Modification method for silicon dioxide aerogel

A technology of silica and airgel, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

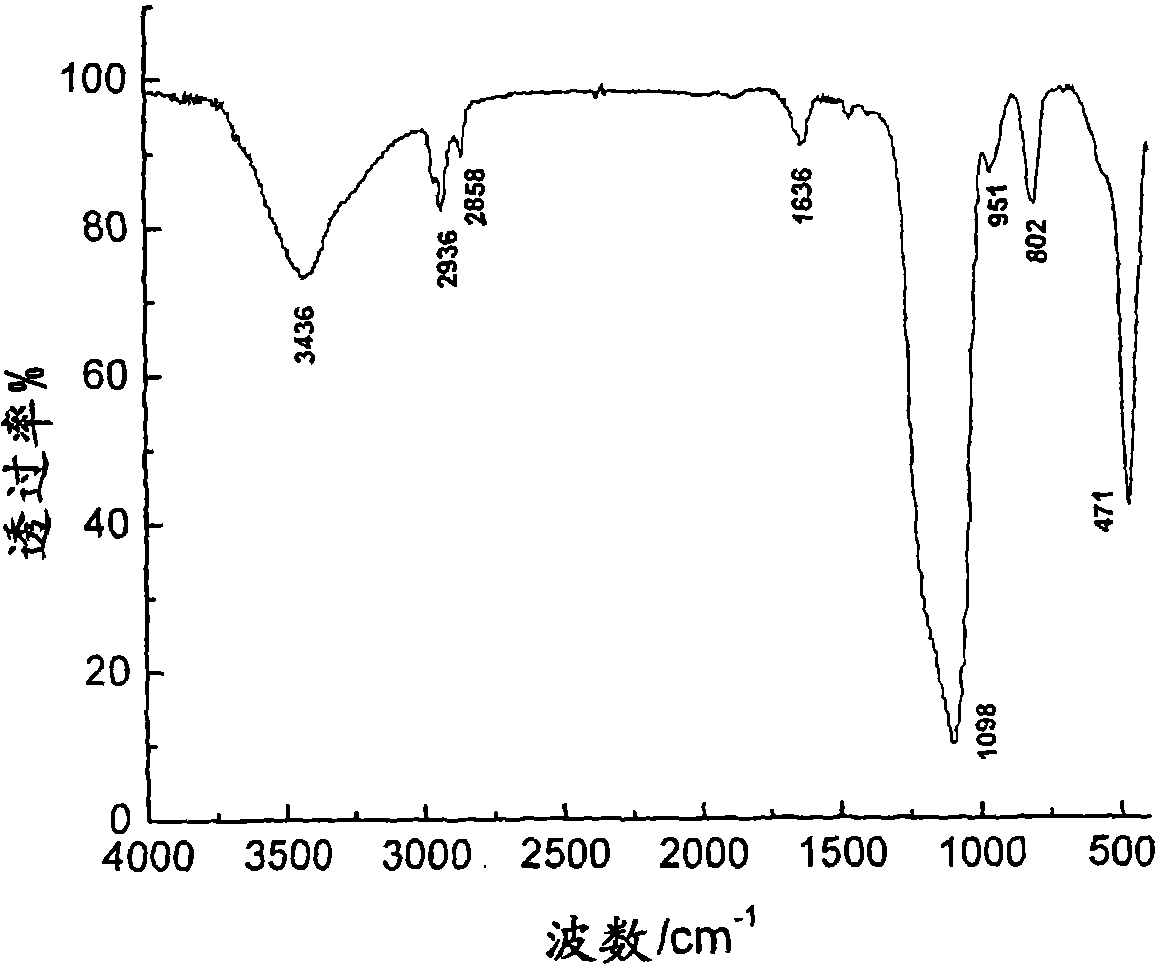

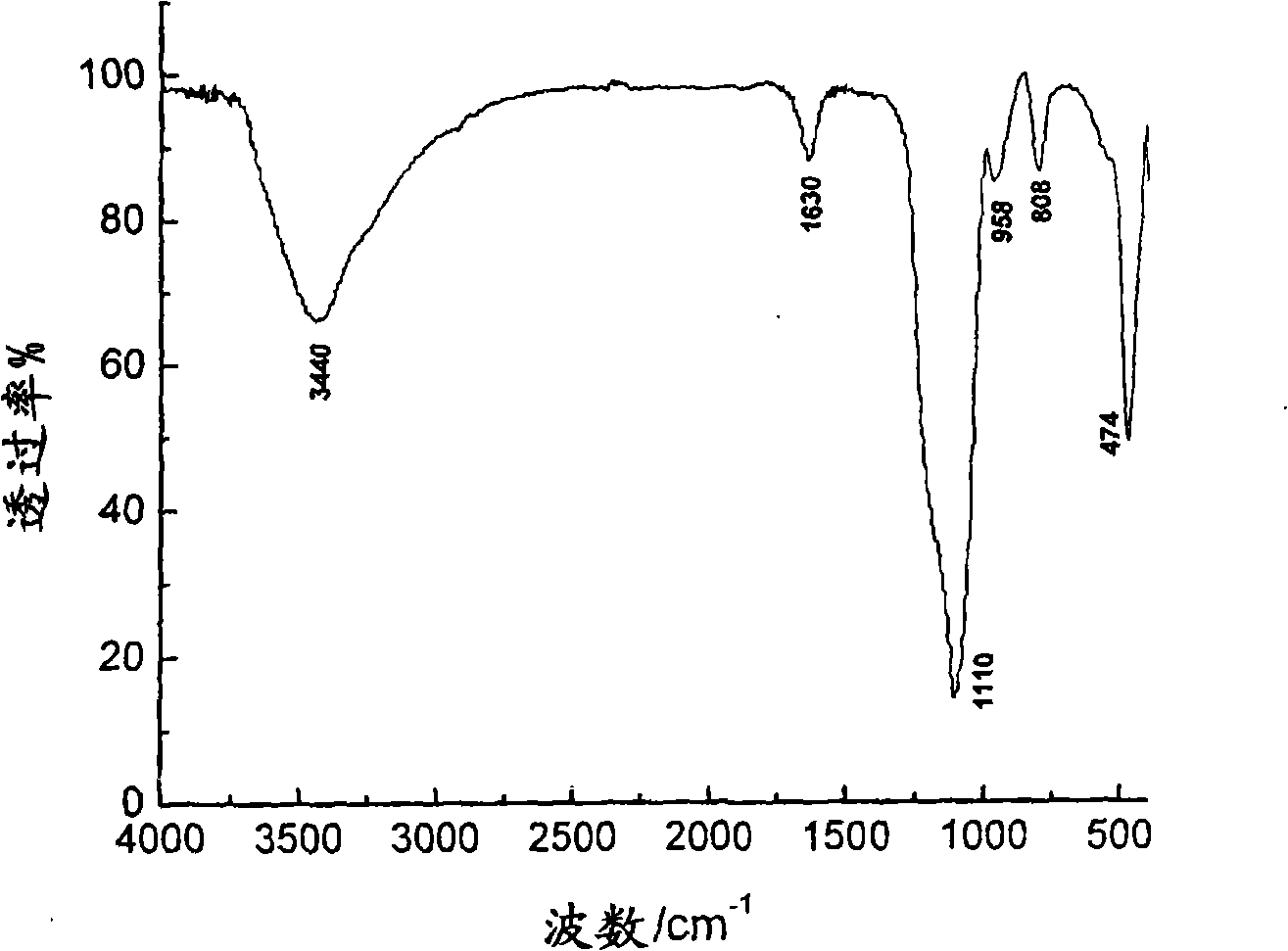

[0016] According to a specific embodiment of the present invention, the specific steps of dehydration modification are as follows:

[0017] 1. Filtering or press-filtering the synthetic or purchased silica wet gel into a wet filter cake with a water content of 80-95% (mass).

[0018] 2. Submerging the wet filter cake in C4-C10 aliphatic alcohol, the volume ratio of the amount of alcohol added to the water content in the wet filter cake is: (0.1-10):1. Stir the heterogeneous system until homogeneous.

[0019] 3. The multi-phase system is continuously stirred and heated. When the azeotropic temperature of water and alcohol is reached, the water and alcohol are azeotropically distilled out at a constant volume ratio, and the temperature of the system remains unchanged. During the heating process, the liquid level is always kept higher than the solid phase , if not enough, continue to add alcohol. After the obtained steam is condensed and allowed to stand for stratification, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com