Preparation method and application of high-efficiency ultraviolet visible full-spectrum photocatalytic material

A technology of photocatalytic materials and catalytic materials, applied in the field of environmental functional materials, can solve problems such as low energy utilization rate and photocatalytic efficiency, difficulty in realizing industrial production, and long preparation cycle, and achieve low production cost, easy long-term storage, good Effect of photocatalytic degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

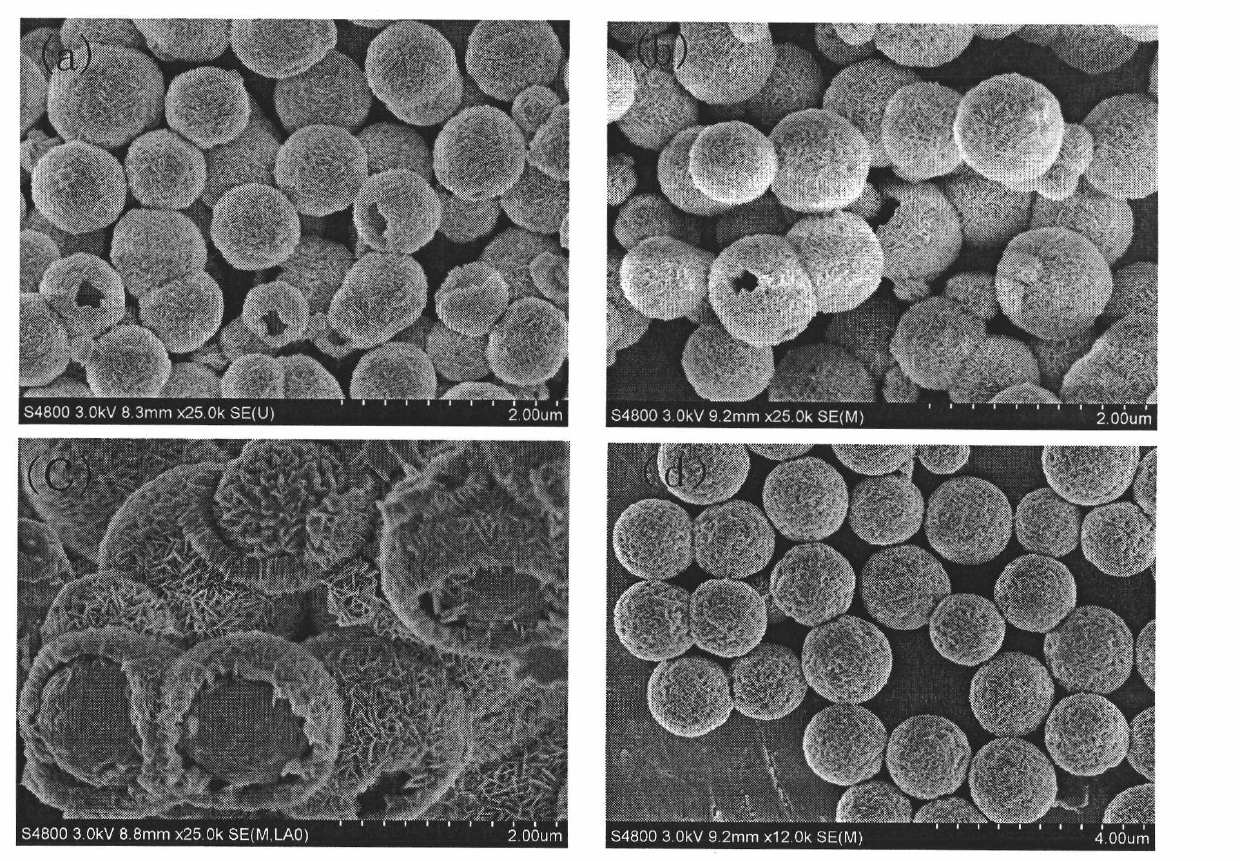

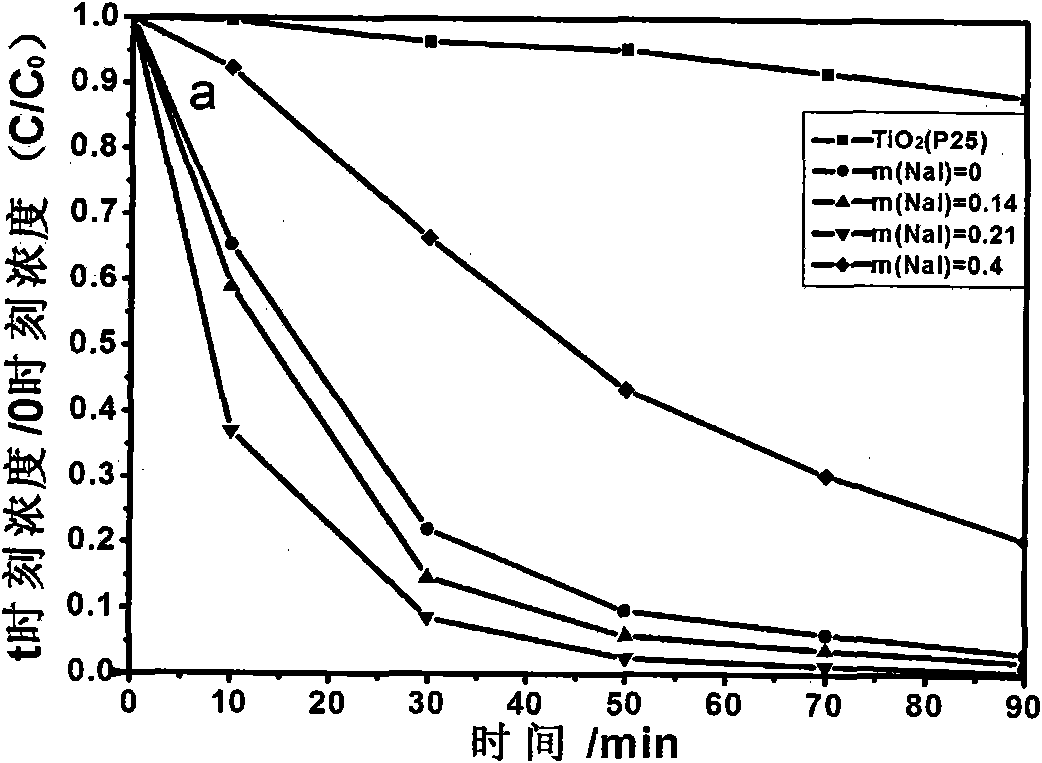

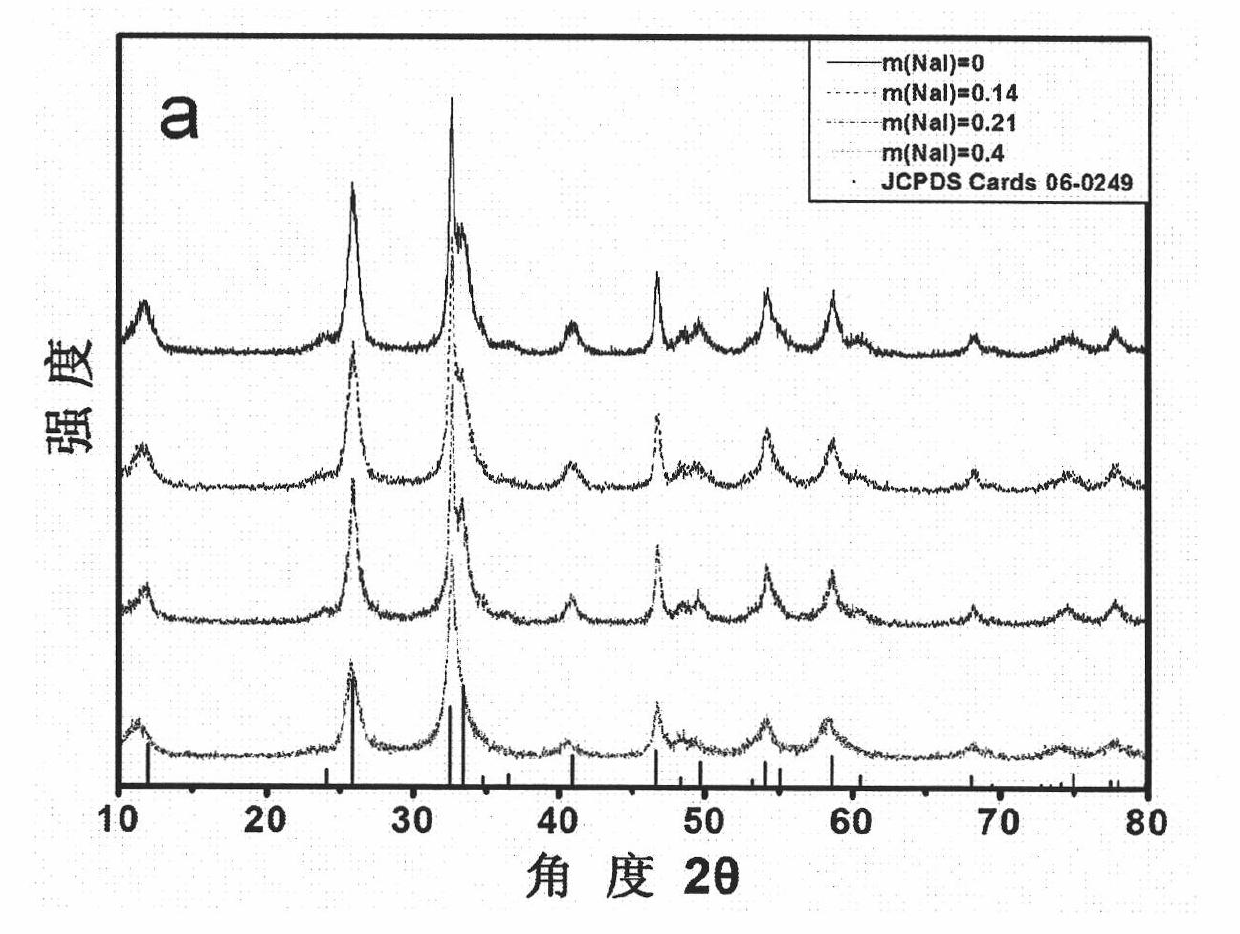

[0028] The preparation process of the present embodiment, concrete steps are as follows:

[0029] a) Take 200 parts of distilled water, add 0.5 part of citric acid, 0.01 part of polyvinylpyrrolidone, and 0 part of sodium iodide respectively, and stir to dissolve it;

[0030] b) Heat the above mixed solution to 60°C in the heating mantle, slowly add 3 parts of bismuth chloride to it after it is stable, continue to stir at 60°C for 3 hours, wait for it to cool down at a speed of 8000r / min Centrifuge for 4 minutes;

[0031] c) placing the centrifuged product in step b in a vacuum drying oven at 60° C. for 4 hours;

[0032] d) Place the cooled product in an agate mortar and grind for 5 minutes.

Embodiment 2

[0034] The preparation method of this embodiment is the same as that described in Example 1, except that in step a) 200 parts of distilled water are taken, 0.5 part of citric acid is added thereto, 0.01 part of polyvinylpyrrolidone, and 0.14 part of sodium iodide is added , stir to dissolve.

Embodiment 3

[0036] The preparation method of this embodiment is the same as that described in Example 1, except that in step a) 200 parts of distilled water are taken, 0.5 part of citric acid is added thereto, 0.01 part of polyvinylpyrrolidone, and 0.2 part of sodium iodide is added , stir to dissolve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com