Cu-Fe-Co base catalyst used for synthesizing low carbon alcohol by utilizing synthesis gas as well as preparation method and application thereof in low carbon alcohol synthesizing process by virtue of synthesis gas

A cu-fe-co and catalyst technology, applied in the chemical industry, can solve the problems of high production cost and low alcohol selectivity, and achieve the effects of low cost, improved selectivity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] By expression Cu 25 Fe 15 co 5 K 2 / (SiO 2 ) 58 To prepare the catalyst, take 10.0g of 30-100 mesh microsphere silica gel, configure Cu, Fe, Co, K nitrate aqueous solution (impregnated with equal volume) according to the ratio of the above expression, impregnate at room temperature for 4 hours, then bake at 200°C Dry. Then the temperature was raised to 400°C at a rate of 1.0°C / min and fired for 8 hours, and then cooled to room temperature naturally.

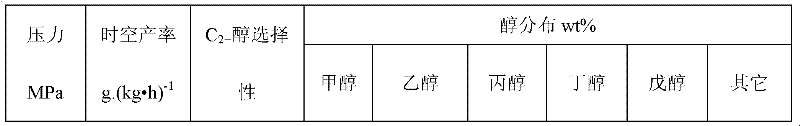

[0026] The prepared catalyst was moved into the reactor, and H 2 Reduce at 400°C for 8 hours, then switch to syngas at a pressure of 1.5-10.0MPa, a temperature of 300°C, and a space velocity of 6000h -1 , H 2 / CO=2, the liquid phase product was collected in an ice-water bath, and the product composition was analyzed by gas chromatography. The obtained results are shown in Table 1:

[0027] Table 1

[0028]

[0029]

Embodiment 2

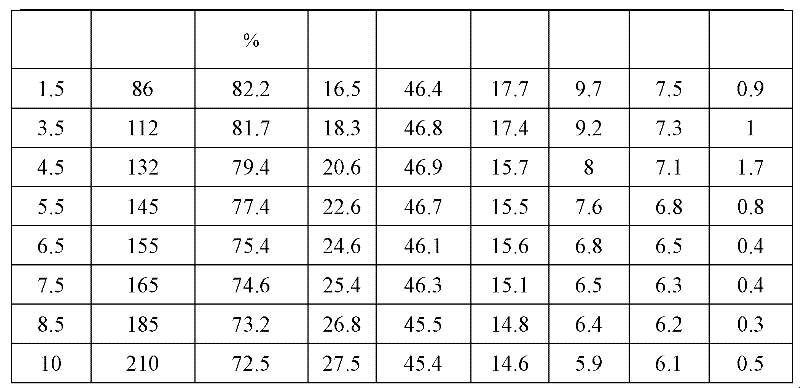

[0031] By expression Cu 20 Fe 20 co 5 Ce 2 / (SiO 2 ) 53 Prepare catalyst, get 10.0g 30~100 order microsphere silica gel, configure the oxalate of Cu, Fe, Co, Ce to contain ethanol 10% aqueous solution (with equal volume impregnation) according to above-mentioned expression ratio, all the other are with embodiment 1. Pressure 5.5MPa, temperature 210-450℃, space velocity 6000h -1 , H 2 / CO=2, the obtained results are shown in Table 2:

[0032] Table 2

[0033]

Embodiment 3

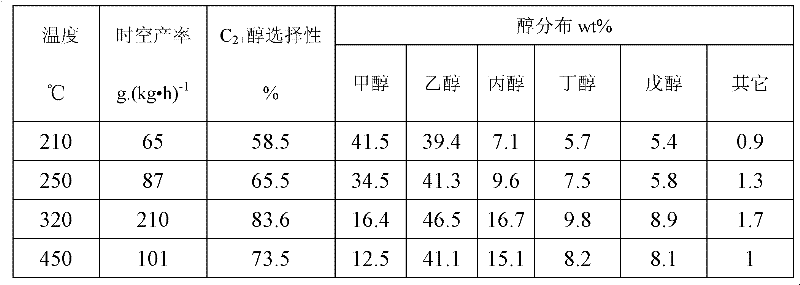

[0035] By expression Cu 25 Fe 25 co 3 mn 2 / (SiO 2 ) 45Prepare catalyst, get 10.0g 30~100 order microsphere silica gels, configure Cu, Fe, Co, Mn acetate containing 30% acetone aqueous solution (with equal volume impregnation) according to the ratio of the above expression, all the other are the same as in Example 1. Pressure 5.5MPa, temperature 350℃, space velocity 500~14000h -1 , H 2 / CO=2, the obtained results are as follows:

[0036] table 3

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com