Patents

Literature

62results about How to "Easy for industrial scale-up production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cu-Fe-Co base catalyst used for synthesizing low carbon alcohol by utilizing synthesis gas as well as preparation method and application thereof in low carbon alcohol synthesizing process by virtue of synthesis gas

ActiveCN102247852ALow costEasy to prepareOrganic compound preparationHydroxy compound preparationRare-earth elementChemistry

The invention provides a Cu-Fe-Co base catalyst which has higher C2<+> alcohol selectivity and is used for synthesizing low carbon alcohol by utilizing synthesis gas and a preparation method thereof. The expression of the catalyst is CuaFebCocMd / SiO2, or CuaFebCocMd / Al2O3 or CuaFebCocMd / (SiO2+Al2O3), wherein M is one or a combination of more than one of transitional metal element, alkali metal, alkaline earth metal and rare-earth element, and a catalyst carrier is SiO2 or Al2O3 or a mixture of SiO2 and Al2O3; and loaded active components Cu, Fe, Co and M in the catalyst respectively account for a, b, c and d of the total weight of the catalyst (wt%), a is 10-35%, b is 10-35%, c is 1-10%, d is 0-5%, and the catalyst carrier accounts for 15-79%. The catalyst is prepared by adopting the steps of impregnation and substep reduction. The Cu-Fe-Co base catalyst provided by the invention can be applied to the low carbon alcohol process by virtue of the synthesis gas. The catalyst provided by the invention has low cost, a simple preparation method and stable performance, and the industrial amplification production is easy to realize; and compared with similar catalysts, the catalyst provided by the invention has mild reaction conditions and low reaction equipment requirements when being used for synthesizing the low carbon alcohol by utilizing the synthesis gas.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

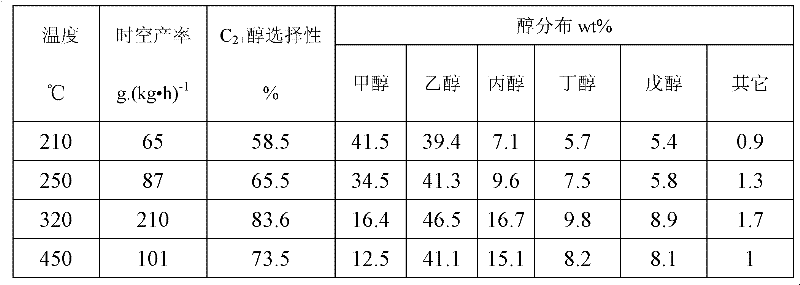

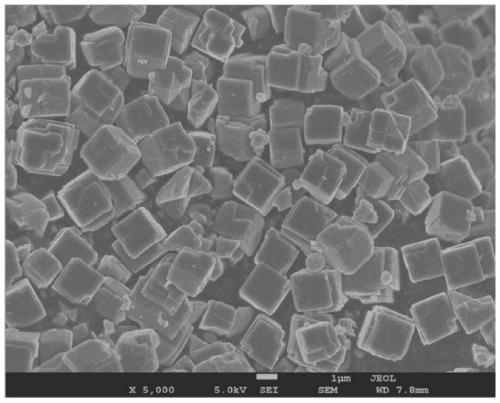

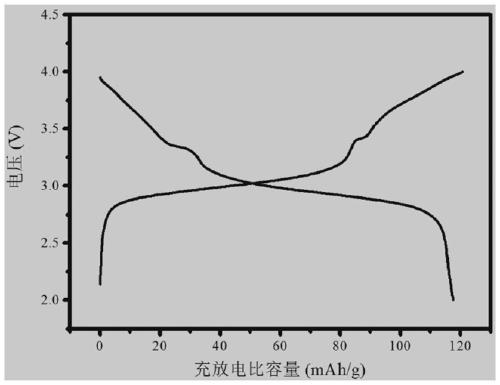

Prussian blue cathode material with high sodium content, preparation method and applications thereof, and sodium ion battery

ActiveCN110235292AGood effectRaise the sodium contentIron cyanidesSecondary cellsHigh sodiumPrussian blue

The invention belongs to the technical field of novel energy storage materials, and relates to a Prussian blue cathode material with a high sodium content, a preparation method and applications thereof, and a sodium ion battery. The molecular formula of the Prussian blue cathode material is Na<x>MNFe(CN)<6>; wherein M and N represent a same transition metal or different transition metals andcan be Fe, Co, Mn, Ni, Cu, Zn, Cr, V, Zr, or Ti; 1.8<x<2; 0<a<1; 0<b<1; and a+b=1. The cathode material has millimeter cubic morphology and excellent electrochemical properties. The preparation method has the advantages that the crystallization is slow, the sodium content of the cathode material is high, the preparation method is simple and easy to perform, the production efficiency and the yieldare high, the raw materials are cheap, and industrial production and enlarged production are easy to realize.

Owner:LIAONING STARRY SKY SODIUM BATTERY CO LTD

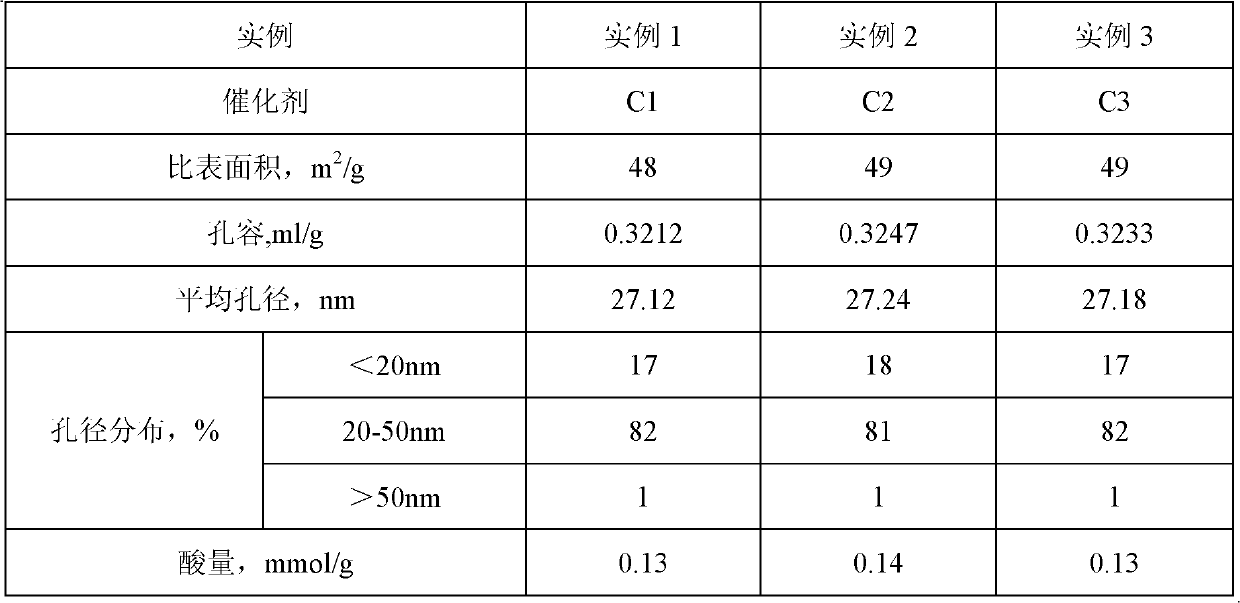

Preparation method of catalyst for selective hydrogenation of alkyne and alkadiene

InactiveCN103372432AGenerate good effectReduce churnHydrocarbon purification/separationHydrocarbonsAlkaline earth metalCerium

The invention relates to a preparation method of a catalyst for the selective hydrogenation of alkyne and alkadiene. A carrier of the catalyst is a compound of 30-99% of aluminum oxide, 1-50% of titanium oxide, 1-30% of magnetism oxide and 1-40% of zinc oxide based on the weight of the carrier of the catalyst as 100%; meanwhile, an alcohol reagent and an alkali metal or an alkaline-earth metal are used as modifying reagents; the preparation method is an acidity sol mixed kneading molding method; the active components of the catalyst comprise three or more of palladium, gold, silver, bismuth, cerium, lanthanum, tin and antimony, and a loaded solution of the active components is subjected to polymerization; the carrier of the catalyst prepared by the method has relatively low acid content; and the prepared catalyst shows up relatively appropriate reaction activity in the selective hydrogenation reaction of the alkyne and the alkadiene and has relatively good hydrogenation selectivity, relatively strong green oil generation resistance and relatively low palladium wastage rate.

Owner:PETROCHINA CO LTD

Preparation method for organic activated clay used for decolorization

InactiveCN104096543ALarge specific surface areaImprove pore structureOther chemical processesWater/sewage treatment by sorptionWater basedClay minerals

The invention provides a preparation method for organic activated clay used for decolorization. The preparation method comprises the following steps: clay mineral is grinded into powder and the powder is subjected to water rinsing at the temperature of 50-80 DEG C; the obtained rinsed clay powder is subjected to modification processing in an acid solution of 3-20 weight percent at the temperature of 60-90 DEG C for 2-5 h; a cationic surfactant is added into the obtained clay based activated clay at the temperature of 50-90 DEG C to react continuously for 2-8 h to obtain slurry; the obtained slurry is filtered, washed and dried in a drying oven; the dried materials are pulverized and screened to obtain organic activated clay powder greater than 200 mesh, wherein the adding amount of the cationic surfactant is 5-50 weight percent of the weight of the activated clay. According to the preparation method, non-metallic clay mineral is adopted as raw materials and subjected to rinsing, acidifying and organic processing for preparing clay mineral based organic activated clay which is suitable for desorbing coloring matters and organic pollutant in water-based system, the preparation method is simple, the cost is low, the industrial magnification production is facilitated and the organic activated clay has better application prospect in the field of wastewater treatment and biological processing.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

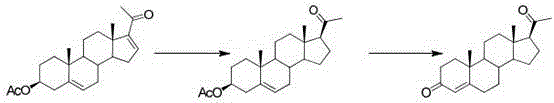

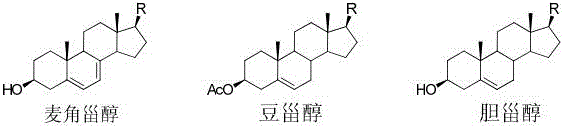

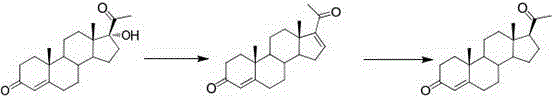

Method for preparing progesterone and derivatives thereof

InactiveCN106589037AReduce manufacturing costEasy to operateSteroidsProgesteronesRearrangement reaction

The invention discloses a method for preparing progesterone and derivatives thereof. A compound 1 serves as a starting material, and through an oxidation reaction and a rearrangement reaction, the progesterone and derivatives thereof, namely, compounds 3 are obtained, wherein the reaction formula is defined in the description. By means of the method, the finished product progesterone and derivatives thereof are obtained with the total yield being 75wt% or above; the method is low in cost, environmentally friendly and suitable for industrial production.

Owner:ZHEJIANG XIANJU PHARMA

Loaded palladium catalyst and preparing method and its use

InactiveCN1748860AImprove hydrogenation activityMild reaction conditionsCatalyst carriersCatalyst activation/preparationFiberActive component

The present invention belongs to the field of the preparation of palladium catalyst, and is especially supported palladium catalyst and its preparation process and application. The supported palladium catalyst is noble metal palladium supported onto nanometer alumina fiber carrier and has the supported amount of palladium as the active component in 0.1-1 wt%. The nanometer alumina fiber carrier is gamma-alumina fiber, and the noble metal palladium is supported onto the nanometer alumina fiber carrier through equal volume soaking process. The high dispersive supported palladium catalyst is used in hydrogenating anthraquinone to prepare hydrogen peroxide solution, has high hydrogenating effect and mild reaction condition, and suitable for industrial production.

Owner:NANKAI UNIV

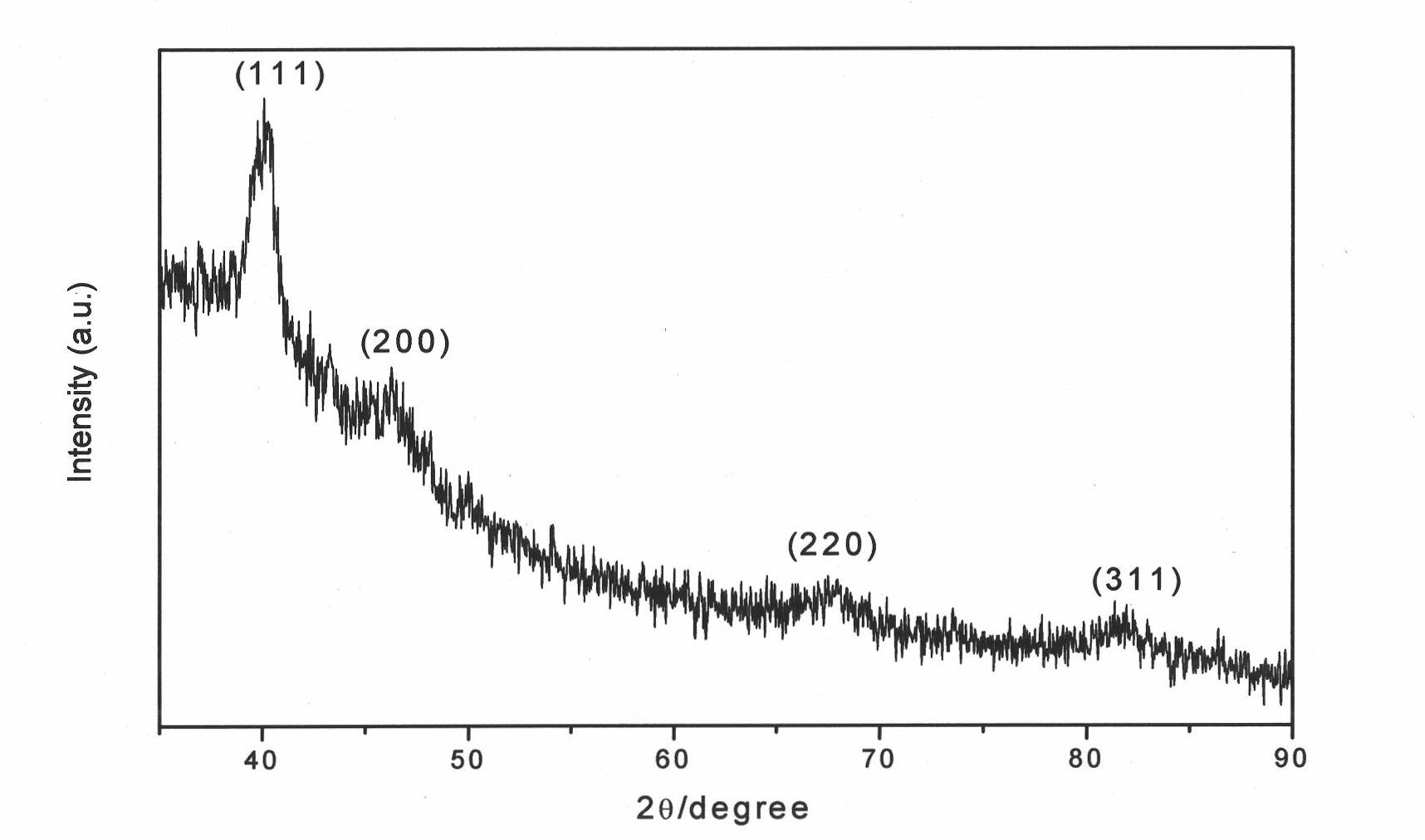

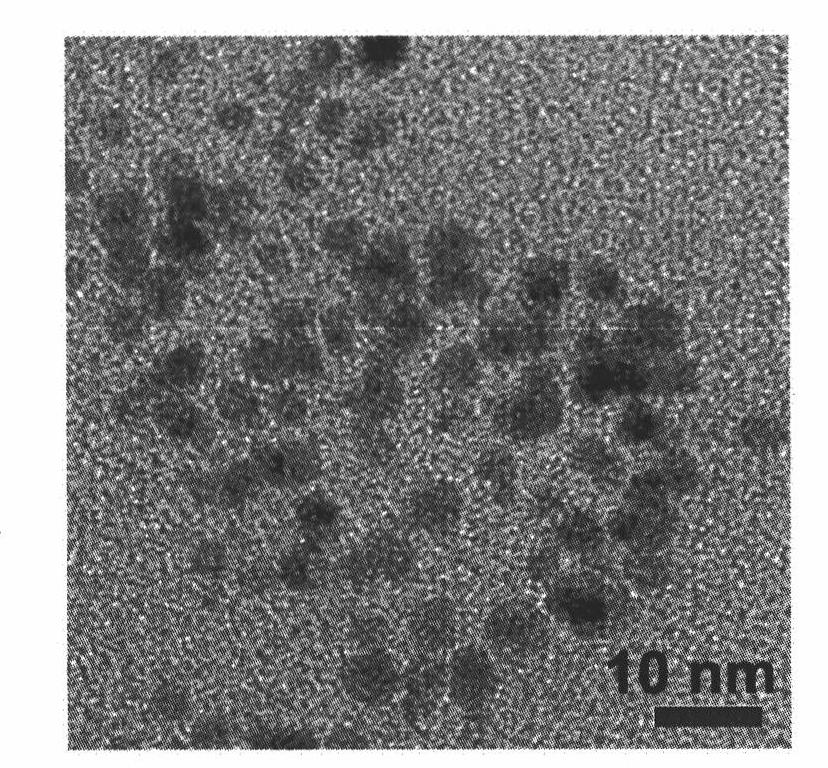

Nanometer palladium catalyst for hydrogenation of anthraquinone and preparation method thereof

InactiveCN101804346AImprove hydrogenation efficiencyReduce dosageCatalyst carriersPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthranilNanoparticle

The invention relates to a nanometer palladium catalyst for hydrogenation of anthraquinone and a preparation method thereof, relating to a palladium catalyst. The invention provides the nanometer palladium catalyst for the hydrogenation of anthraquinone and the preparation method thereof, wherein natural plants are taken as a reducing agent and a carrier. The nanometer palladium catalyst is prepared by dispersing nanometer palladium granules on a Cape jasmine carrier, and based on weight percent, the loaded palladium accounts for 1.2-3.6 percent of Cape jasmine, and the size of the nanometer palladium granules is 3-10 nm. Cape jasmine lixivium is prepared by dipping Cape jasmine in water, and the nanometer palladium catalyst is prepared by preparing palladium chloride into palladium chloride and Cape jasmine mixing solution by using the Cape jasmine lixivium, reducing and drying to obtain the nanometer palladium catalyst loaded on the Cape jasmine, i.e. the nanometer palladium catalyst for the hydrogenation of anthraquinone.

Owner:XIAMEN UNIV

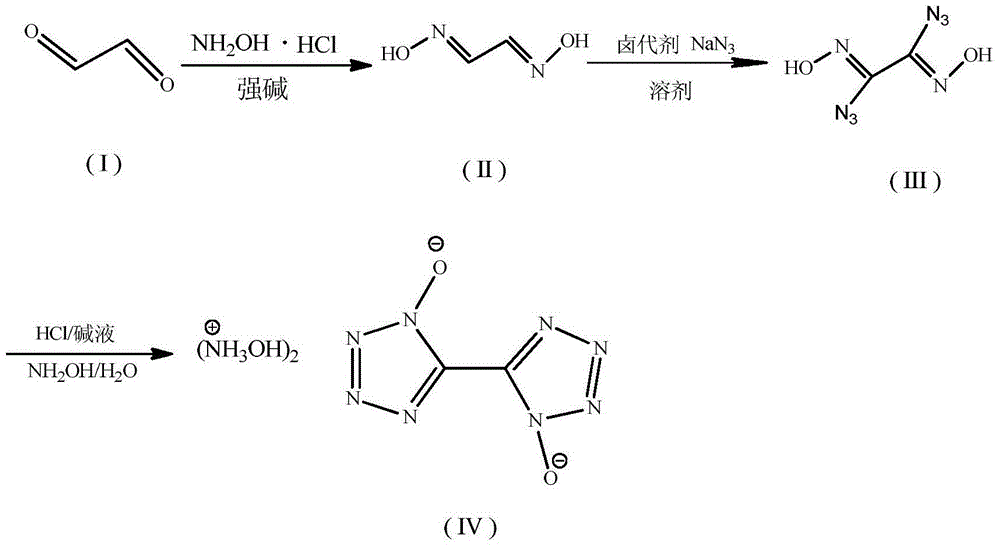

5, 5 '-bistetrazole-1, 1'-dioxo hydroxylammonium salt synthetic method

InactiveCN104829548AThe process is highly toxicReduce yieldOrganic chemistryOrganic synthesisGlyoxal

The invention relates to a 5, 5 '-bistetrazole-1, 1'-dioxo hydroxylammonium salt synthetic method, and belongs to organic synthesis technical field. According to the method, glyoxal is used as a raw material, and TKX-50 is obtained by changing of intermediate raw materials, a reaction solvent and technological conditions; the second step is direct preparation of diazido glyoxime by use of one pot method, reaction conditions are mild, the intermediate links are reduced, and the product yield is improved. The third step is direct introduction of HCl gas for preparation of BTO without separation of the high sensitivity diazido glyoxime, BTO salt can be obtained by use of an alkaline solution, later period control of TKX-50 purity is facilitated, product quality can be improved, and the whole reaction overall yield is more than 72%. According to the method, a lot of intermediate operation links can be reduced, the product yield is improved, and the method helps to achieve industrial production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Tech, Process for dimethyl violuric acid catalyzing hydrogenation reaction

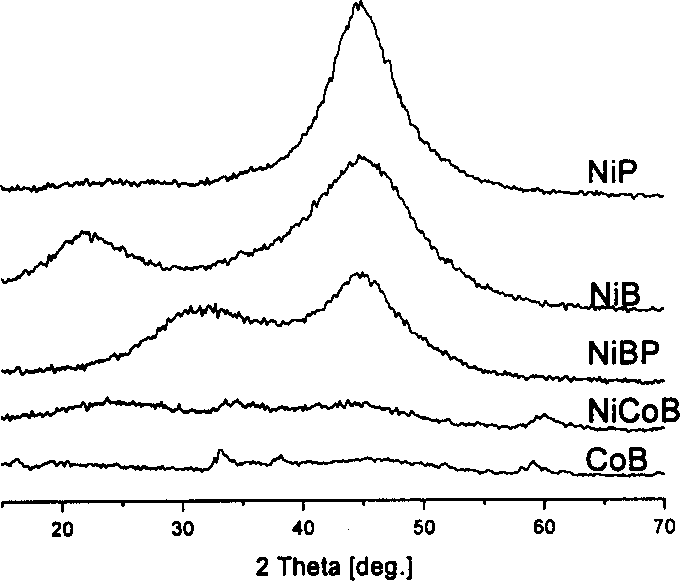

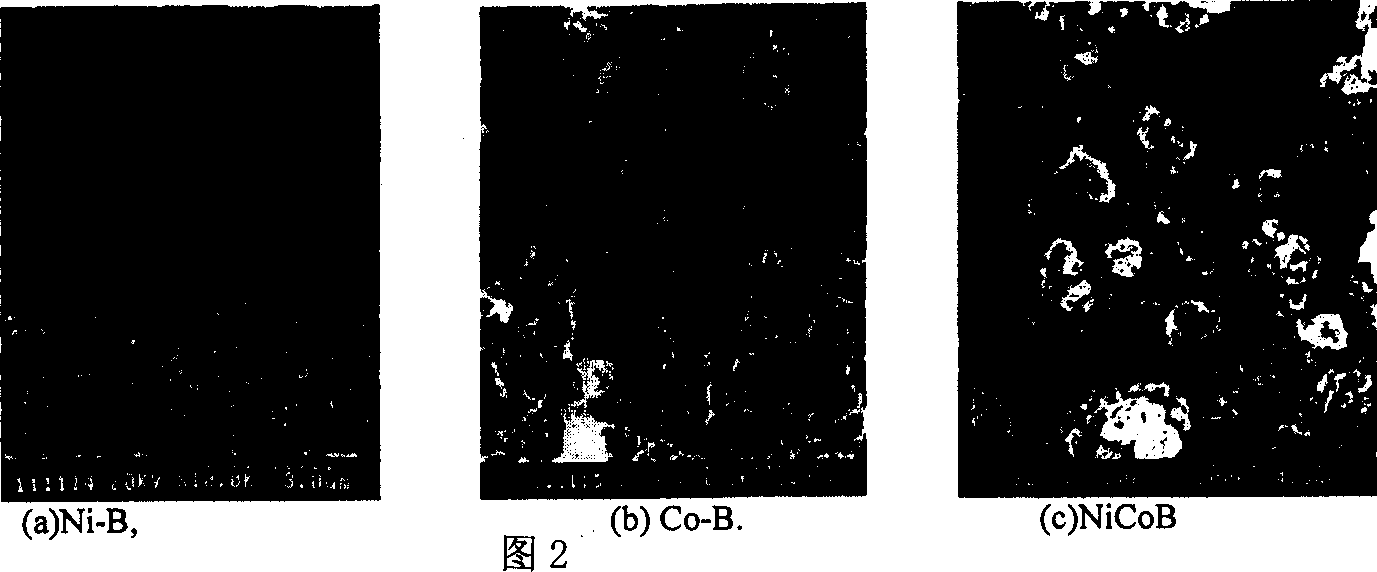

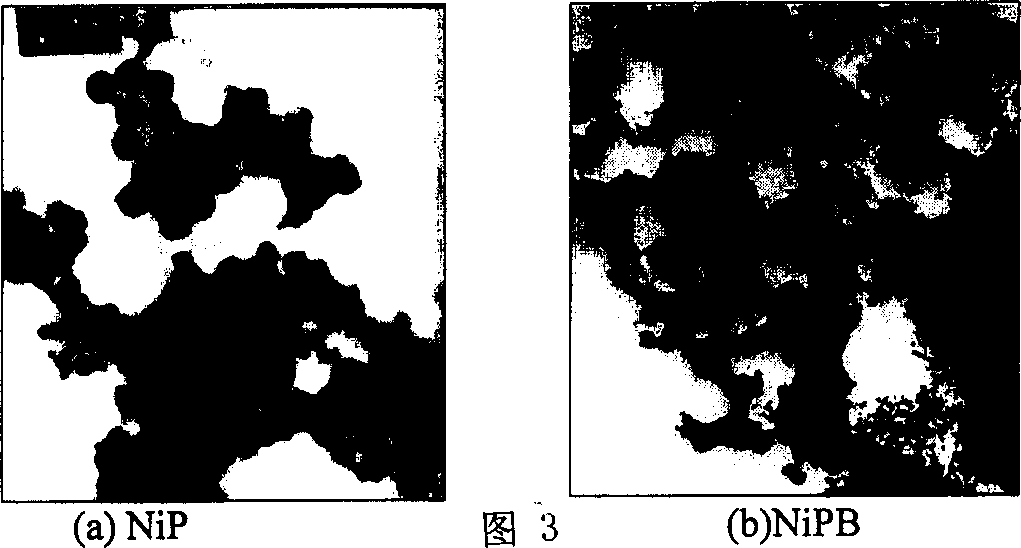

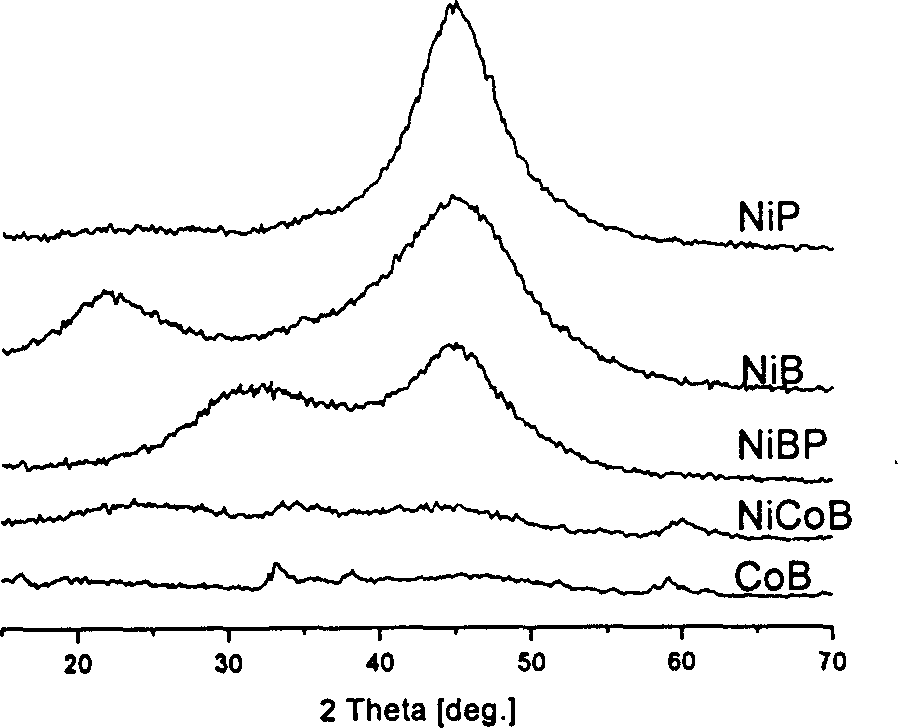

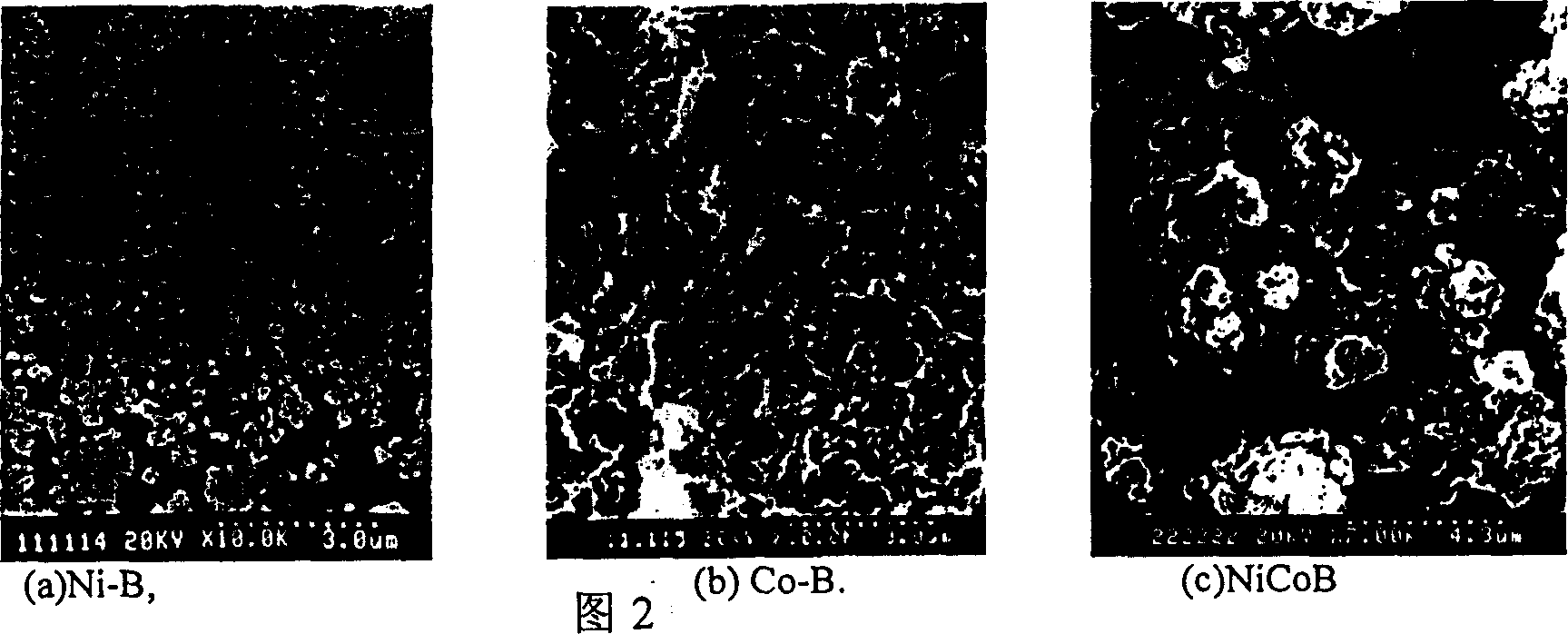

InactiveCN1793139ANo pollution in the processHigh catalytic activityOrganic chemistryHydrogenation reactionAlloy catalyst

The invention relates to a technology method dimethyl purple urea acid catalyst hydrogenation reaction that uses inorganic oxygen as carrier, uses load type NiB, NiCoB amorphous alloy as catalyst and dimethyl purple urea acid hydrogenation reacting to make 1, 3-dimethyl-4-amino group-5-formamido urea. The invention has good catalyst activity in dimethyl purple urea acid hydrogenation reacting, and has no influent by high temperature. It is save, no pollution, mild reacting condition, and simple technology.

Owner:天津市瑞凯科技发展有限公司

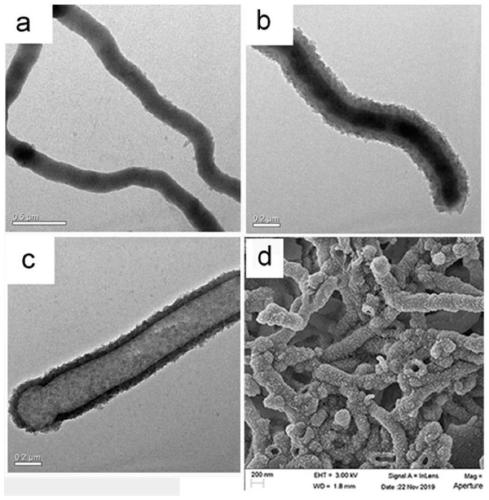

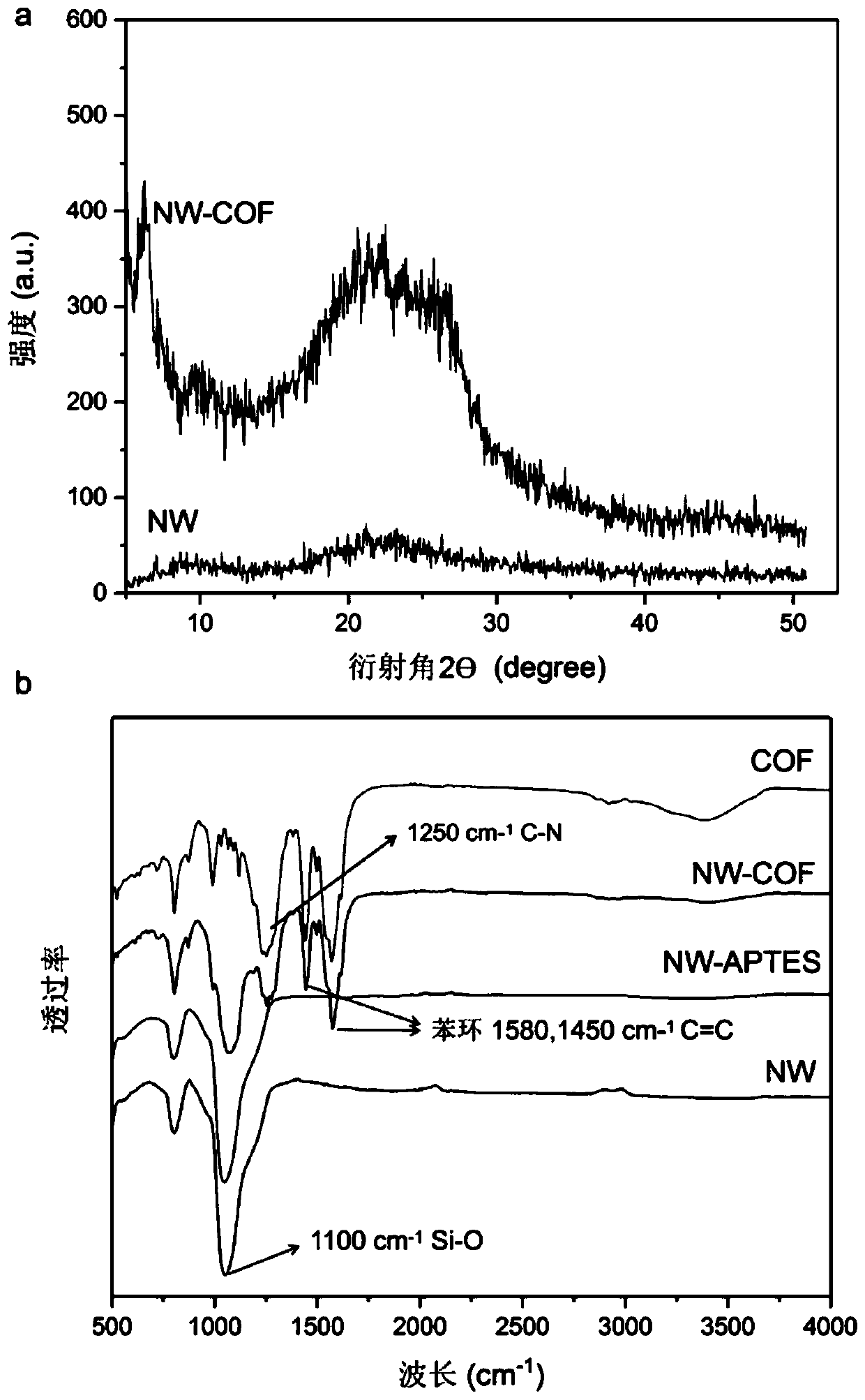

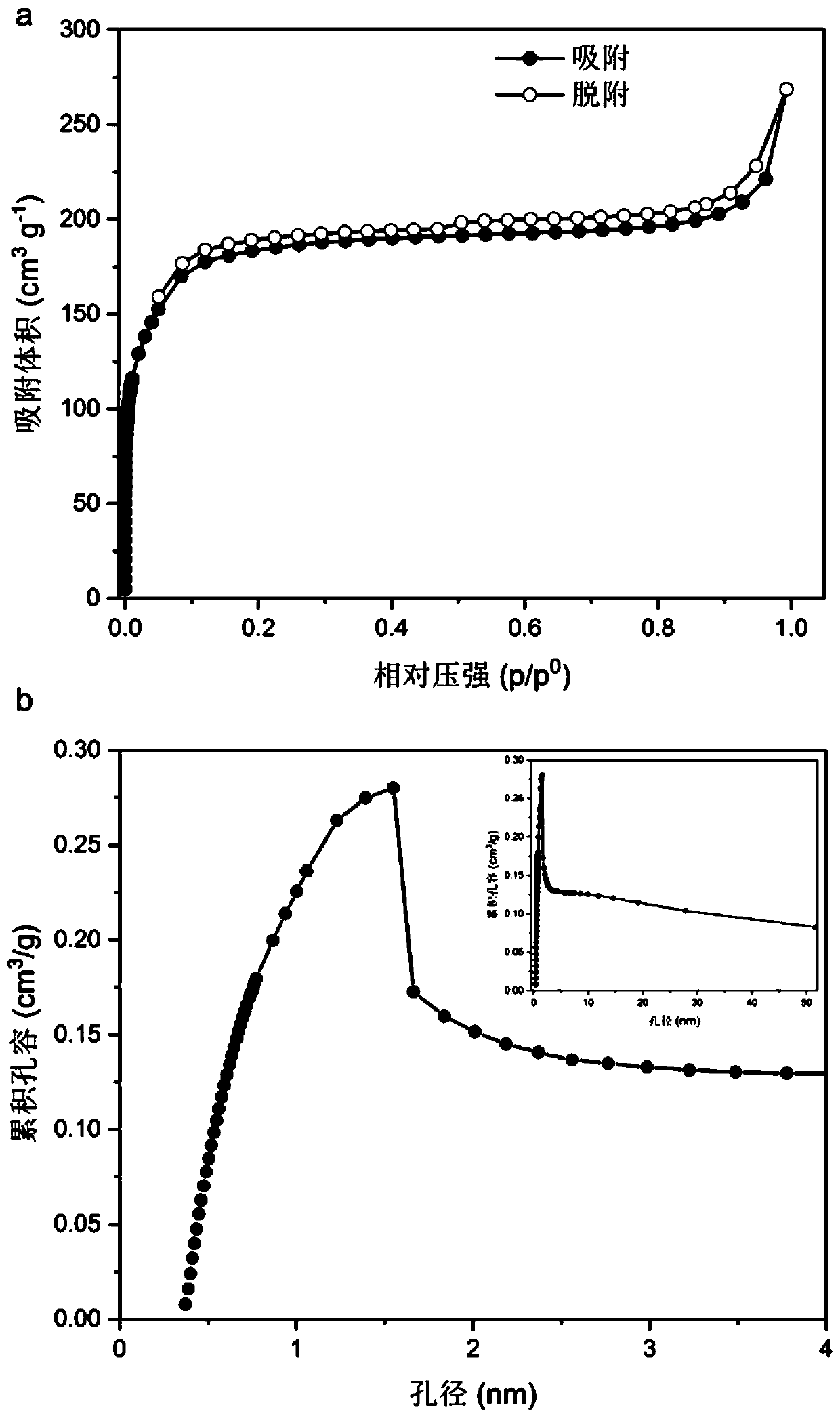

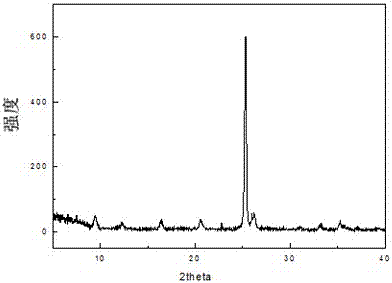

Covalent organic framework (COF) nanotube, and preparation method and application thereof

The invention belongs to the technical field of nanometer materials, and particularly relates to a COF nanotube, and a preparation method and application thereof. According to the method, silicon dioxide nanowires are used as a hard template, and the silicon dioxide nanowires can be deposited on the surfaces of stainless steel wires and other materials through soaking and extraction methods to form a silicon dioxide nanowire film; and with the dispersed silicon oxide nanowires or the film with the deposited silicon dioxide nanowires as a substrate, a layer of COF film grows in situ, and the silicon oxide nanowire template is etched to respectively obtain the dispersed COF nanotube and a stainless steel wire modified by a COF nanotube film. Due to rich micropores of the COF, the COF nanotube has a very high specific surface area, and a hollow pipeline structure provides a rapid substance transmission channel for molecules, so the COF nanotube is an ideal separation and enrichment material and can be used for effectively enriching trace organic pollutants in a solution. The stainless steel wire modified by the COF nanotube film can be used as a stainless steel wire solid-phase micro-extraction head and is used as a pretreatment material for quantitative enrichment and purification of harmful substances.

Owner:FUDAN UNIV

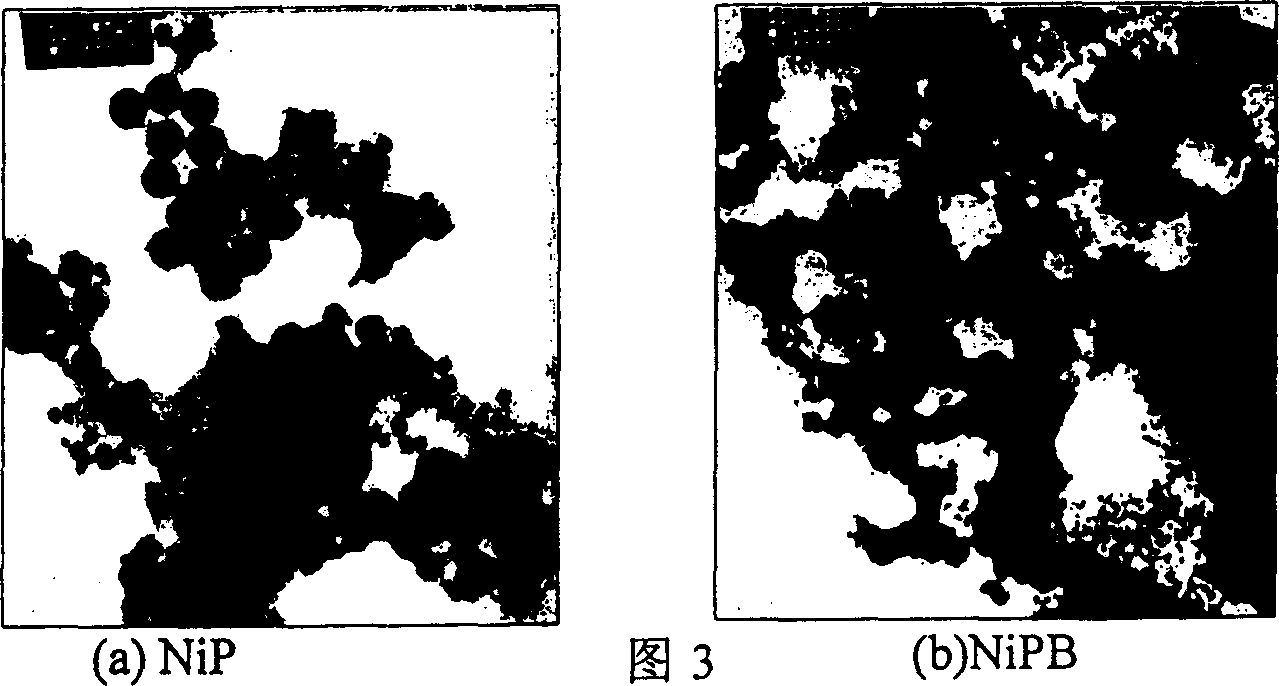

Amorphous alloy catalyst for hydrogenating cyclobufene sultone and its prepn. and application

InactiveCN1375357ANo pollution in the processHigh low temperature activityPhysical/chemical process catalystsOrganic chemistryPtru catalystMetallurgy

The present invention relates to a catalyst for cyclobutenesulfphone hydrogenation, its general formula is NixCoyBmPn, in which x=0-80, y=0.70, m=0-50 and n=0-50. It is an amorphous alloy, and possesses high low-temp. activity, and is easy to industrial production.

Owner:NANKAI UNIV

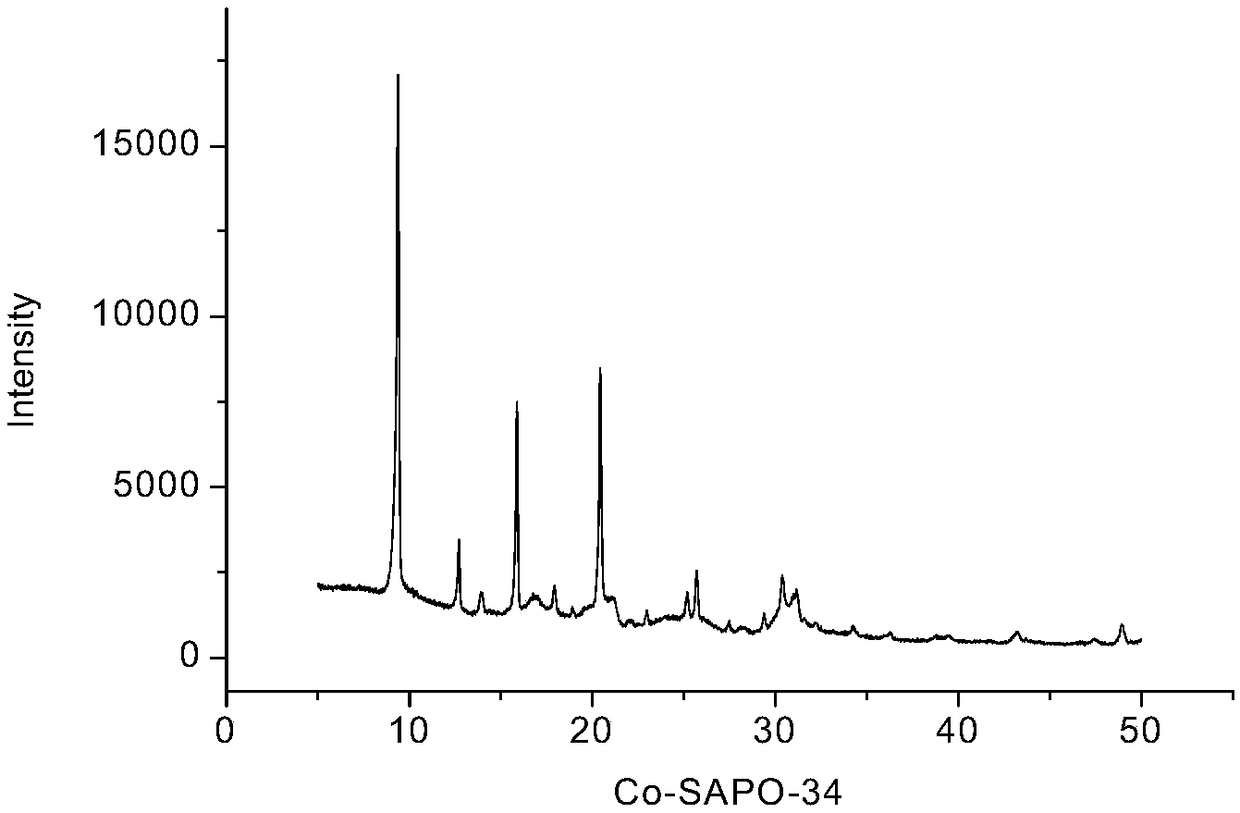

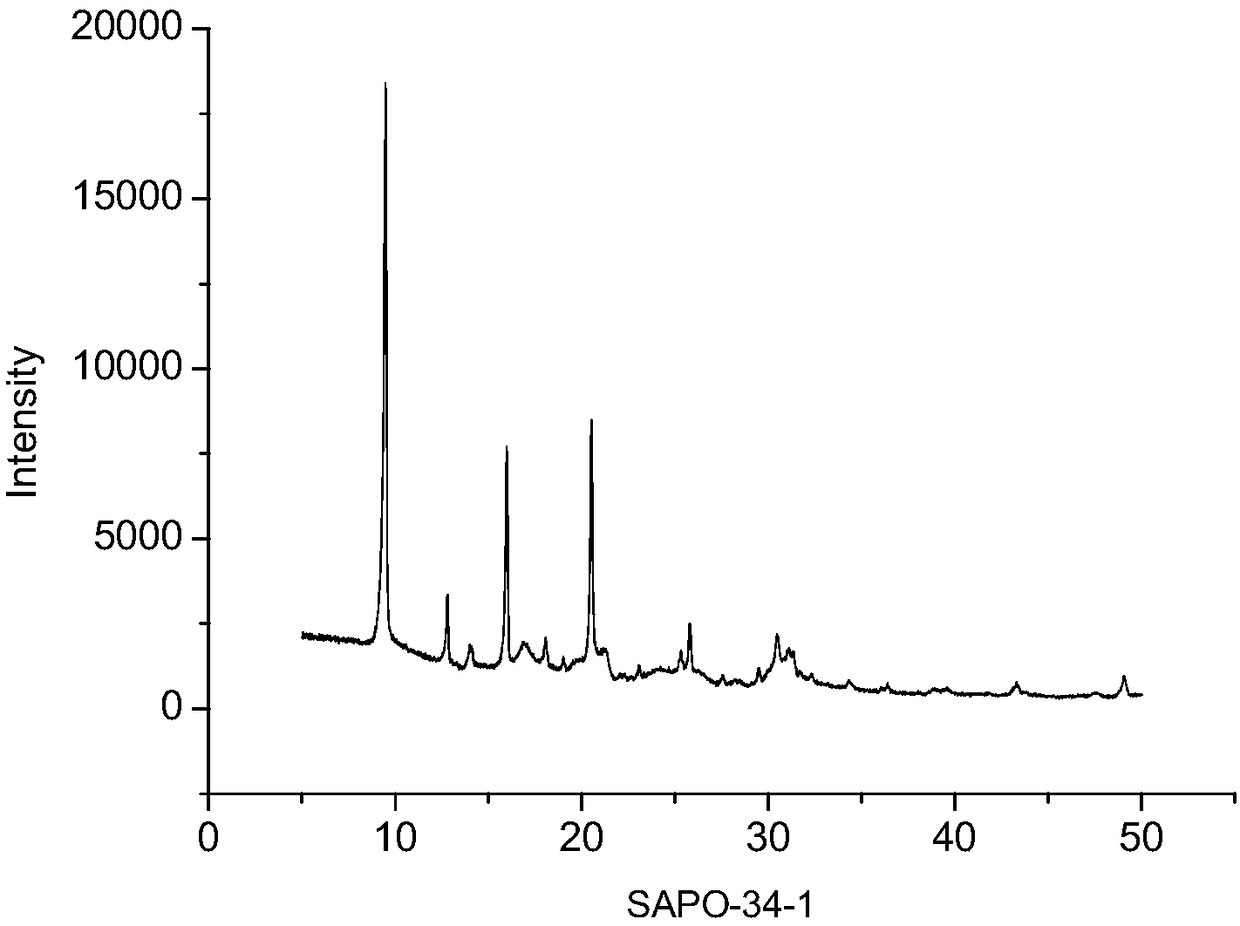

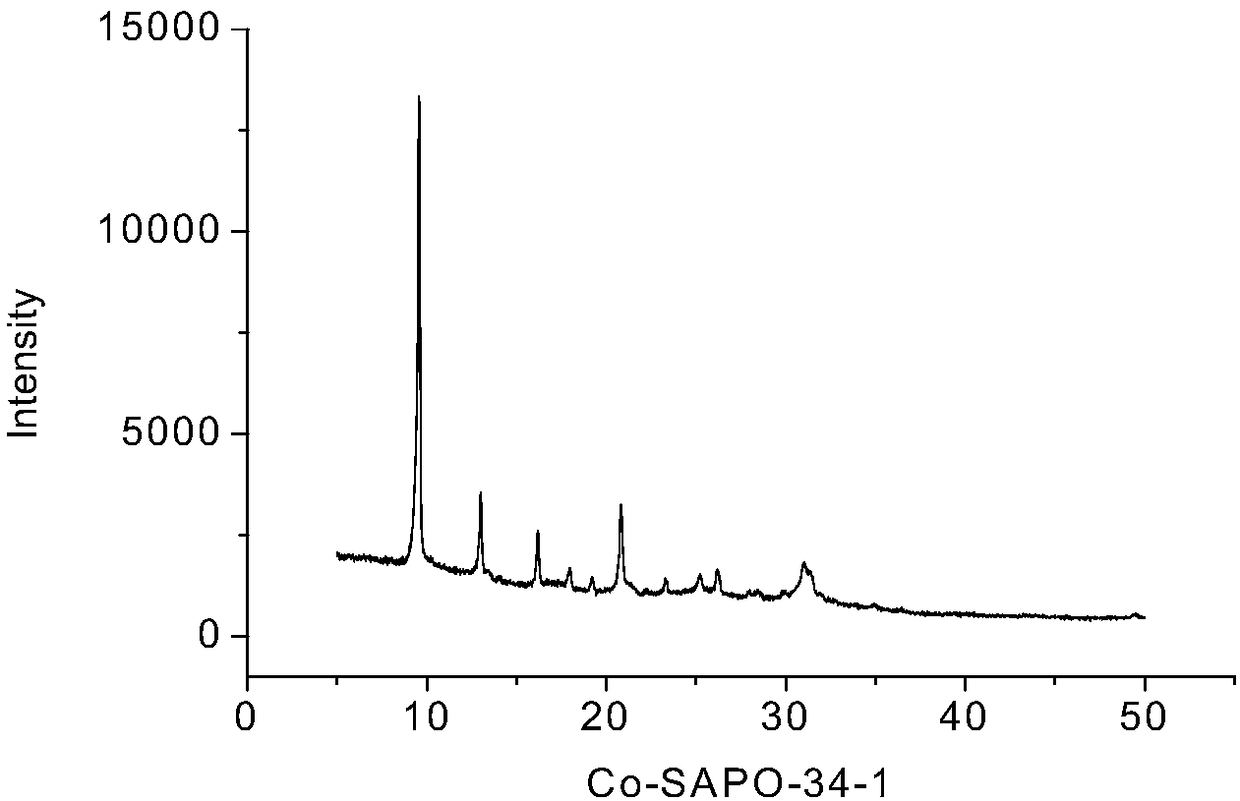

Method for synthesizing metal-modified SAPO-34 molecular sieve

ActiveCN108249458AThe role of metal modification is fully exertedHigh crystallinityMolecular sieve catalystsMolecular sieve catalystMolecular sieveAlkene

The invention discloses a method for synthesizing a metal-modified SAPO-34 molecular sieve. The method comprises the following steps: preparing a metal salt into an aqueous solution; adding an aluminum source to be stirred uniformly; then, filtering, washing, drying, calcining at a low temperature, and then re-dispersing in a small amount of water; sequentially adding a phosphorus source, a silicon source and a template agent; stirring to form a gel mixture; and ageing, crystallizing, washing, drying and calcining to prepare the metal-modified SAPO-34 molecular sieve. The metal-modified SAPO-34 molecular sieve prepared in the invention has relatively high crystallinity, shows high low-carbon olefin selectivity when use for catalyzing reaction of preparing olefin from methanol, has the advantages of high ethylene selectivity, yield, low synthesis costs and easy industrial large-scale production.

Owner:深圳科冠华太新材料技术有限公司

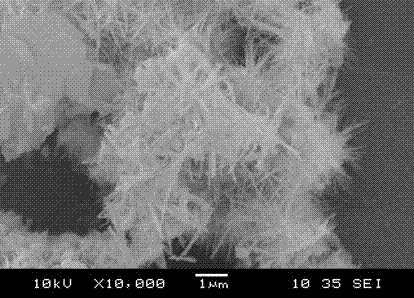

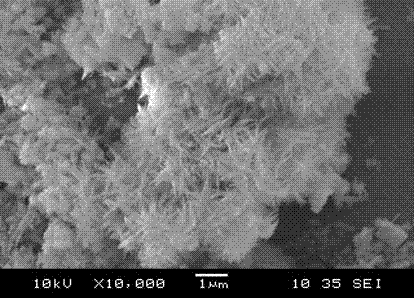

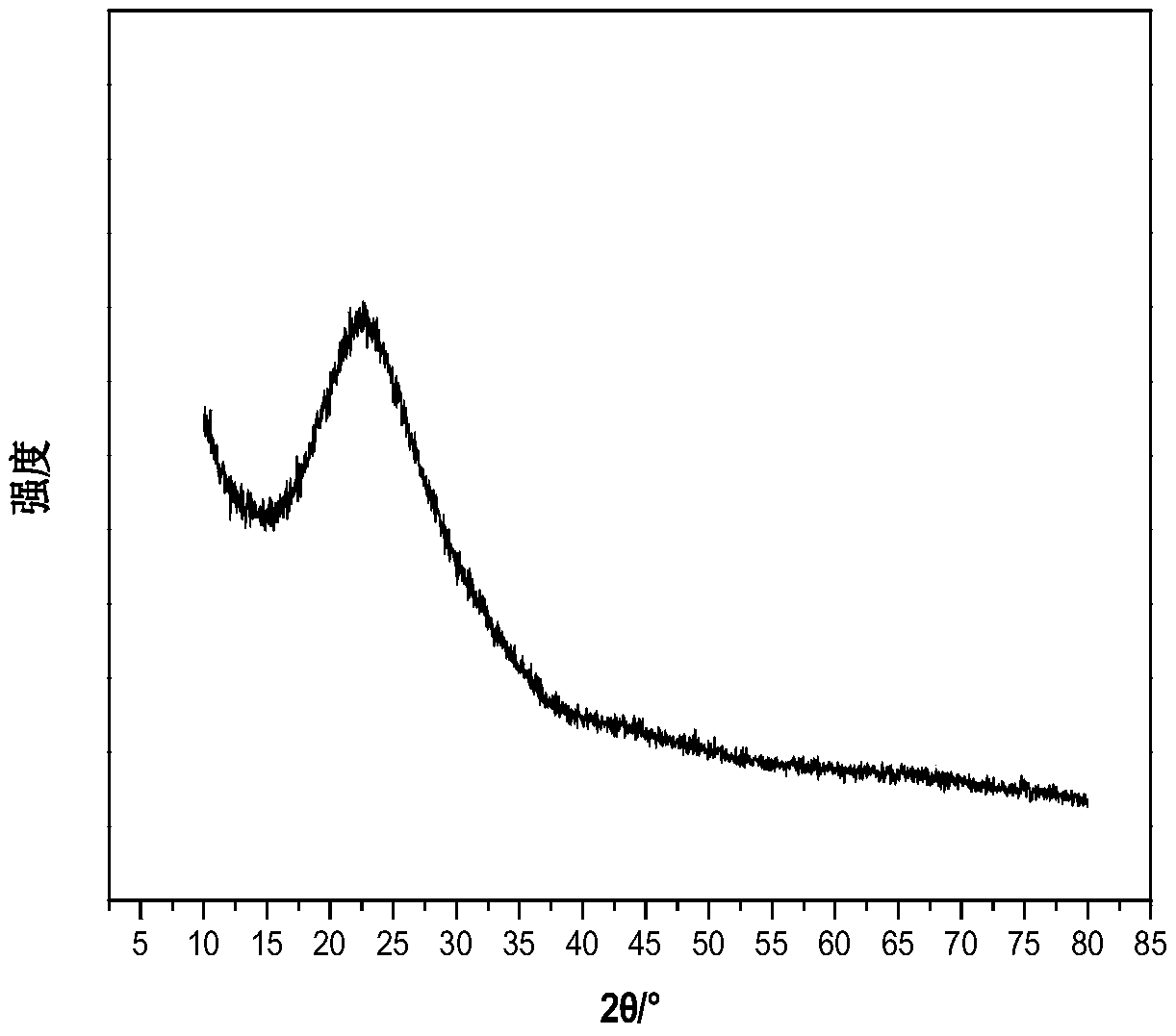

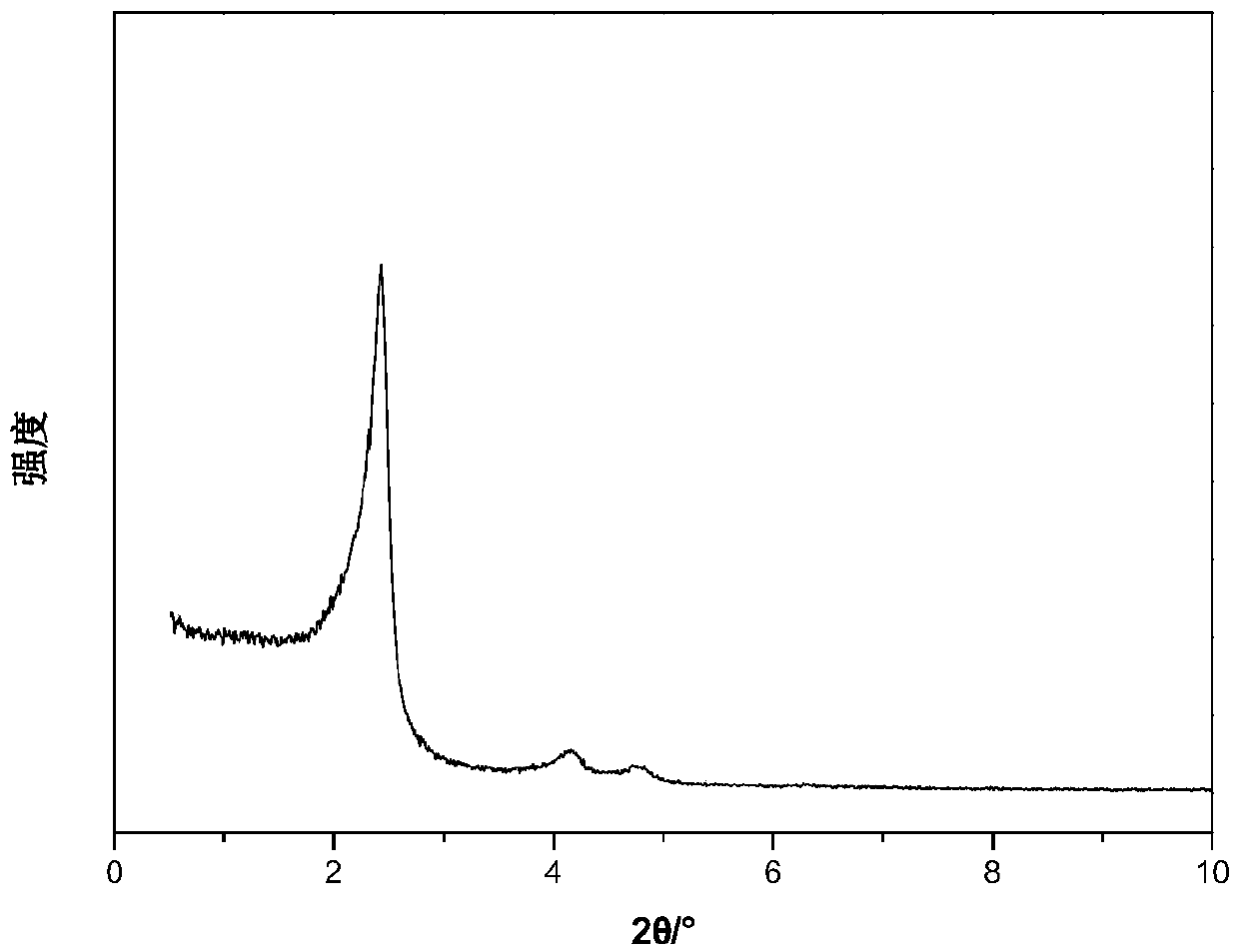

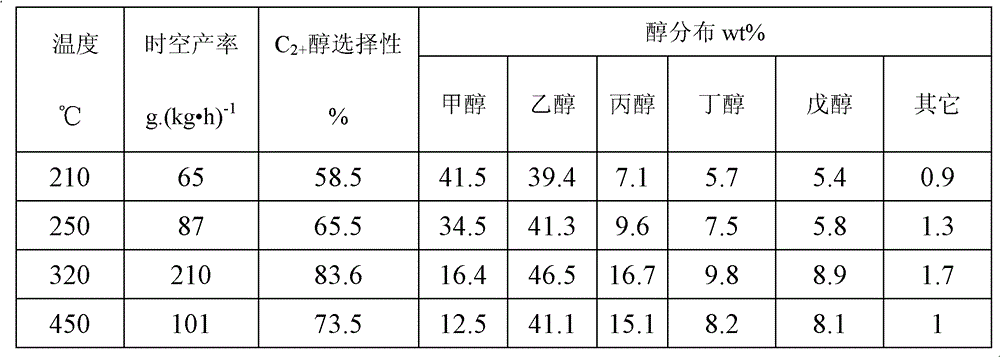

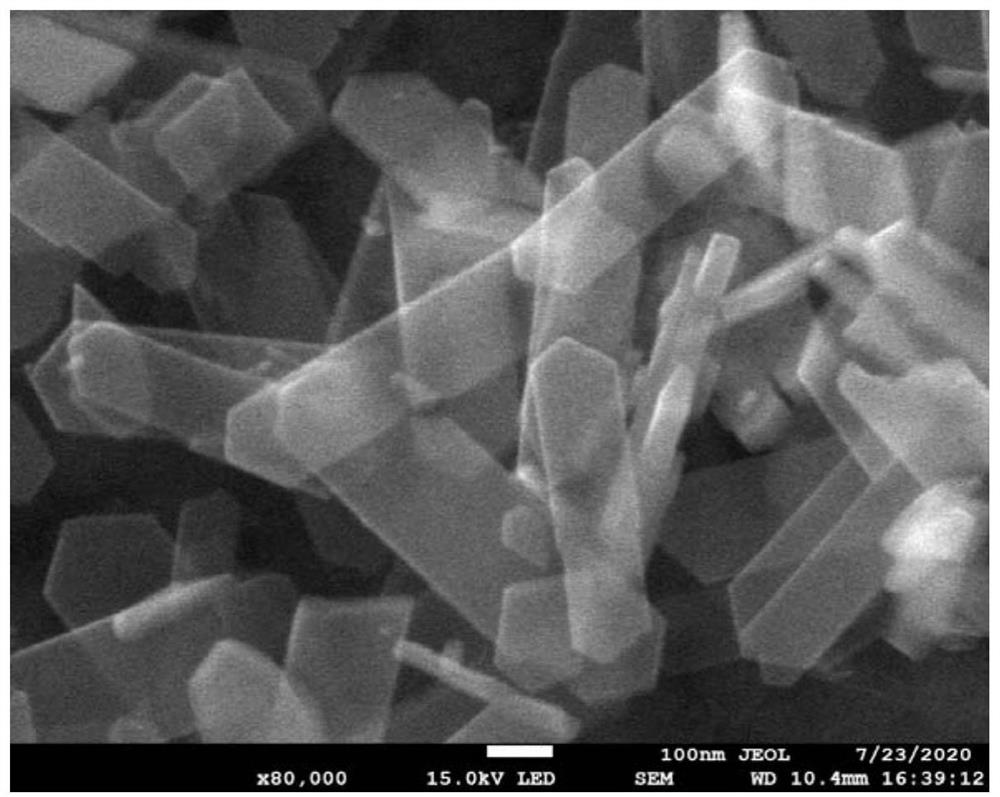

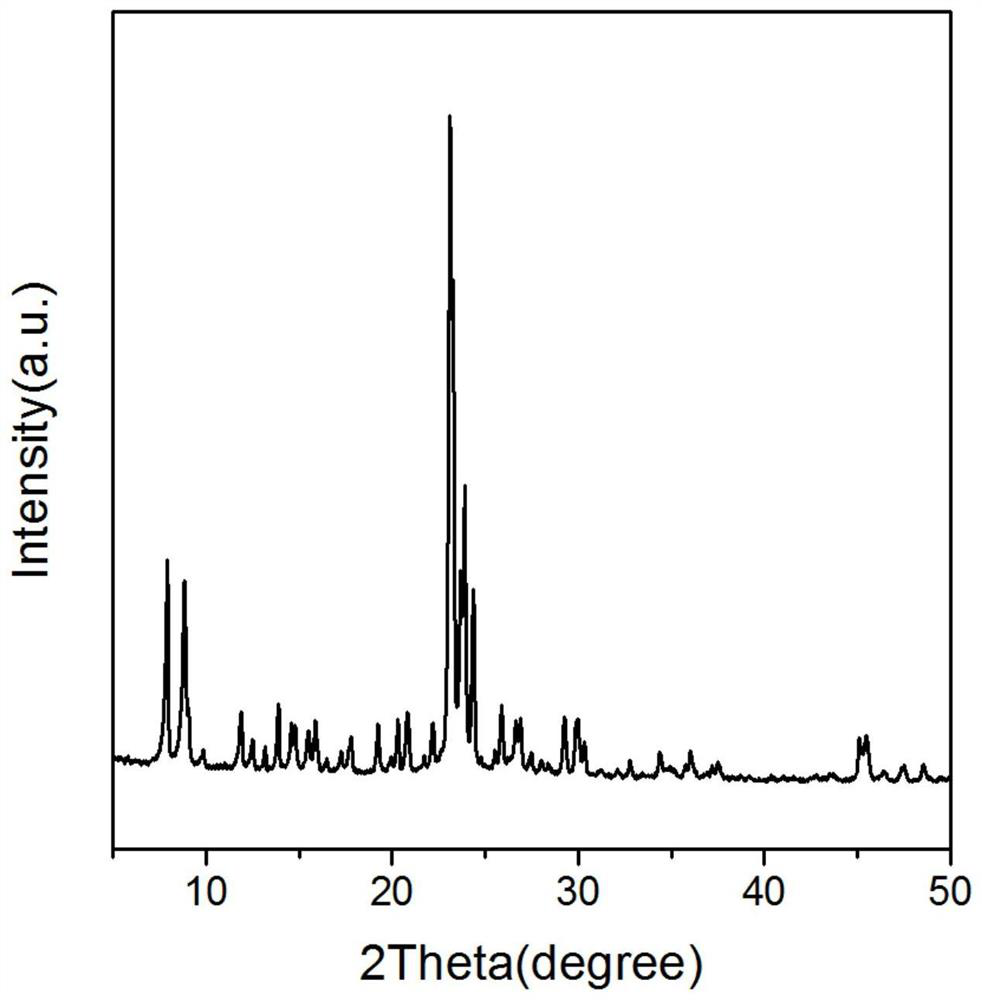

Nanometer needle-shaped SAPO-34 molecular sieve, as well as preparation and application thereof

ActiveCN107055563AHigh crystallinityImprove transmission performanceMaterial nanotechnologyMolecular-sieve and base-exchange phosphatesMolecular sieveActive component

The invention relates to a nanometer needle-shaped SAPO-34 molecular sieve, as well as preparation and application thereof. A gel decondensation hydrothermal synthesis method is adopted and particularly comprises the following steps: (1) mixing an aluminum source, a phosphorus source, a silicon source, deionized water and a template agent, heating and stirring to obtain gel A; (2) adding excessive HF solution into the gel A, wherein the gel is decondensed into a solution at this moment; (3) performing hydrothermal crystallization: transferring the solution obtained in the step (2) into a polytetrafluoroethylene reaction kettle, performing high-temperature crystallization, rapidly cooling after the crystallization is completed, filtering and washing the obtained solid, drying and roasting to obtain the nanometer needle-shaped SAPO-34 molecular sieve. The preparation process is simple and easy to operate, and the molecular sieve has important application in methanol to olefin reaction; meanwhile, due to the special shape, the molecular sieve can serve as a carrier of catalyst active components and has potential industrial application prospect.

Owner:SHANTOU UNIV

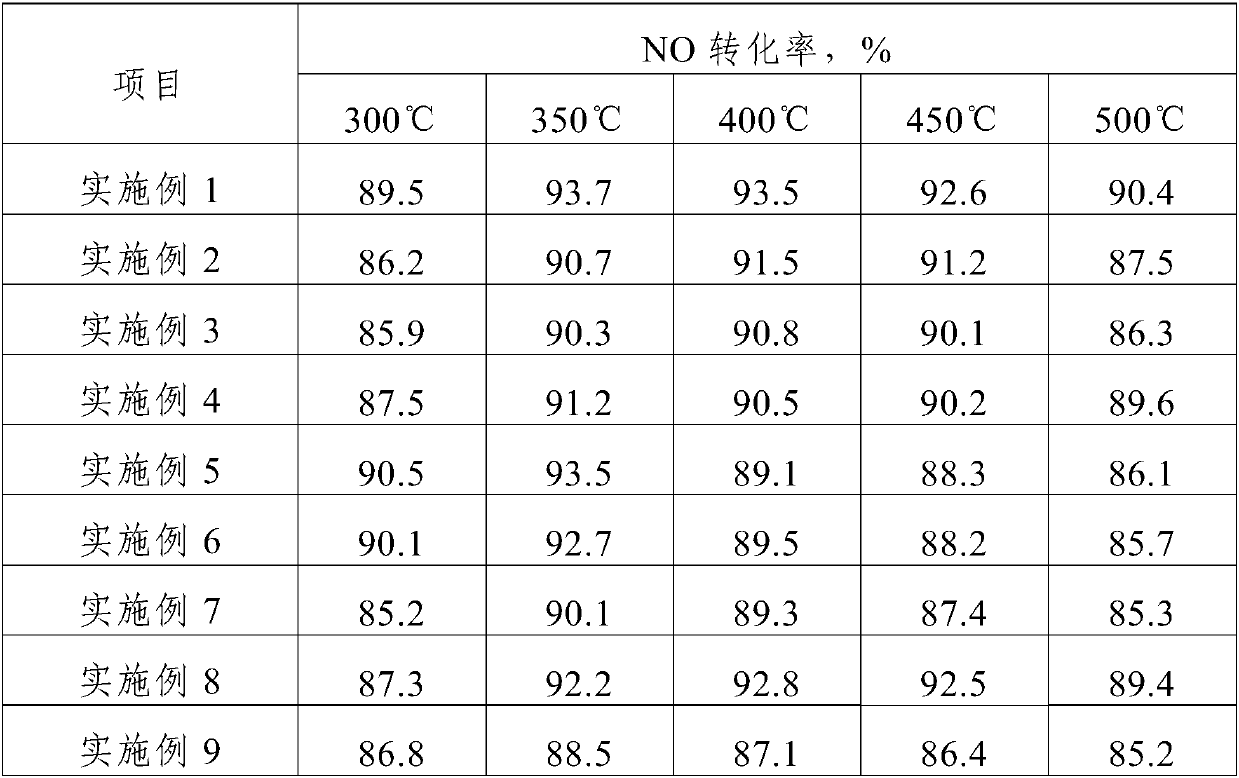

Preparation method of supported medium and high temperature denitration catalyst

InactiveCN107754849ANot easy to pulverizeExtended service lifeMolecular sieve catalystsDispersed particle separationMolecular sieveHot Temperature

The invention discloses a preparation method of a supported medium and high temperature denitration catalyst. The method comprises the following steps: 1, dissolving a soluble active metal component precursor salt and a soluble auxiliary metal component precursor salt into deionized water to obtain a transparent impregnation solution; 2, impregnating a molecular sieve carrier for 6h-24h, filtering, drying at temperature of 80-120 DEG C for 12h-24h to obtain a catalyst precursor; 3, putting the catalyst precursor in a heat treatment furnace, heating to 300 DEG C-400 DEG C, calcining while introduction of air for 1h-3h, heating up to 600-800 DEG C, calcining for 2h-6h, and cooling to obtain the supported medium and high temperature catalyst. The supported medium and high temperature denitration catalyst prepared by the method has high strength, is not easy to pulverize, has long service life, and has low catalyst bulk density. The catalyst has a NO conversion rate of 85% or more at a suitable application temperature of 300 to 500 DEG C.

Owner:XIAN ORIGIN CHEM TECH

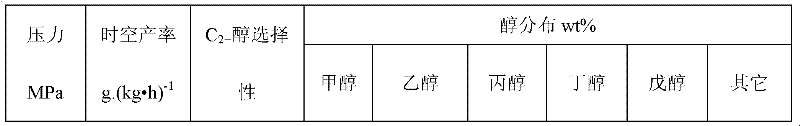

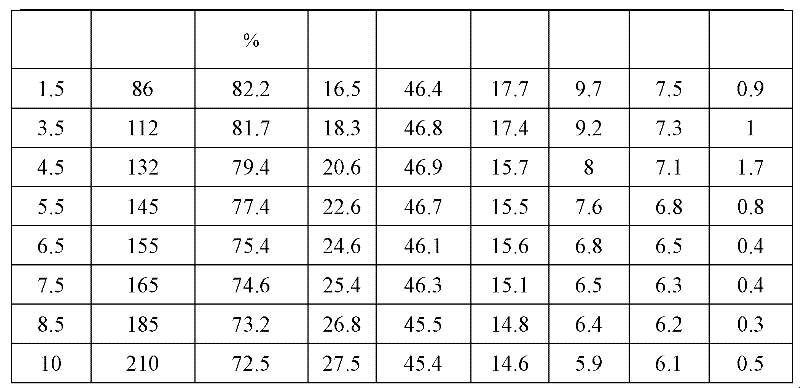

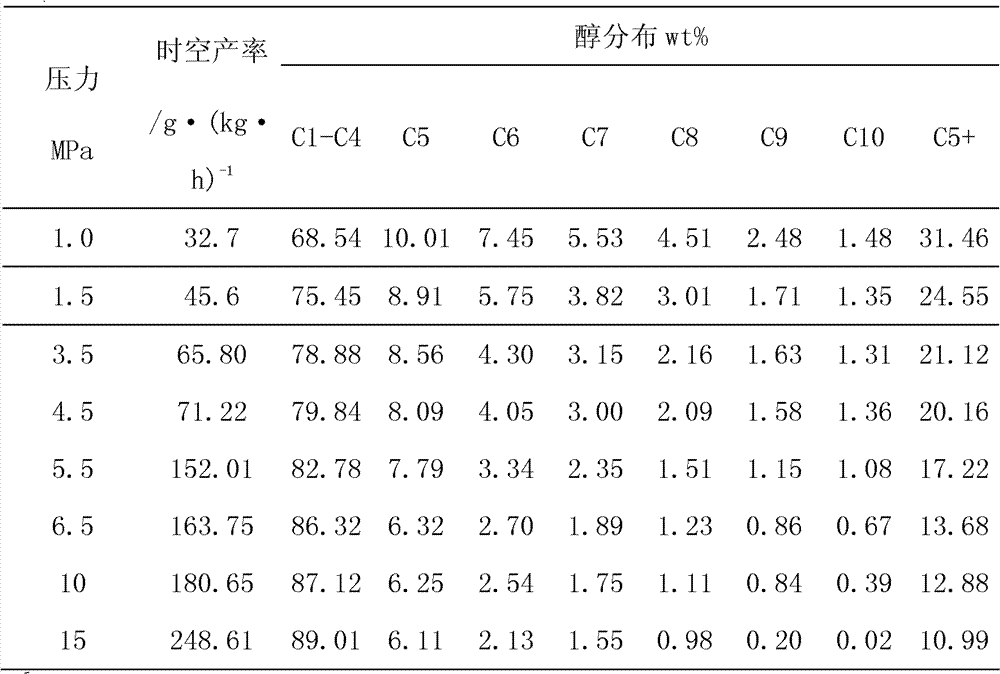

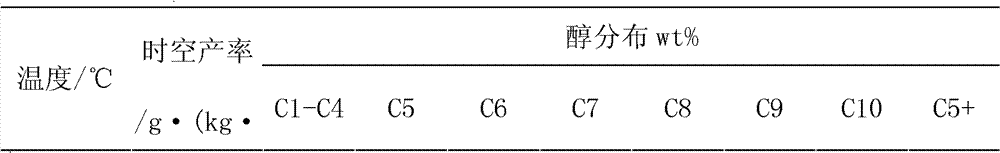

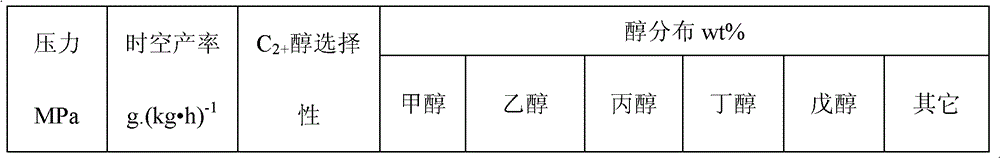

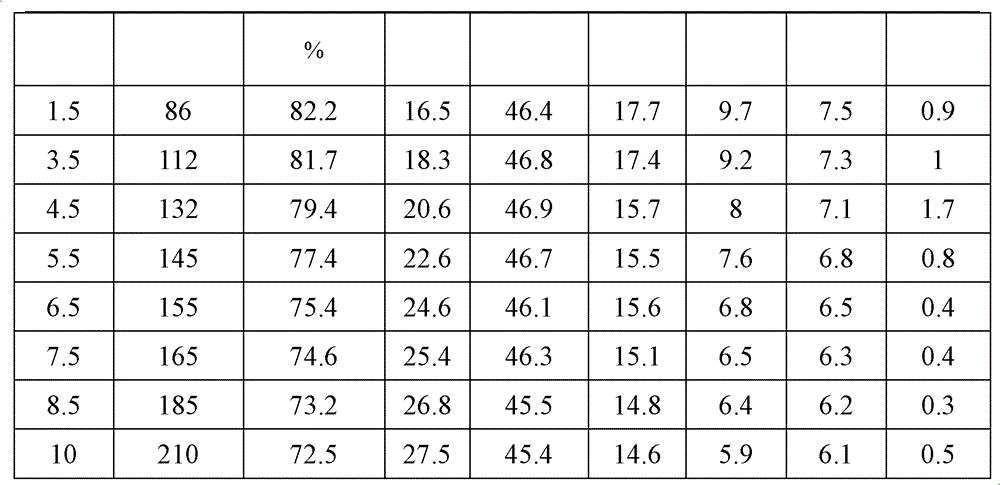

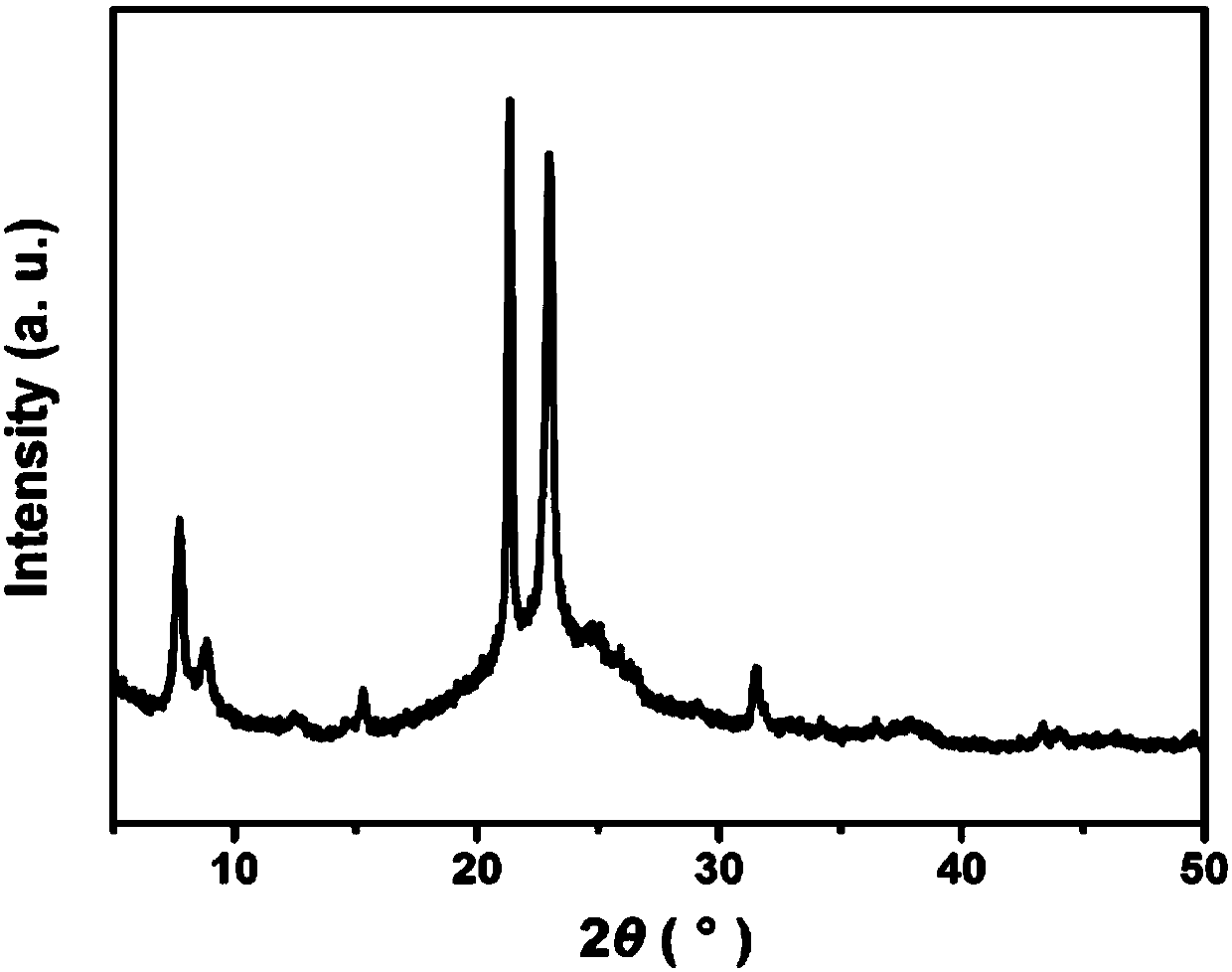

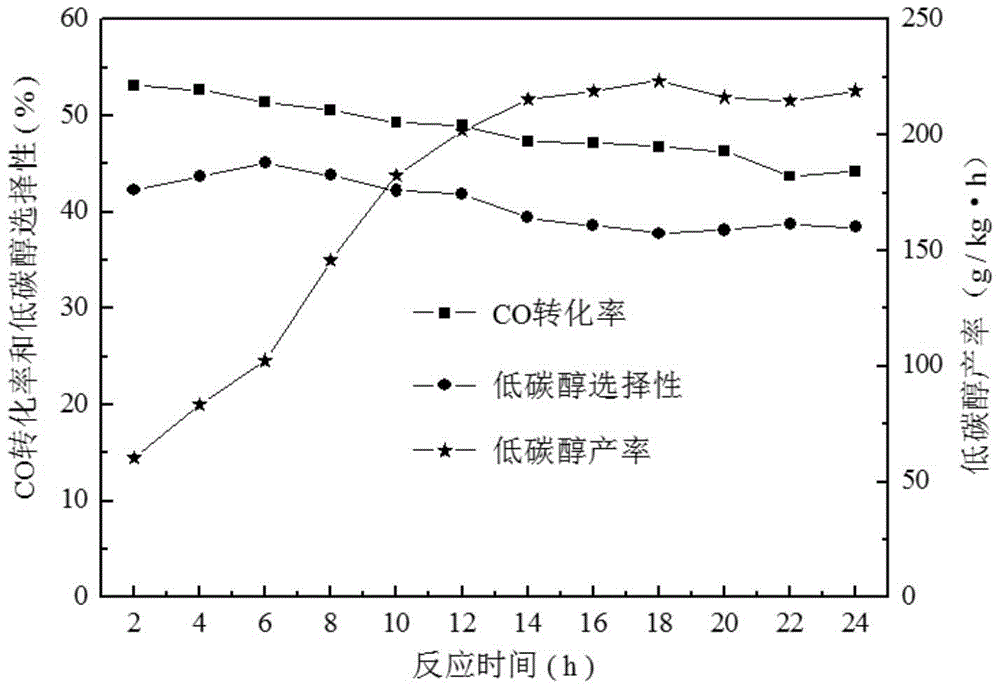

Application of Cu-Fe-based catalyst in synthesis of higher alcohol with synthetic gas

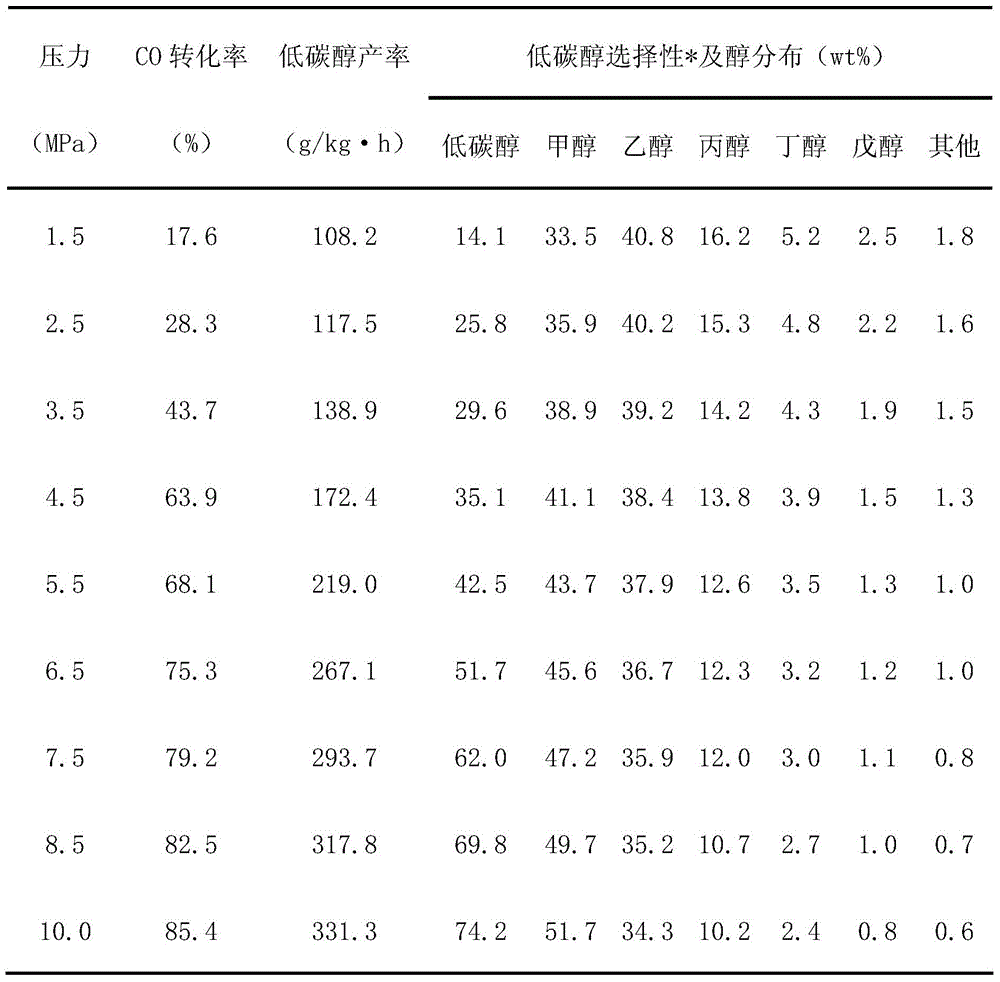

ActiveCN102319575BHighly active ingredientsHigh selectivityOrganic compound preparationHydroxy compound preparationAlkaline earth metalPtru catalyst

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

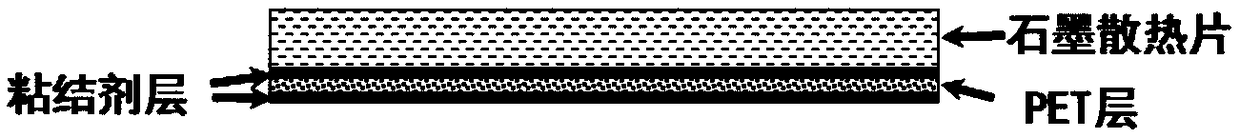

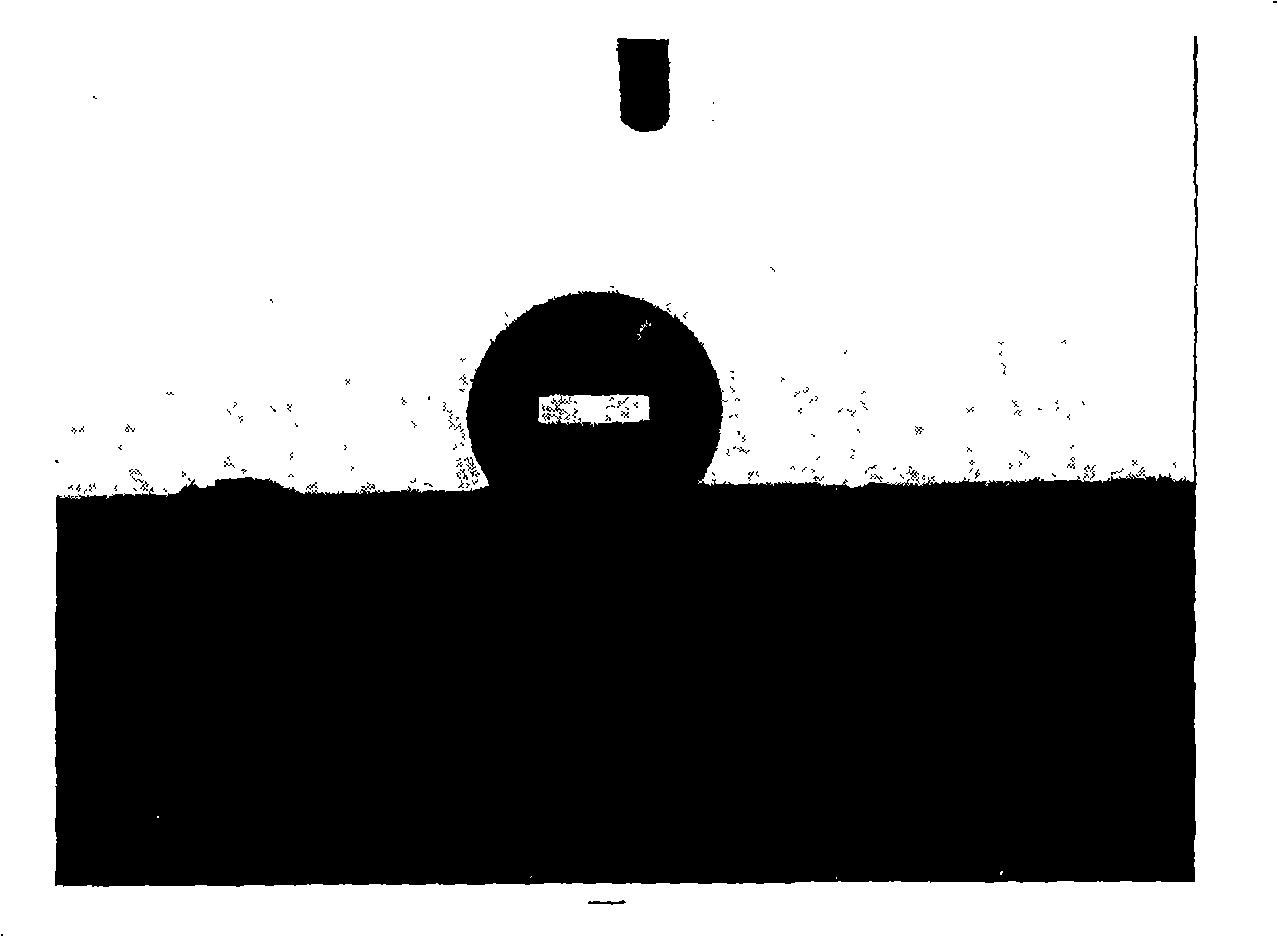

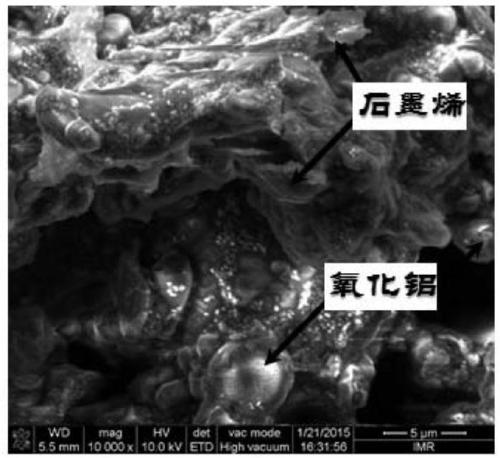

Heat-conducting adhesive containing graphene as well as preparation method and application of heat-conducting adhesive

InactiveCN109439236ASimple preparation processGive full play to thermal conductivityNon-macromolecular adhesive additivesAcrylic resinHeat conducting

The invention discloses a heat-conducting adhesive containing graphene as well as a preparation method and an application of the heat-conducting adhesive, and belongs to the technical field of new materials and applications of the new materials. The graphene composite heat-conducting adhesive material is prepared from graphene and conventional packing used cooperatively as heat-conducting packingas well as acrylic resin and other auxiliaries as a matrix with a simple process. Graphene and the conventional packing in the composite material are uniformly dispersed, the characteristics of high heat conductivity of graphene and massive filling capacity of the conventional packing are fully played, the prepared heat-conducting adhesive has properties remarkably better than those of a traditional heat-conducting adhesive, and heat-dissipating and cooling effects of electronic devices can be remarkably improved. The graphene composite heat-conducting adhesive adopts a simple process, can realize large-scale industrial production and can be taken as a novel efficient heat-conducting interface material to be applied to heat dissipation of electronic equipment independently or by cooperation with the base.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Modification method for silicon dioxide aerogel

The invention relates to a method for modifying silicon dioxide aerogel. The method of the invention is characterized in that the nature of the azeotropy of C4 to C10 aliphatic alcohols and water under the constant temperature is utilized for removing free water in the silicon dioxide wet gel; the esterification reaction of alcohol and hydroxyl on the surface of silicon dioxide is utilized for the surface finishing and modification of the silicon dioxide aerogel so as to obtain water repellent products; wherein, the mass ratio of the silicon dioxide, the water, the a lcohol and a catalyst is 1: (8.0 to 9.5): (10 to 20): (0.01 to 0.05) and the catalyst is alkyl-sulfuric acid, alkyl sulfate or alkyl sulphate ion, aryl sulfonic acid, aryl-sulphonate or aryl-sulphonate ion. The invention also relates to the silicon dioxide aerogel obtained by the method and the surface of the silicon dioxide aerogel is dehydrated and contains aliphatic groups.

Owner:BEIJING HUACONG TRADE

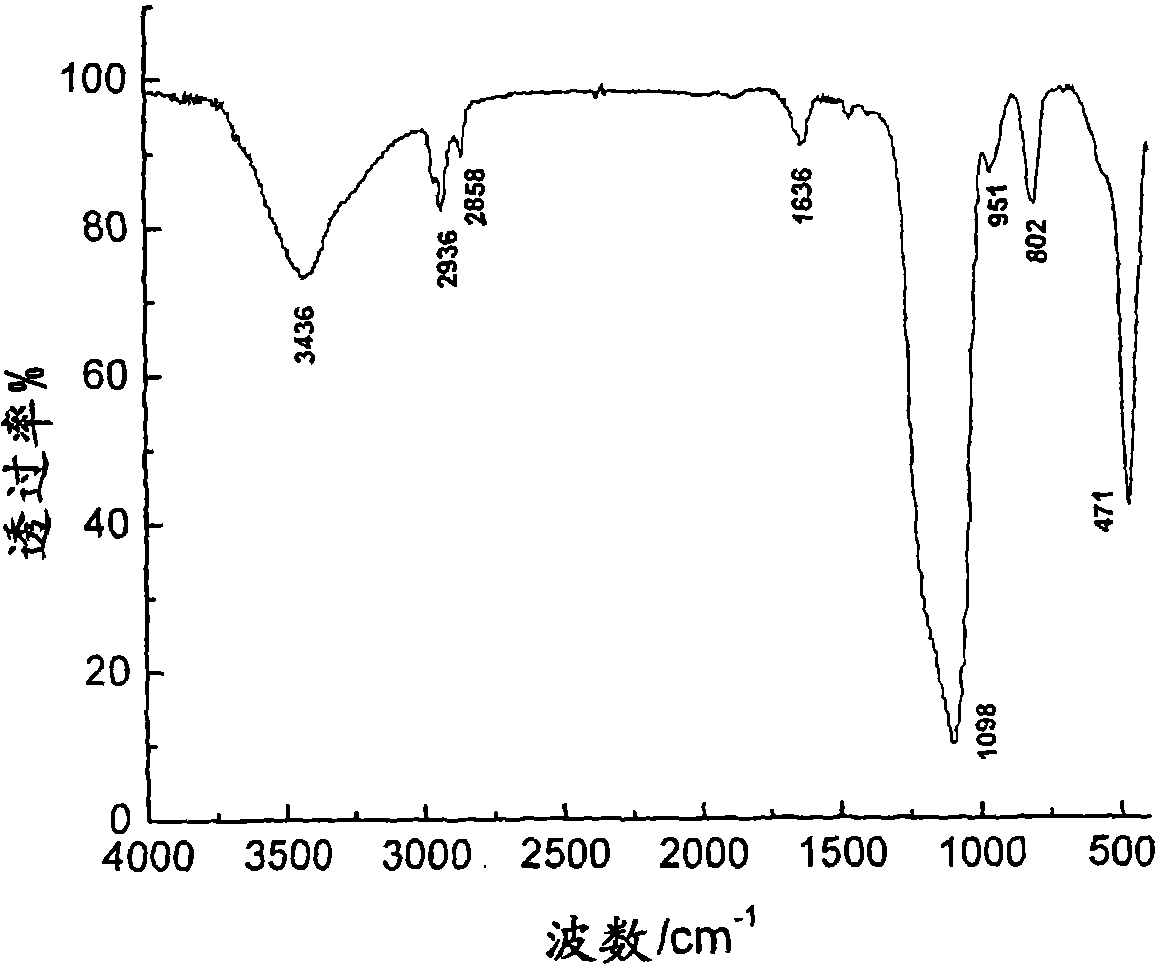

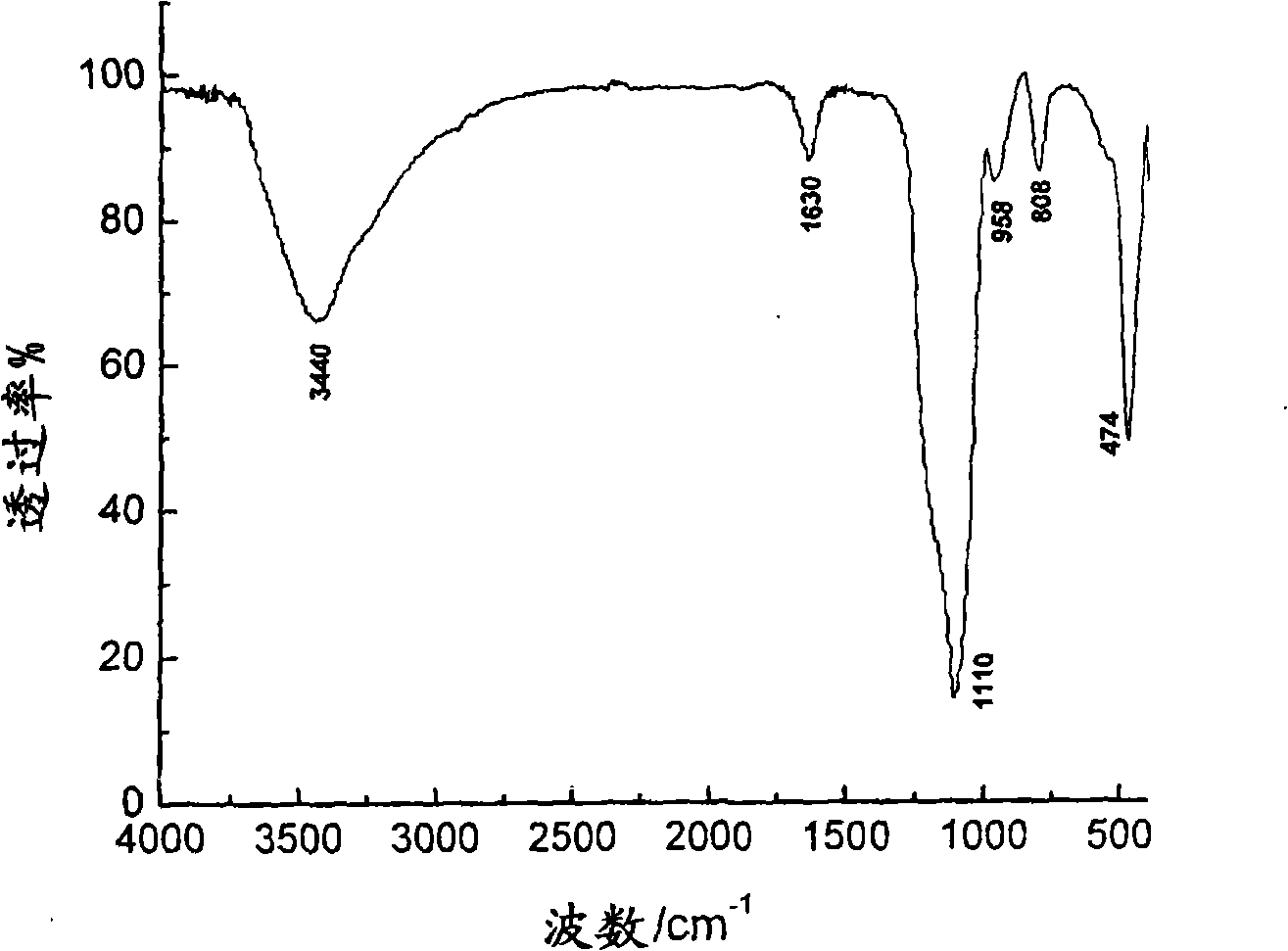

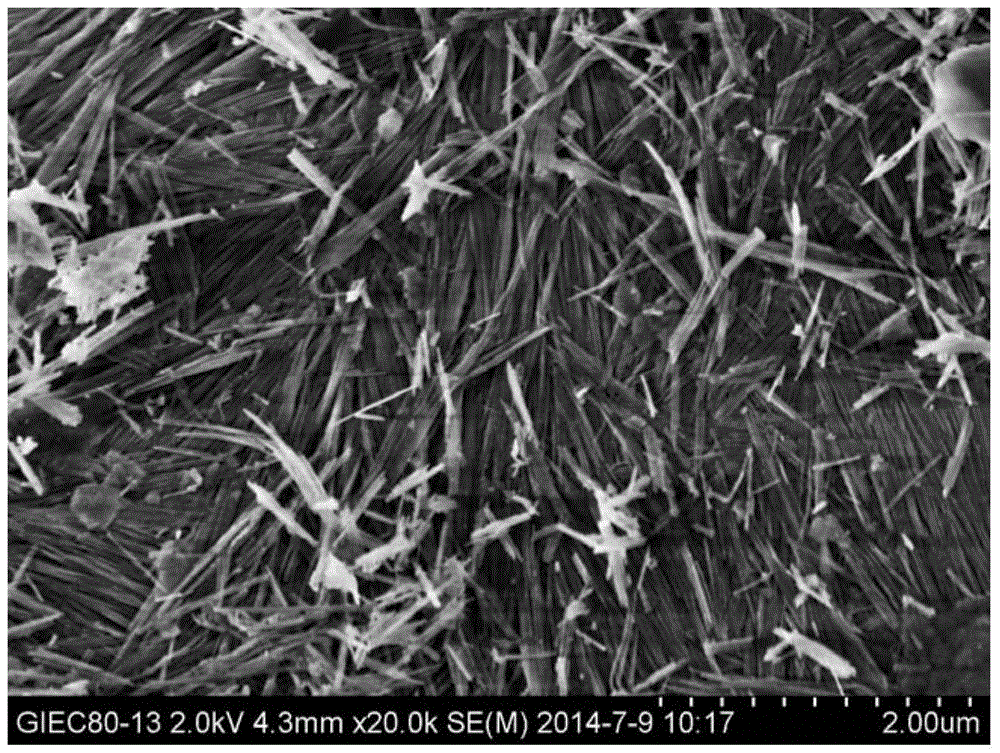

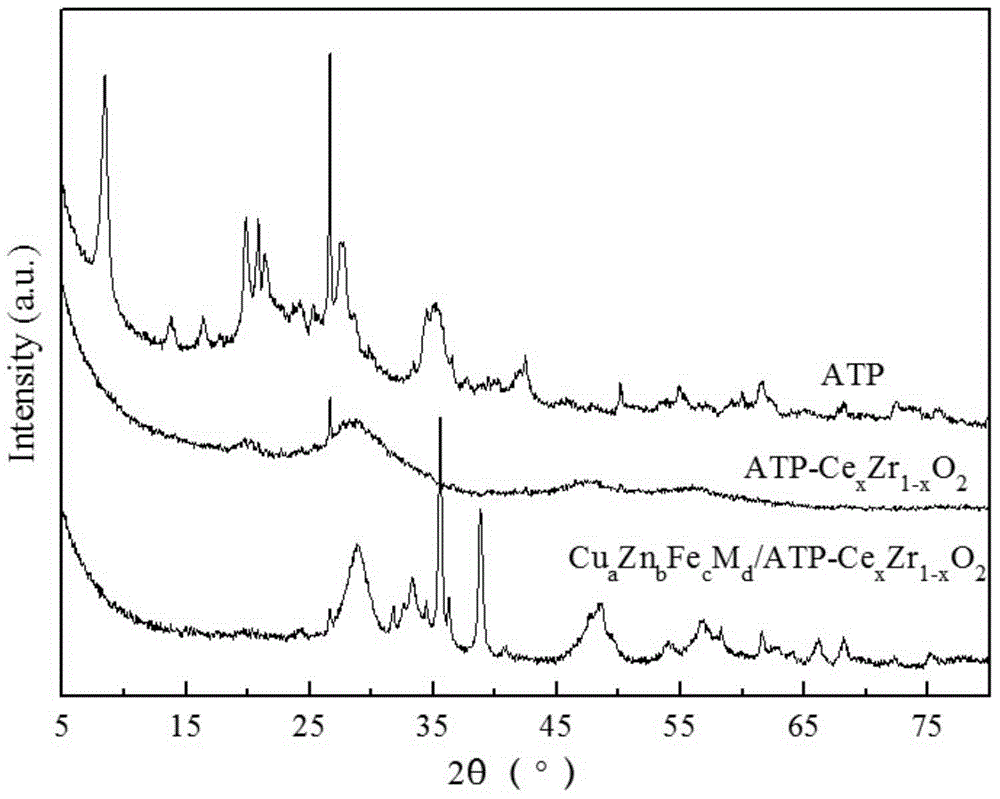

Attapulgite-based composite material loaded Cu-Zn-Fe based catalyst, preparation method and applications thereof

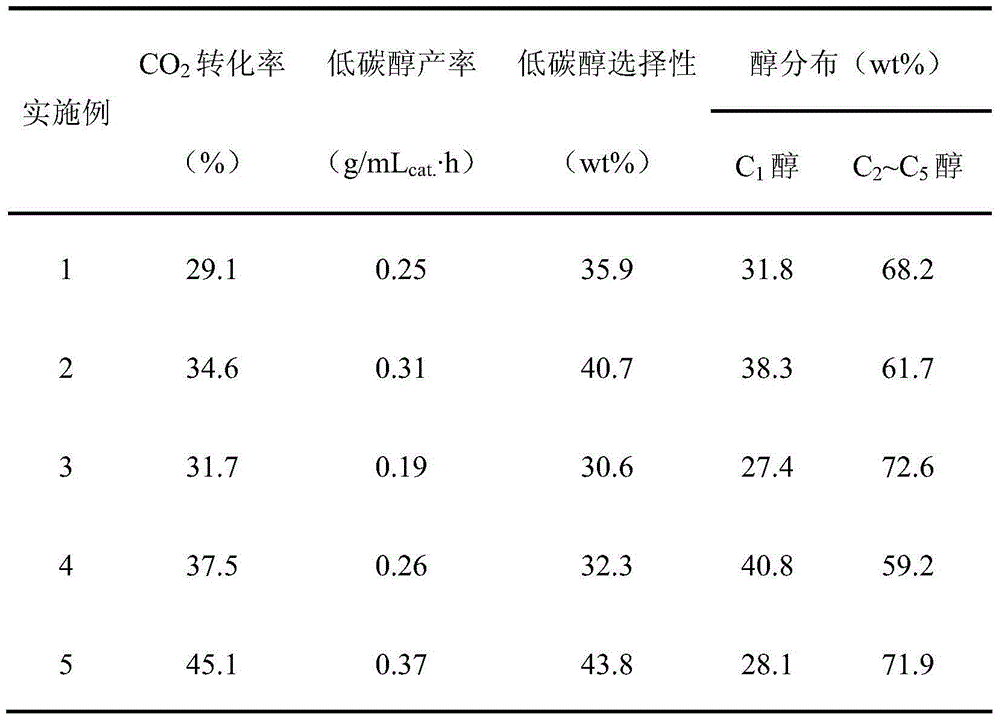

ActiveCN104815664AImprove structural performanceReduce dosageOrganic compound preparationHydroxy compound preparationCeriumIndustrial scale

The present invention provides an attapulgite / cerium-zirconium solid solution composite material loaded Cu-Zn-Fe-based catalyst, a preparation method and applications of the catalyst in preparation of C1-C5 low carbon alcohols through CO2 hydrogenation. According to the present invention, the catalyst adopts an attapulgite / cerium-zirconium solid solution composite material as a carrier, and the attapulgite / cerium-zirconium solid solution composite material preparation method comprises: carrying out pressurization acid activation to prepare acid-modified attapulgite, and then adopting a co-current flow co-precipitation method to obtain the attapulgite / cerium-zirconium solid solution composite material, wherein the total loading amount of the catalysis activity component is 25-80 wt%, and the catalyst carrier accounts for 20-75 wt%; and the catalyst uses the composite material formed from the natural nanometer material attapulgite doped cerium-zirconium solid solution having characteristics of rich resource and low price as the carrier, the cost is low, and the preparation method is simple, is easily subjected to industrial scale production, and is suitable for high-value conversion of bio-butanol fermentation exhaust gas and other low H / C ratio raw gases.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Safe and environment-friendly type abrasion-resistant self-cleaning latex paint and preparation method thereof

InactiveCN106883688ALower minimum film forming temperatureLow film forming temperatureAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceCellulose

The invention relates to a safe and environment-friendly type abrasion-resistant self-cleaning latex paint and a preparation method thereof. The latex paint is prepared from the following components in parts by weight: 390 to 420 parts of emulsion, 20 to 30 parts of film forming additive, 5 to 50 parts of silicon sol, 2 to 4 parts of multifunctional ammine additive, 5 to 10 parts of hydrophobic agent, 2 to 5 parts of wetting agent, 7 to 8 parts of dispersant, 2 to 5 parts of defoaming agent, 1 to 3 parts of cellulose, 2 to 4 parts of thickener, 240 to 260 parts of inorganic filler, 250 to 270 parts of water, 2 to 4 parts of preservative, 1 to 2 parts of anti-mildewing agent and 15 to 20 parts of propylene glycol. Compared with the prior art, the latex paint has the advantages that the compactness of a paint film is good, the hardness is high, the abrasion-resistant property is good, static electricity is not produced, and various dust in air is difficult to adhere; the preparation method is simple, the controllability is good, the green and environment-friendly effect is achieved, the technical defect of poor dirt resistance in a latex paint is effectively overcome, the service life of the latex paint is prolonged, the economy is good, the industrialized expanding production is easy, and the application prospect is good.

Owner:BNSA NEW MATERIAL SHANGHAI CO LTD

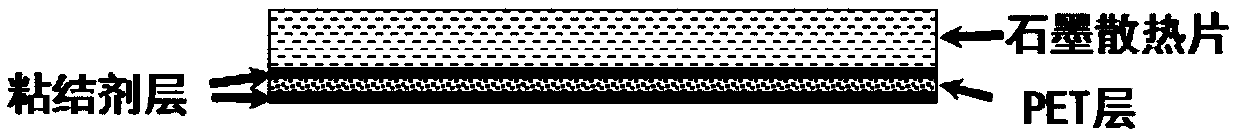

Heat conductive interface material for heat dissipation of electronic equipment

PendingCN109553908ASimple preparation processLower interface thermal resistanceHeat-exchange elementsGrapheneAcrylic resin

The invention discloses a heat conductive interface material for heat dissipation of electronic equipment and belongs to the technical field of new materials. Through simple process, graphene and common filler are cooperated to form heat conductive filler; then with acrylic resin and other additives being a substrate, a graphene composite heat conductive adhesive material is prepared and serves asthe heat conductive interface material. In the heat conductive interface material, the graphene and the common filler are uniformly dispersed, so that the characters that the graphene has high heat conductivity and the common filler achieves large filling quantity are fully achieved, and the performances of the heat conductive adhesive are better than those of a conventional heat conductive adhesive. The product significantly improves heat dissipation and cooling effect on electronic devices. The graphene composite heat conductive adhesive is simple in preparation method and allows large-scale industrial production, and can be applied independently or matched with a substrate as a novel high-effective heat conductive interface material for heat dissipation of electronic equipment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for synthesizing 2,2,4-trimethyl-1,2-dihydroquinoline and polymer thereof using microchannel reactor

ActiveCN103694169BShort reaction timeEasy for industrial scale-up productionOrganic chemistryHeat carrierChemical reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

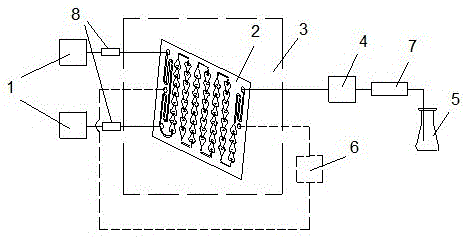

Method for synthesis of 2,2,4-trimethyl-1,2-dihydroquinoline and polymer thereof by utilizing microchannel reactors

ActiveCN103694169AShort reaction timeEasy for industrial scale-up productionOrganic chemistryHeat carrierChemical reaction

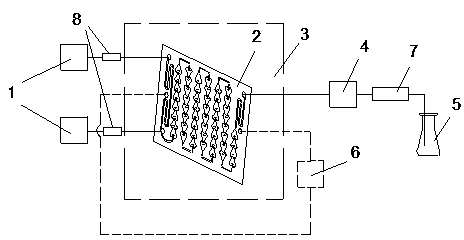

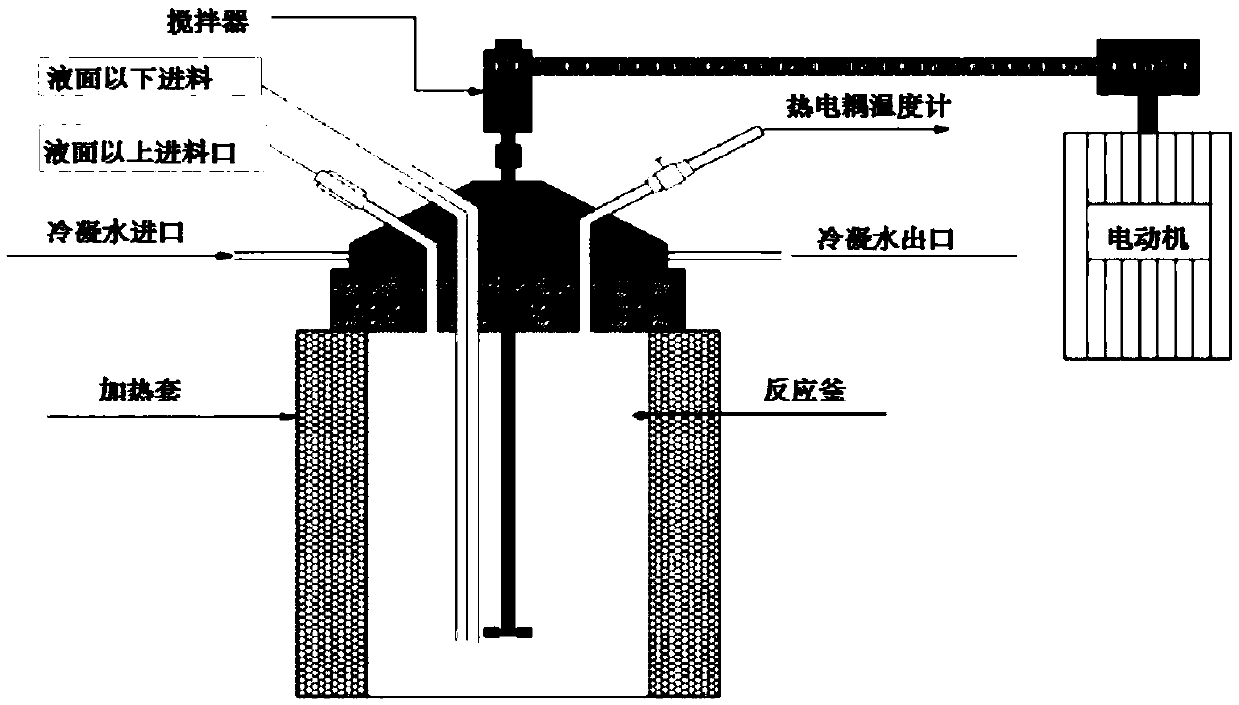

The invention relates to a method for synthesis of 2,2,4-trimethyl-1,2-dihydroquinoline and a polymer thereof by high-throughput microchannel reactors. A mixture of acetone and aniline hydrochloride is used as a starting reaction raw material and is injected into a microchannel reactor system for reaction, wherein the microchannel reactor system is composed of 1-10 pieces of microchannel reactors which are connected together in series and can be used for continuous flowing, the single-piece reactors are connected together in series by microchannels having the shape similar to a heart shape, and the liquid holdup amount is 8-10 ml; and a continuous flowing reaction is carried out. Through a heat carrier circulation system, the reaction temperature is set to 90-120 DEG C, the pressure is set to 0-10 bar, and the reaction standing time is set to 20-200 s; the obtained solution is cooled by a condenser and is collected, unreacted acetone is removed by distillation, and the target product is obtained. The preparation method provided by the invention has the advantages of continuous reaction performing, short required reaction time, no amplification effect, and strong versatility, does not require to remove generated water during the reaction process, and can be applied to various liquid-liquid, gas-liquid and other chemical reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic synthesis method of N-substituted ethanol amine compound

InactiveCN105503616AEasy to makeLarge specific surface areaMolecular sieve catalystsAmino compound preparation by condensation/addition reactionsSynthesis methodsReaction temperature

The invention provides a catalytic synthesis method of an N-substituted ethanol amine compound. The synthesis method includes the steps that an epoxy compound shown by the formula (II) (please see the specification), an amine compound shown by the formula (III) (please see the specification) and a metal-heteroatom-modified MCM-41 molecular-sieve-mesoporous catalyst are mixed and reacted for 40-100 min under the condition that the reaction temperature ranges from 60 DEG C to 190 DEG C, and the reaction pressure ranges from 1 MPa to 3.5 MPa, the catalyst in the reaction liquid is filtered out, and the N-substituted ethanol amine compound is obtained. According to the catalytic synthesis method, the catalyst is easy to prepare, large in specific surface area and long in service life, has abundant acidity active sites, and has the quite good catalytic performance in the process of synthesizing N-substituted ethanol amine through amine and an epoxy compound with the liquid phase method; the conversion rate of the amine is high, the selectivity of the N-substituted ethanol amine is good, the reaction condition is mild, and industry enlargement production is facilitated.

Owner:ZHEJIANG UNIV OF TECH

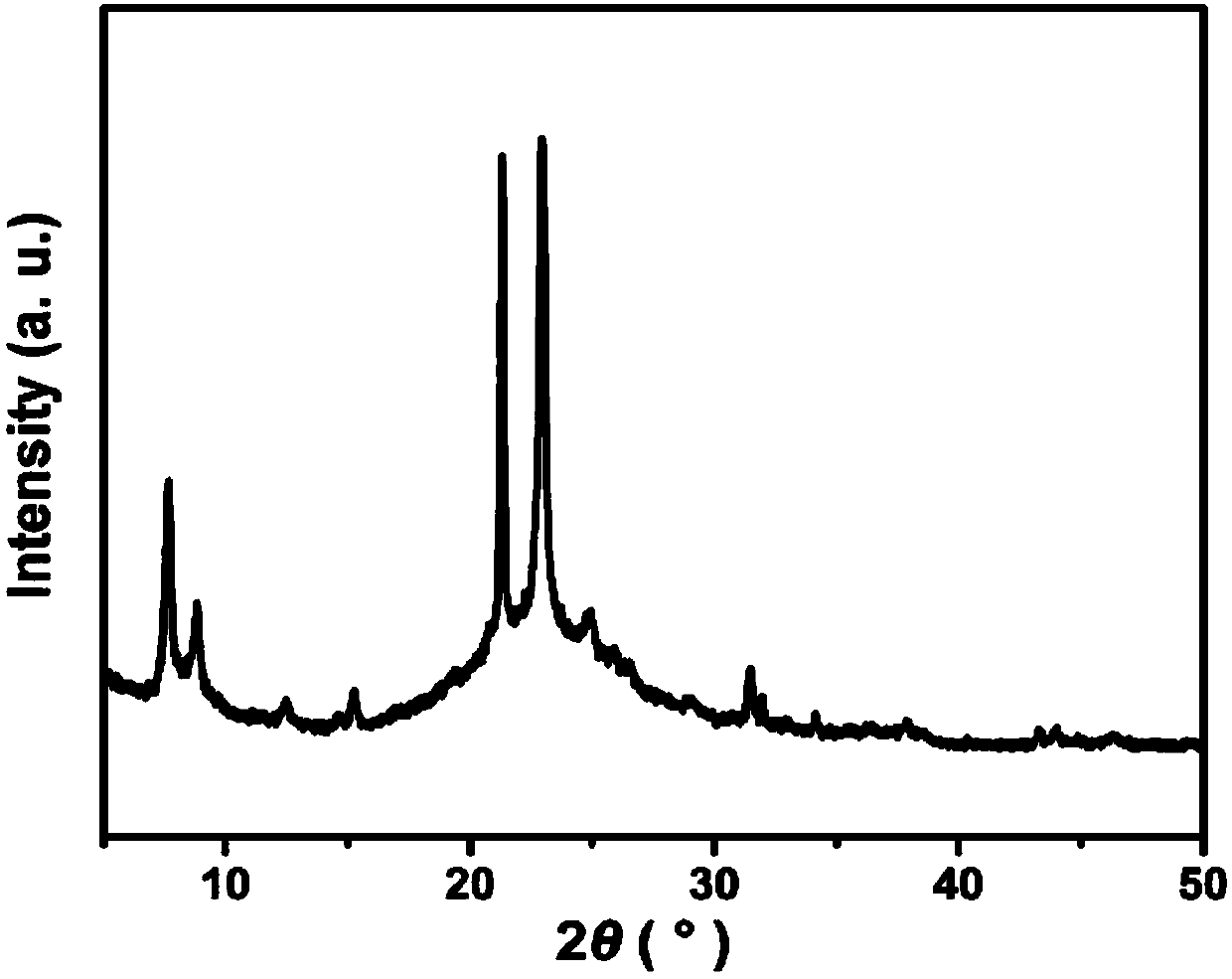

Cu-Fe-Co base catalyst used for synthesizing low carbon alcohol by utilizing synthesis gas as well as preparation method and application thereof in low carbon alcohol synthesizing process by virtue of synthesis gas

ActiveCN102247852BLow costEasy to prepareOrganic compound preparationHydroxy compound preparationRare-earth elementAlkaline earth metal

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Low Si/Al ratio ZSM-48 molecular sieve preparation method

ActiveCN110127719AIncrease acidityHigh densityMolecular-sieve and base-exchange compoundsBulk chemical productionMolecular sieveHalogen

The invention discloses a low Si / Al ratio ZSM-48 molecular sieve preparation method, which comprises: (1) treating raw materials to obtain a precursor gel; (2) carrying out hydrothermal crystallization on the precursor gel to obtain a sample; and (3) treating the sample to obtain a ZSM-48 molecular sieve, wherein the raw materials comprise a silicon source, an alkali source, a structure-directingagent (SDA), an aluminum source, an acid and water, the structure-directing agent has a structure represented by a formula I (CH3)3N<+>RX (formula I), R is C2-6 alkenyl or C2-5 alkyl, and X is selected from halogen or hydroxyl.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of vegetable oil degummed zeolite

InactiveCN106281669AImprove adsorption capacityAbundant resourcesFatty-oils/fats refiningWater bathsVegetable oil

The invention relates to a preparation method of vegetable oil degummed zeolite. The method is characterized in that the vegetable oil degummed zeolite is prepared with zeolite and one or more of phosphoric acid, citric acid, oxalic acid and tartaric acid as the raw materials, the method includes the specific steps of firstly, mixing zeolite with granularity of 100 mesh to 400 mesh with a water solution of one or more of phosphoric acid, citric acid, oxalic acid and tartaric acid with mass being 0.25-5 times that of zeolite and mass concentration being 5-40% to prepare a suspension, and conducting water bath for 1-4 h at the stirring revolution of 100-500 r / min in a water bath pot at 40-70 DEG C; secondly, putting soaked zeolite in an air dry oven to be dried for 1-5 h at 40-100 DEG C, taking out zeolite, putting the zeolite in a drying vessel to be cooled, and smashing the zeolite into 200 mesh to prepare the vegetable oil degummed zeolite. Non-hydratable phospholipids in vegetable oil can be converted into hydratable phospholipids through the degummed zeolite, and the zeolite has good adsorption capacity for hydratable phospholipids and can effectively remove phospholipids and other colloidal substances in vegetable oil.

Owner:YUNNAN NORMAL UNIV

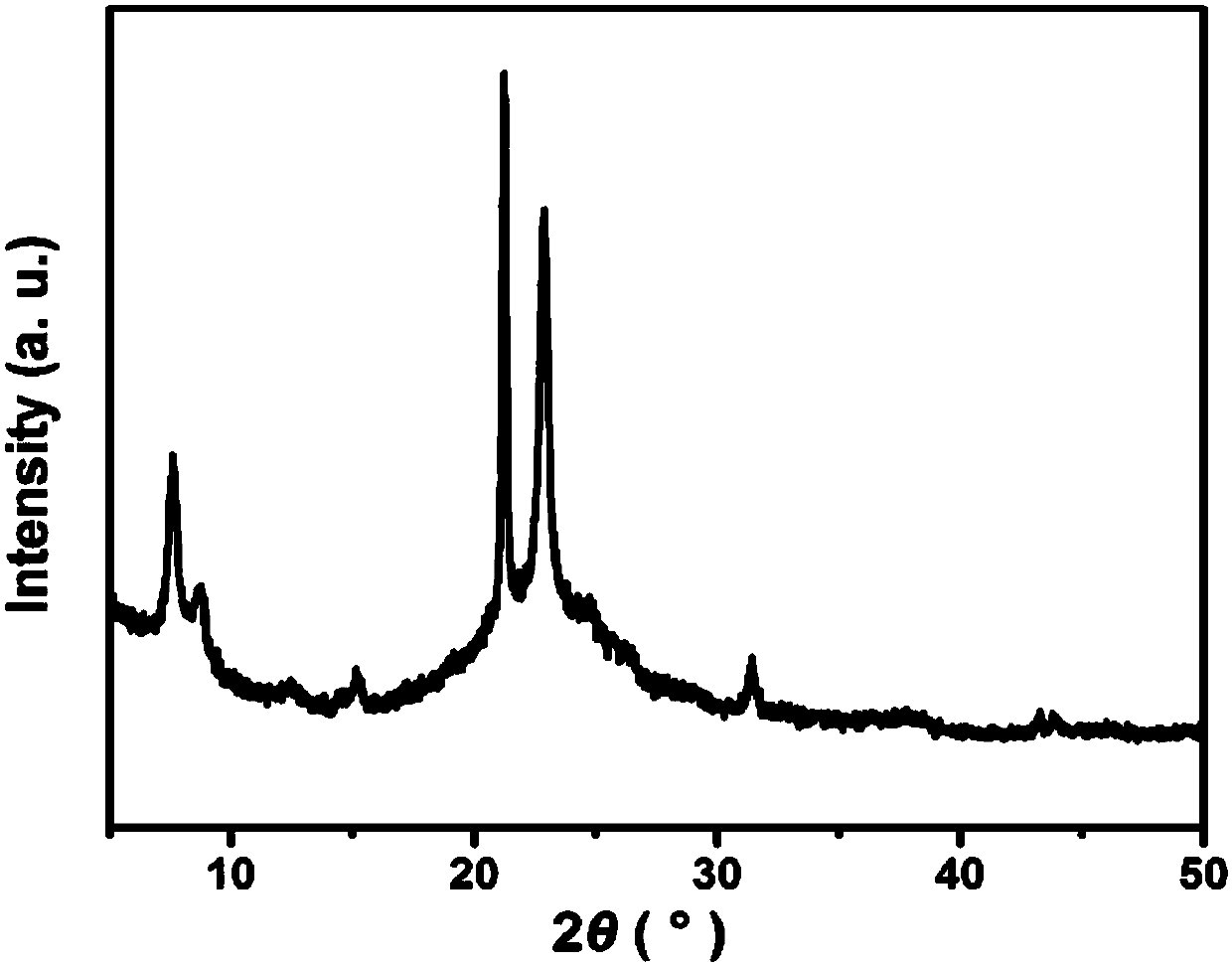

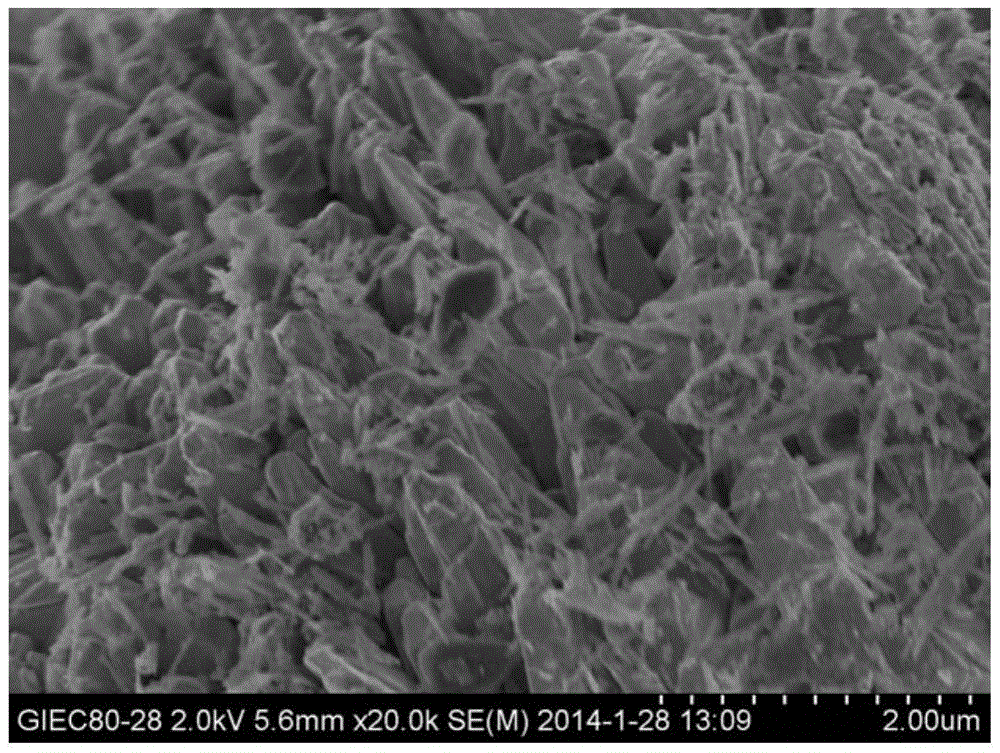

Natural nanomaterial attapulgite-supported cu-fe-based multi-component catalyst and its preparation method and application in the synthesis of low-carbon alcohols

ActiveCN104084212BHigh activityGood choiceOrganic compound preparationHydroxy compound preparationRare-earth elementAlcohol

The invention provides a natural nano-material attapulgite-supported Cu-Fe-based multi-component catalyst, a preparation method thereof and an application in the synthesis of low-carbon alcohols. Its expression is Cu a Fe b m c / ATP; Wherein the auxiliary agent M is a combination of one or more elements in transition metal elements, alkali metals or rare earth elements; the Cu, Fe and M supported in the catalyst account for the total amount of the catalyst respectively a, b and c, and a=10-35%, b=10-25%, c=1-10%, and the rest is catalyst carrier ATP. The acid-modified attapulgite with a large specific surface area was prepared by modifying the natural attapulgite raw material with inorganic acid, and then used as a carrier, which was prepared by impregnation in a mixed aqueous solution of metal salts of Cu, Fe and other components. have to. The attapulgite-supported Cu-Fe-based multi-component catalyst of the present invention can be used in the process of synthesizing low-carbon alcohol from syngas. Attapulgite, a natural nanometer material with abundant resources and low price in my country, is used as a carrier, and has low cost, simple preparation method, stable performance, and easy industrial scale-up production.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Amorphous alloy catalyst for hydrogenating cyclobufene sultone and its prepn. and application

InactiveCN1128015CNo pollution in the processHigh low temperature activityPhysical/chemical process catalystsOrganic chemistryPtru catalystMetallurgy

Owner:NANKAI UNIV

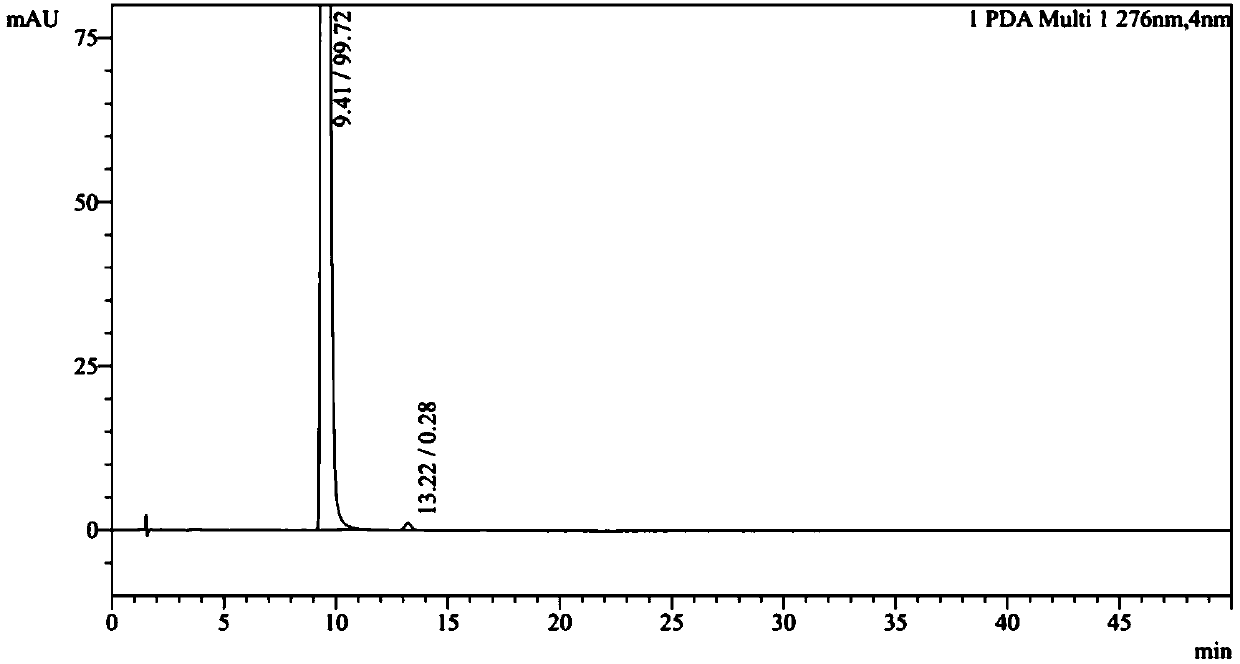

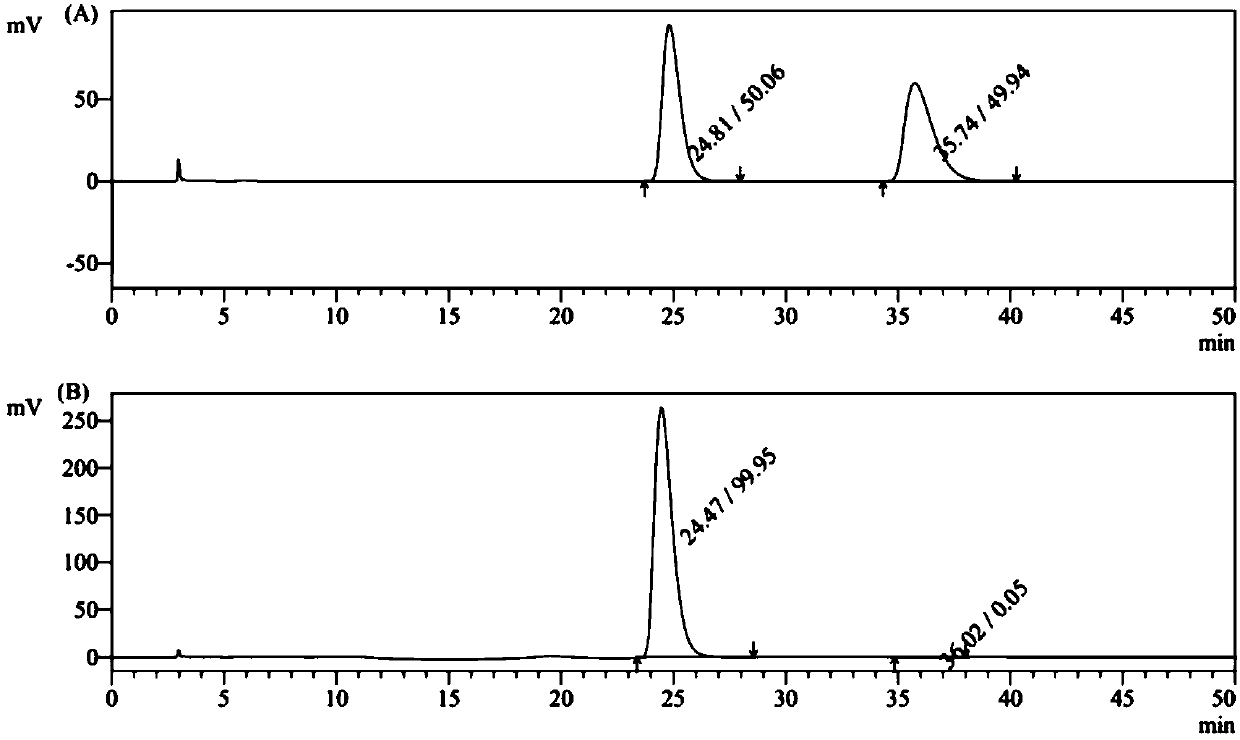

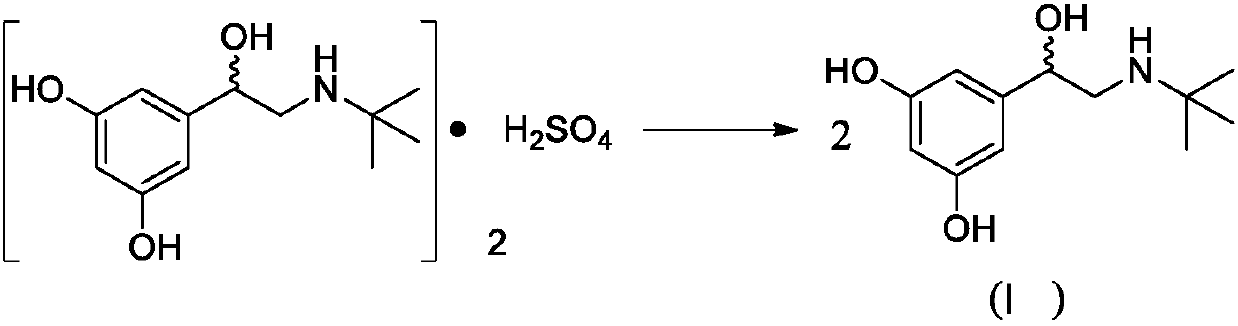

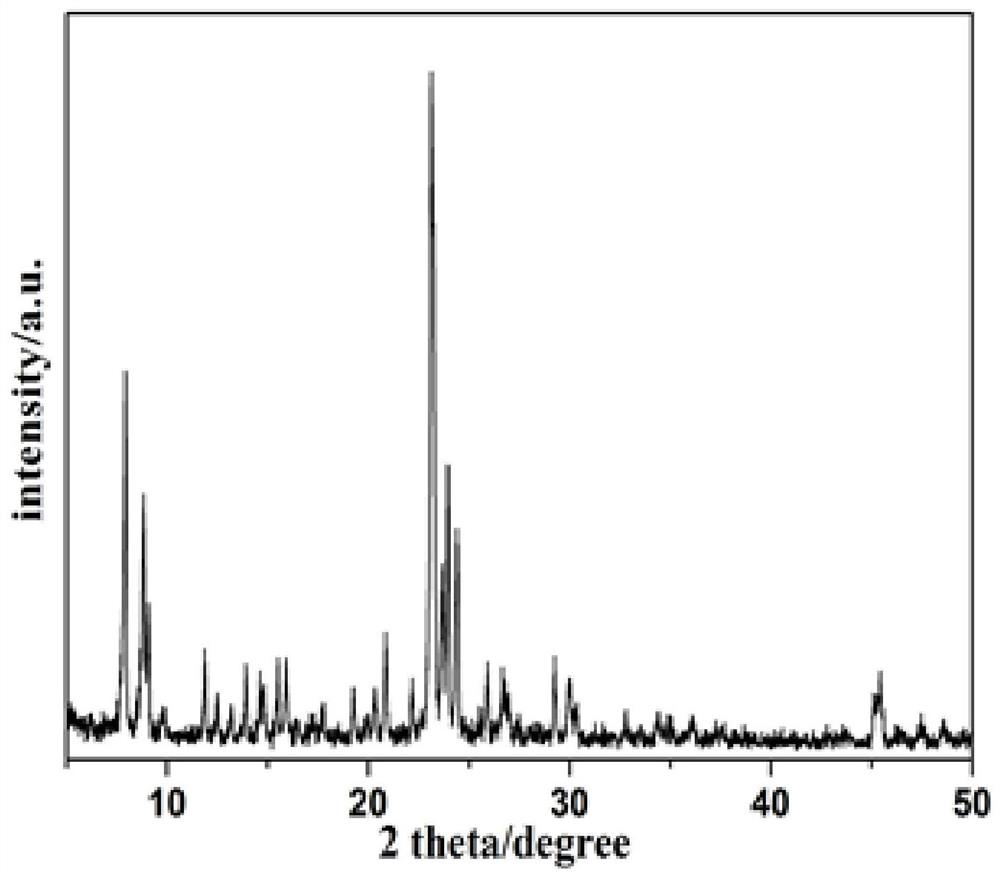

Preparation method and anti-asthma application of levo(-)terbutaline

PendingCN110156614AReduce generationEasy to operateOrganic active ingredientsOrganic compound preparationDiseaseObstructive Pulmonary Diseases

The invention relates to a preparation method of high optical purity and high chemical purity levo(-)terbutaline. The method provided by the invention has the advantages of cheap and easily availablebulk drugs, simple operation and short reaction period, is suitable for industrial production, improves the total yield, and at the same time can acquire high optical purity and high chemical purity product. The high optical purity and high chemical purity levo(-)terbutaline provided by the invention is applied to drug efficacy study of resistance to asthma and obstructive pulmonary disease. The result indicates that compared with the commercially available despinners, the levo(-)terbutaline can improve the anti-asthma efficacy manyfold, and proves a new obtains products with high chemicalpurity and optical purity. The anti-asthma and pulmonary obstruction effects of levo-terbutaline with high optical purity and high chemical purity in the present invention were studied. The results show that levoterbutaline in the invention can double the antiasthmatic efficacy compared with racemates sold in the market, and provides a new optimal treatment scheme for asthma related diseases.

Owner:KEY PHARMA BIOMEDICAL INC

Synthesis method of MFI molecular sieve nanosheet

PendingCN112624145ASolve the problem of high synthesis temperatureSynthetic safetySilicaNanotechnologyMolecular sieveFiltration

The invention discloses a synthesis method of an MFI molecular sieve nanosheet. The method takes a small amount of template agent, silicon source and aluminum source as raw materials for hydrothermal synthesis, and is characterized by comprising the following steps: firstly, uniformly stirring the template agent, the silicon source and a certain amount of water, then selectively adding the aluminum source, adjusting the pH value of the system, stirring and pre-crystallizing for 1-50 hours at 40-100 DEG C, and then crystallizing for 1-10 days at 80-150 DEG C; and after the crystallization is finished, cooling the reaction kettle to room temperature, and then carrying out suction filtration / centrifugation, washing and drying on the product. According to the method, the synthesis temperature is low, the synthesis pressure is low, a fluorine-containing reagent does not need to be used, the yield exceeds 80%, and the thickness of the nanosheet can be regulated and controlled through the pH value of the system and the dosage of a template agent. The synthesized MFI molecular sieve nanosheet is high in crystallinity and controllable in thickness, more synthesis energy consumption is saved under the low-temperature and low-pressure conditions, industrial scale-up production is facilitated, and the MFI molecular sieve nanosheet has a good industrial popularization prospect.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com