Method for synthesizing metal-modified SAPO-34 molecular sieve

A SAPO-34, metal modification technology, applied in the direction of molecular sieve catalysts, including molecular sieve catalysts, molecular sieves and base-exchanged phosphates, etc., can solve the problem of catalyst performance degradation, catalyst performance instability, and no mention of SAPO-34 molecular sieve hydrothermal Stability and other issues, to achieve stable performance, excellent reaction performance, good hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

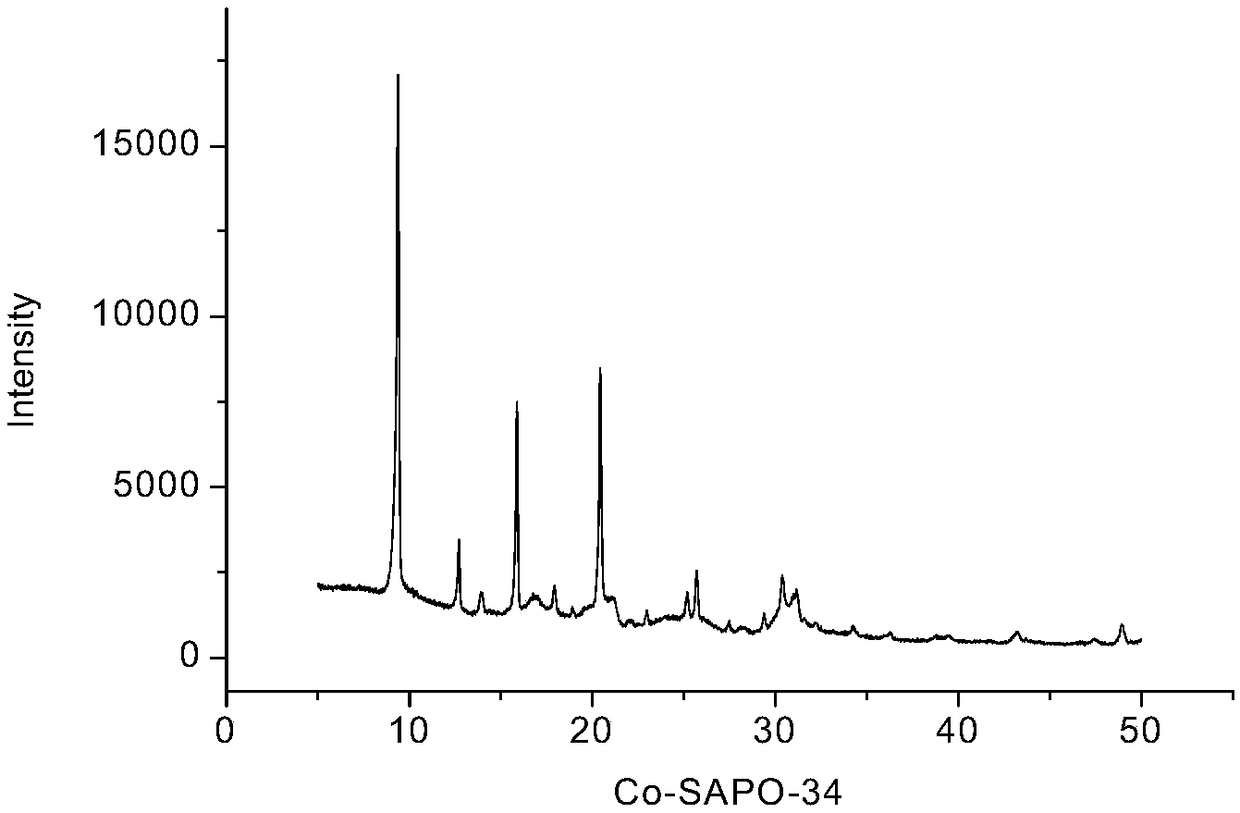

[0037] Example 1 (Co-SAPO-34)

[0038] Cobalt nitrate 80g (analytically pure) is dissolved in 100ml water and is made into solution for subsequent use, and 840g pseudo-boehmite (Al 2 o 3 67% by mass) was dissolved in 200ml of deionized water and stirred evenly, then added to the aqueous solution of cobalt nitrate, stirred at room temperature for 2 hours, filtered, washed, dried, and then calcined at 300°C for 2 hours. The solid product after roasting is redispersed in 200ml deionized water, successively adds 1272g food-grade phosphoric acid (H 3 PO 4 Mass percent composition 85%), 305g silica sol (SiO 2 27% by mass), 1680g triethylamine (99.8% by mass of triethylamine), stirred at room temperature for 2h, and the formed homogeneous gel mixture was packed into a polytetrafluoro reactor, aged at 170°C for 16h, Crystallization at 200°C for 12 hours.

[0039]The reaction product was centrifuged, filtered, washed, dried at 100°C, and then calcined at 550°C for 3 hours to obtai...

Embodiment 2

[0048] Example 2 (Mg-SAPO-34)

[0049] Magnesium nitrate 25g (analytically pure) is dissolved in 50ml water and is made into solution for subsequent use, and 840g pseudo-boehmite (Al 2 o 3 Quality white powder content 67%) was dissolved in 200ml of deionized water and stirred evenly, then added to the aqueous solution of magnesium nitrate, stirred at room temperature for 2h, filtered, washed, dried, and roasted at 400°C for 5 hours. The solid product after roasting is redispersed in 200ml deionized water, successively adds 1272g food-grade phosphoric acid (H 3 PO 4 Percentage content 85%), 268g ethyl orthosilicate (SiO 2 mass percentage content 25%), 1080g diethylamine (diethylamine percentage content 99.8%), stir 2h at room temperature, the homogeneous gel mixture that forms is packed in the Teflon reactor, 60 ℃ aging 8h, 200 ℃ crystallization for 12 hours.

[0050] The reaction product was centrifuged, filtered, washed, dried at 160°C, and then calcined at 550°C for 3 h...

Embodiment 3

[0051] Example 3 (Zn-SAPO-34)

[0052] Dissolve 50g of zinc acetate (analytically pure) in 100ml of water to make a solution for later use, dissolve 568g of aluminum oxide (99% in mass content) in 200ml of deionized water and stir evenly, then add it to the aqueous solution of zinc acetate, stir at room temperature for 6h, filter , After washing and drying, bake at 500°C for 3 hours. The solid product after roasting is redispersed in 200ml deionized water, successively adds 1272g food-grade phosphoric acid (H 3 PO 4 Percentage 85%), 115g white carbon black (SiO 2 mass percentage content 90%), 1400g triethylamine (triethylamine percentage content 99.8%), tetraethylammonium hydroxide 202g (tetraethylammonium hydroxide 25%) stirred at room temperature 2h, the formed homogeneous condensation Put the glue mixture into a PTFE reactor, age at 130°C for 10 hours, and crystallize at 200°C for 20 hours.

[0053] The reaction product was centrifuged, filtered, washed, dried at 120° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com