Preparation method of bismuth oxychloride pearlescent pigment

A technology of bismuth oxychloride and pearlescent pigments, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of poor dispersibility, easy agglomeration, complicated process, uneven distribution of bismuth oxychloride products, etc., and achieve stable product quality. , The effect of simple process operation and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

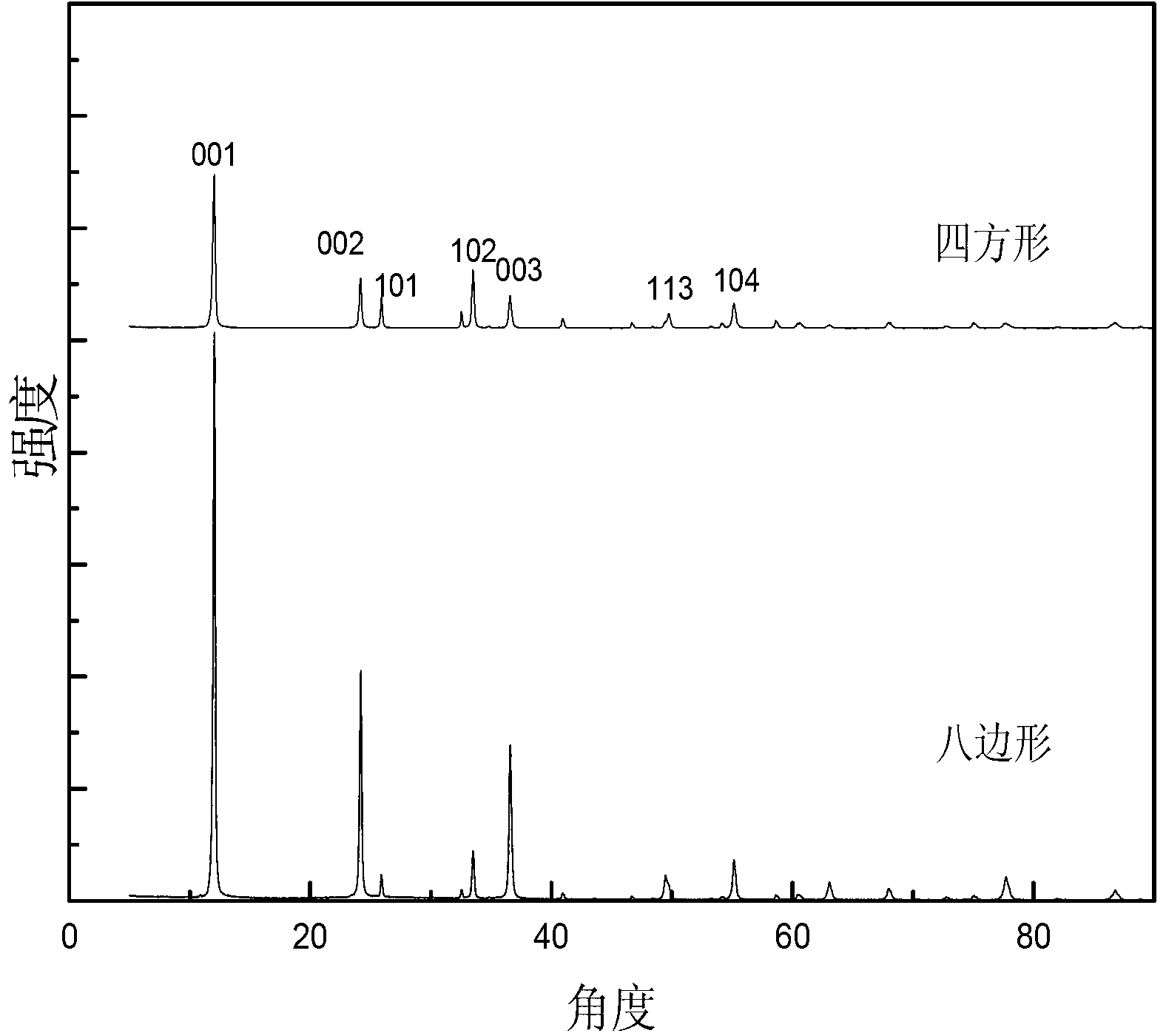

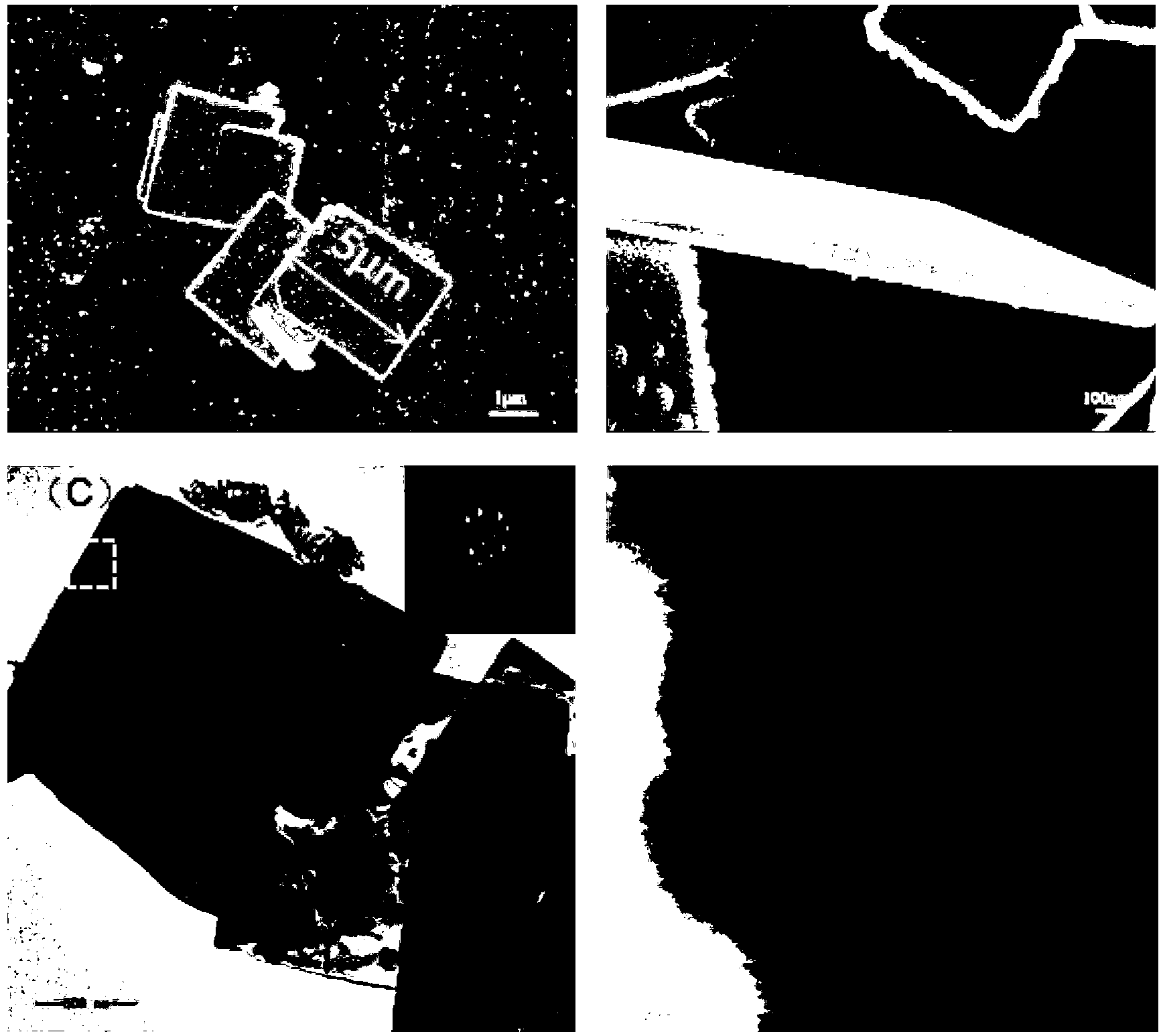

[0055] Weigh 1g of bismuth oxide and 1.7mL of concentrated hydrochloric acid with a mass fraction of 38% and place it in a beaker to form a bismuth chloride hydrochloric acid aqueous solution with a concentration of 2.5mol / L. Measure 160mL of water (the mass of bismuth chloride solution and water The ratio is 1:53) placed in a three-necked flask and heated in a water bath at 50°C, and the bismuth chloride hydrochloric acid aqueous solution was added to the water at a drop rate of 0.35mL / min under the stirring intensity of 80rpm, so that the pH of the system after the reaction was ≤1 , white bismuth oxychloride crystals were precipitated, stirred and reacted at a constant temperature of 50°C for 1 hour, filtered the final product, washed several times with appropriate amount of deionized water and absolute ethanol, and dried in an oven at 60°C for 5 hours to obtain BiOCl white pearlescent pigment with uniform dispersion, thickness of about 50nm, and cross-sectional diameter of a...

Embodiment 2

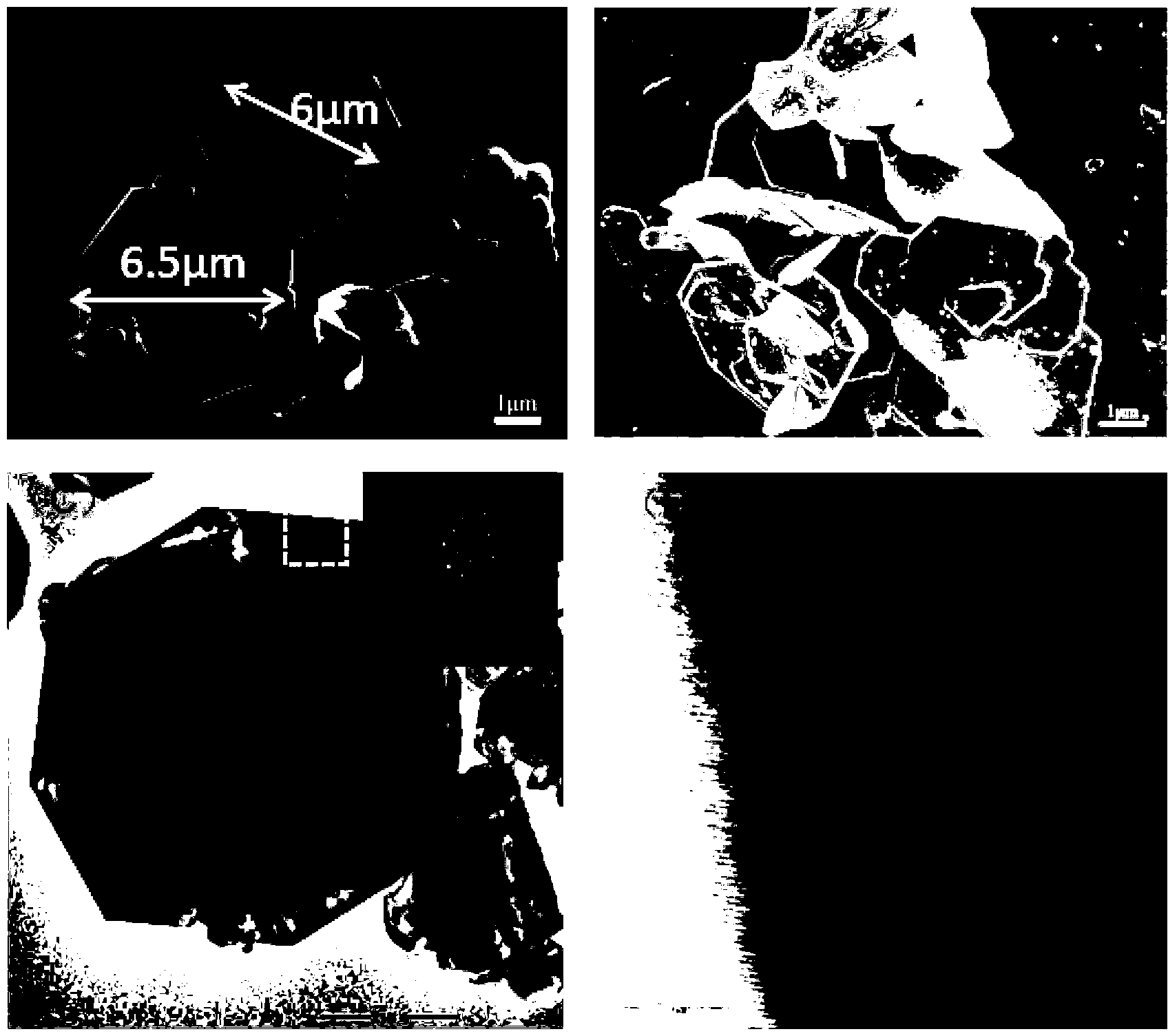

[0057] Weigh 1g of bismuth oxide and 9mL of concentrated hydrochloric acid with a mass fraction of 36% and place it in a beaker to form a bismuth chloride hydrochloric acid aqueous solution with a concentration of 0.5mol / L. Measure 160mL of water (the mass of bismuth chloride acid solution and water is 1:14) placed in a water bath in a three-necked bottle and heated at 70°C, and added bismuth chloride hydrochloric acid aqueous solution to the water at a drop rate of 3.5mL / min under a stirring intensity of 300rpm, so that the pH of the system after the reaction was ≤0.3, with White bismuth oxychloride crystals were precipitated, stirred and reacted at a constant temperature of 70°C for 2 hours, the final product was filtered, washed several times with appropriate amount of deionized water and absolute ethanol, and dried in an oven at 60°C for 5 hours to obtain uniform dispersion , The thickness is about 300nm, the cross-sectional diameter is about 5μm quadrilateral flake BiOCl w...

Embodiment 3

[0059] Weigh 1g of bismuth oxide and 2.8mL of concentrated hydrochloric acid with a mass fraction of 37.5% and place it in a beaker to form a bismuth chloride hydrochloric acid aqueous solution with a concentration of 1.5mol / L. Measure 30mL of water (the mass of bismuth chloride solution and water 1:7) placed in a three-necked flask and heated in a water bath at 90°C, and added bismuth chloride hydrochloric acid aqueous solution to the water at a drop rate of 2mL / min under a stirring intensity of 100rpm, so that the pH of the system after the reaction was ≤0.3, with White bismuth oxychloride crystals were precipitated, stirred and reacted at a constant temperature of 90°C for 0.5 hours, the final product was filtered, washed several times with appropriate amount of deionized water and absolute ethanol, and dried in an oven at 60°C for 5 hours to obtain uniform dispersion , The thickness is about 120nm, the cross-sectional diameter is about 5μm quadrilateral flake BiOCl white pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com