Nanometer needle-shaped SAPO-34 molecular sieve, as well as preparation and application thereof

A SAPO-34, nanoneedle technology, applied in molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, nanotechnology and other directions, can solve problems such as difficult application, reporting, environmental pollution, etc., and achieve large specific surface area, operation Easy, step-by-step effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

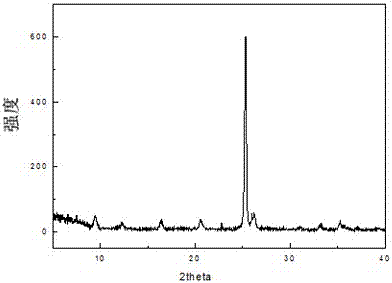

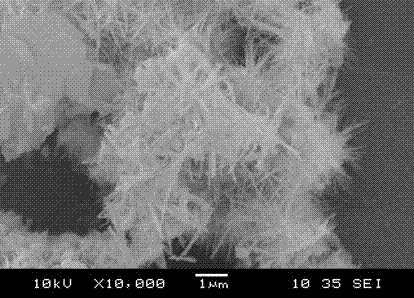

[0030] Weigh 2.04g of aluminum isopropoxide into the beaker, then add 7.2ml of deionized water into the beaker, then add 0.615ml of phosphoric acid solution, stir for 20 minutes under the condition of heating in a water bath at 35°C, then add 1.32ml of morpholine solution, After continuing to stir for 1 hour, add 0.677ml of tetraethyl orthosilicate dropwise, continue heating and stirring in a water bath for 2 hours to obtain gel A, then add 5.45ml of 40% HF acid solution dropwise, at this time, gel A decondenses into solution B, and then Stirring was continued for 2h. After the solution B obtained above was stirred, it was transferred to a reaction kettle lined with polytetrafluoroethylene. After the kettle was filled, the reaction kettle was moved into an oven for crystallization at 170° C. for 60 hours. Immediately after the crystallization was completed, the reaction kettle was taken out, and the outer wall of the reaction kettle was rinsed with tap water to make it cool ra...

Embodiment 2

[0032] Weigh 2.04g of aluminum isopropoxide into the beaker, then add 7.2ml of deionized water into the beaker, then add 0.615ml of phosphoric acid solution, stir for 20 minutes under the condition of heating in a water bath at 35°C, then add 1.32ml of morpholine solution, After continuing to stir for 2 hours, add 0.677ml of tetraethyl orthosilicate dropwise, continue heating and stirring in a water bath for 3 hours to obtain gel A, then add 5.45ml of 40% HF acid solution dropwise, at this time, gel A decondenses into solution B, and then Stirring was continued for 3h. After the solution B obtained above was stirred, it was transferred to a reaction kettle with a polytetrafluoroethylene lining. After the kettle was filled, the reaction kettle was moved into an oven, and crystallized at 200° C. for 36 hours. Immediately after the crystallization was completed, the reaction kettle was taken out, and the outer wall of the reaction kettle was rinsed with tap water to make it cool ...

Embodiment 3

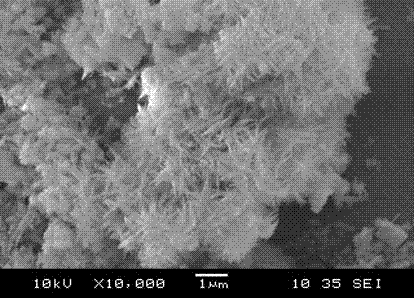

[0034] The steps in this embodiment are exactly the same as those in Embodiment 1. The difference is: the HF solution taken changed from 5.45ml to 4.35ml. The prepared samples are also nano-acicular SAPO-34 molecular sieves.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com