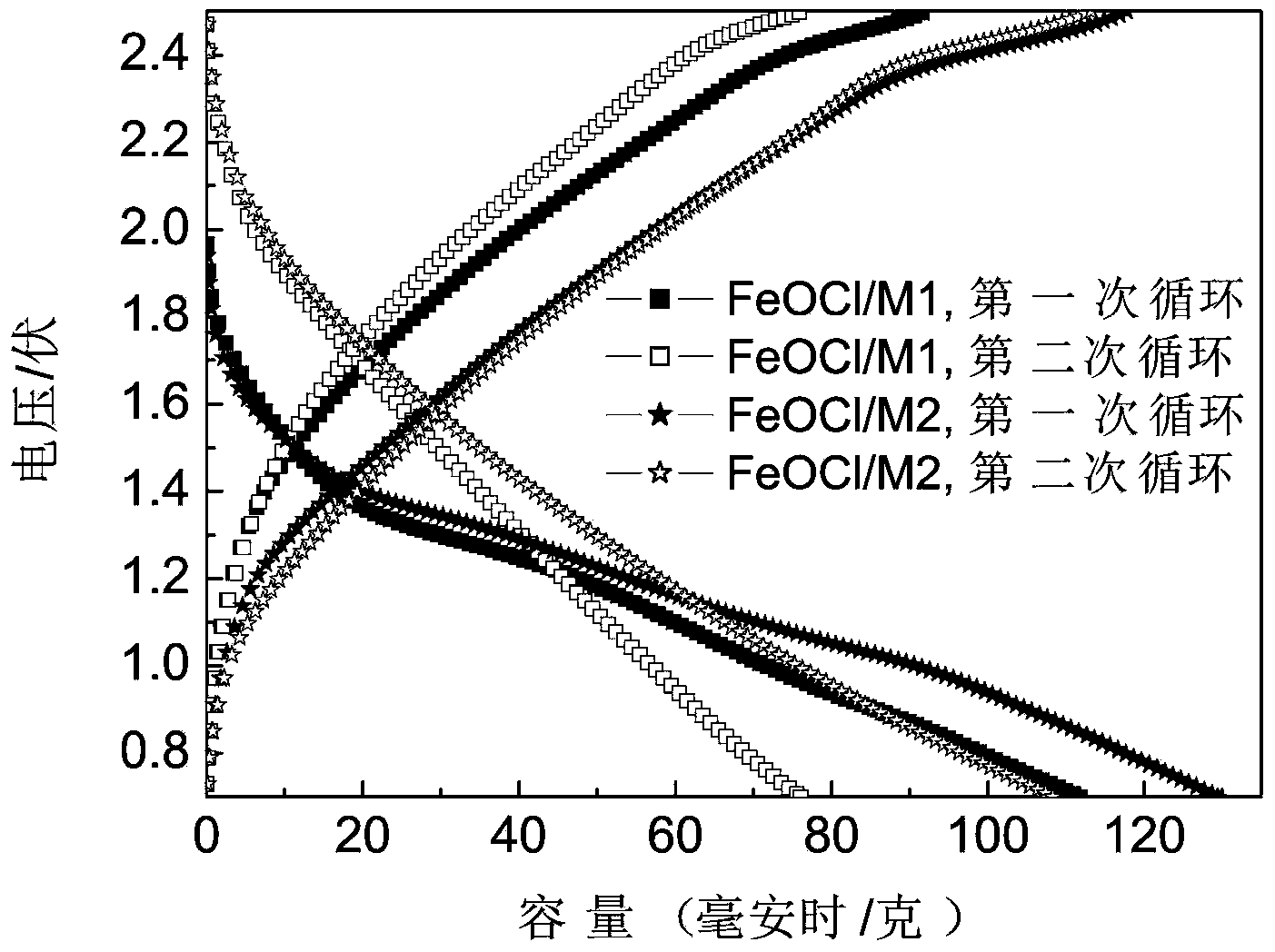

[0037] 1), battery assembly: put commercially available magnesium powder (99.6%, Alfa Aesar) and graphene of 5% by weight into an argon-protected sealed ball mill tank, and ball mill it for 10 hours at a speed of 250 rpm. The ratio is 20:1, and the Mg / C composite material (M1) is obtained; or the commercially available magnesium hydride powder (98%, Alfa Aesar) and graphene are packed in the sealed ball mill jar of argon protection, at 500 rpm Ball milling for 25 hours at a rotating speed of 40:1 to obtain MgH 2 / C composite material, and then under vacuum conditions, the Mg / C composite material (M2, containing 20% carbon) was obtained by heat preservation at 330° C. for 28 hours. Weighed 14 mg of the powder and cold-pressed it into a thin sheet with a diameter of 11 mm and a thickness of about 0.1 mm, which was used as a negative electrode. at 0.5M PP 14 Cl / PP 14 The TFSI mixed ionic liquid is the electrolyte, and the FeOCl / C (containing 25% carbon) composite material is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com