Nanometer palladium catalyst for hydrogenation of anthraquinone and preparation method thereof

The technology of nano-palladium and catalyst is applied in the field of nano-palladium catalyst for hydrogenation of anthraquinone and the field of preparation, which can solve the problems of low hydrogenation efficiency, large amount of palladium and the like, and achieves environmental protection in preparation process, mild conditions, and stable performance for repeated reuse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 3g of Gardenia (the dry weight of Gardenia and deionized water is 1:40) soak in 120ml of water at 100°C for 10min, take 0.1g of palladium chloride and make a 0.5mmol / L solution with the above extract of Gardenia, at 80°C After acting in a water bath for 36 hours and evaporating to dryness at 60° C. in vacuum, a gardenia in situ reduction-supported nanocatalyst was obtained, and the palladium loading relative to the gardenia extract was 1.2% by weight. Take 30mg of catalyst and put it into a fluidized bed reactor with 10ml of ethanol and 15ml of anthraquinone working solution, hydrogenate at 65°C for 1.75h, hydrogen flow rate is 30ml / min, oxidation is 45min, air flow rate is 30ml / min, hydrogenation efficiency is 9.3g / min L.

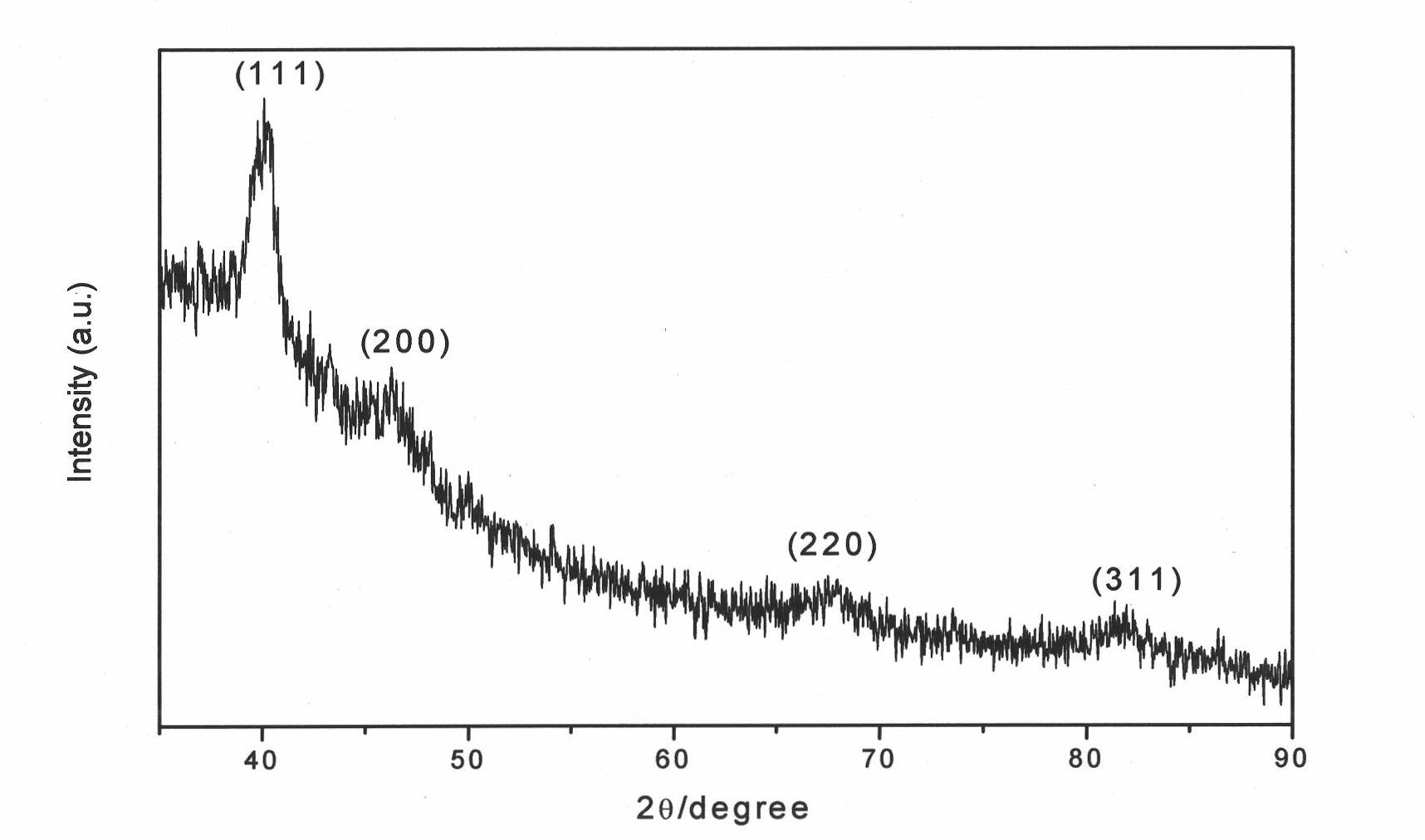

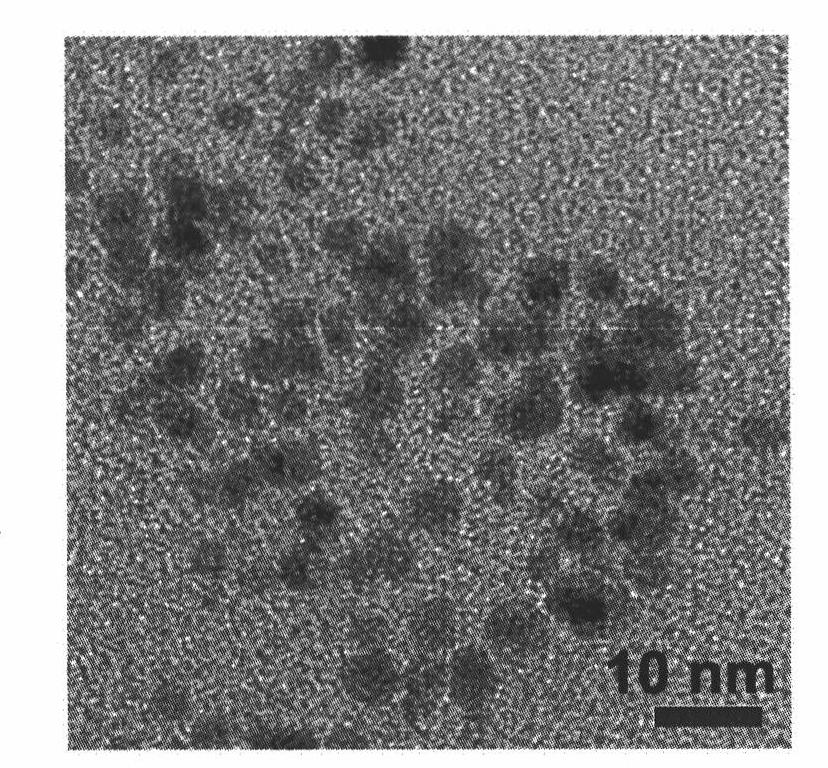

[0027] The XRD spectrum of the nano-palladium catalyst supported on the gardenia is shown in figure 1 , the diffraction peaks from left to right correspond to (111), (200), (220) and (311) palladium crystal planes, respectively. The electron ...

Embodiment 2

[0029] Take 2g of Gardenia (the dry weight of Gardenia and deionized water is 1:50) soak in 100ml of water at 90°C for 10min, take 0.1g of palladium chloride and use the above-mentioned Gardenia extract to make a 1 mmol / L solution, and put it in a water bath at 90°C After being neutralized for 24 hours and evaporated to dryness under vacuum at 60° C., a gardenia in situ reduction-supported nanocatalyst was obtained, and the palladium loading was 2.4% relative to the mass percentage of the gardenia extract. Take 30mg of catalyst and add it to a fluidized bed reactor with 10ml of ethanol and 10ml of anthraquinone working solution, hydrogenate at 50°C for 1.5h, hydrogen flow rate is 40ml / min, oxidation is 45min, air flow rate is 50ml / min, hydrogenation efficiency is 12.8g / L.

Embodiment 3

[0031] Take 5g of Gardenia (the dry weight of Gardenia and deionized water is 1:20) soak in 100ml of water at 100°C for 10min, take 0.1g of palladium chloride and make a 0.5mmol / L solution with the above extract of Gardenia, 60°C After acting in a water bath for 48 hours, and evaporating and drying in a vacuum at 60° C., a gardenia in situ reduction-supported nanocatalyst was obtained, and the palladium loading was 1.2% relative to the mass percentage of the gardenia extract. Take 25mg of catalyst and put it into a fluidized bed reactor with 10ml of ethanol and 10ml of anthraquinone working solution, hydrogenate at 65°C for 1h, hydrogen flow rate is 40ml / min, oxidation is 30min, air flow rate is 30ml / min, hydrogenation efficiency is 9.0g / min L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com