Natural nanomaterial attapulgite-supported cu-fe-based multi-component catalyst and its preparation method and application in the synthesis of low-carbon alcohols

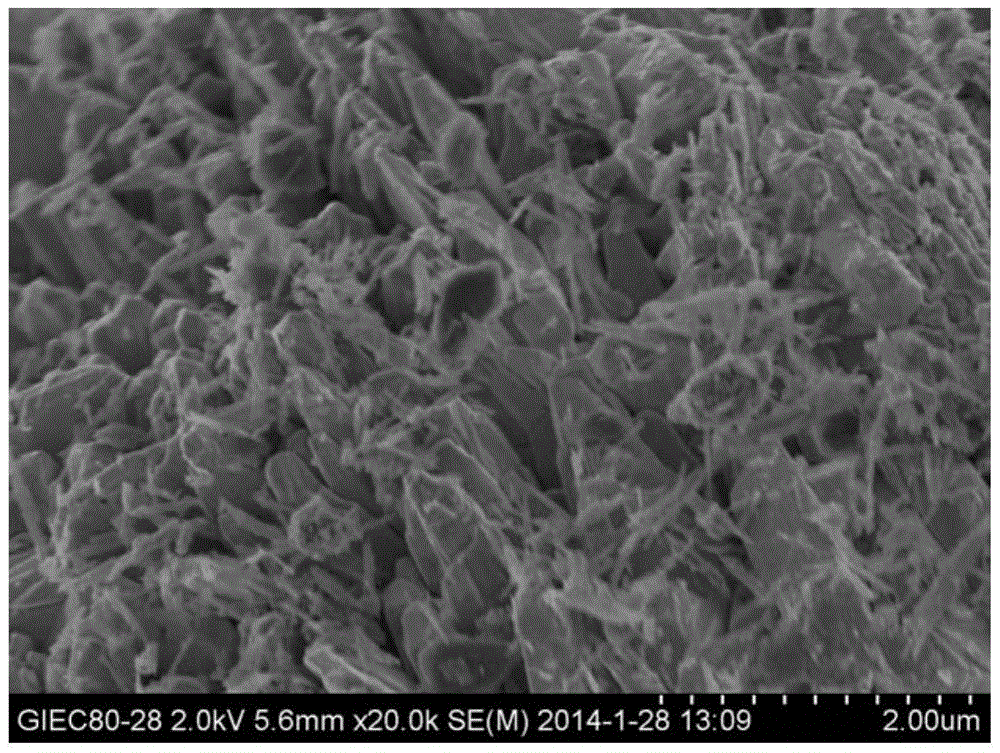

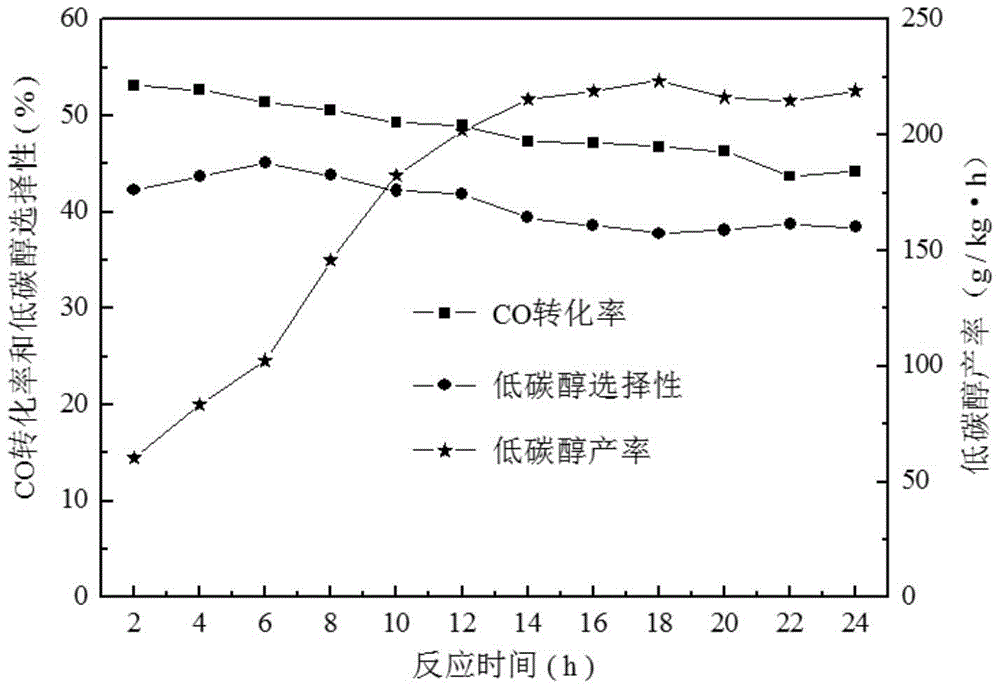

A technology of attapulgite and nanomaterials, which is applied in the preparation of hydroxyl compounds, chemical instruments and methods, and the preparation of organic compounds. It can solve problems that have not been reported yet, and achieve easy industrial scale-up production, large specific surface area, and improved low-carbon The effect of alcohol selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

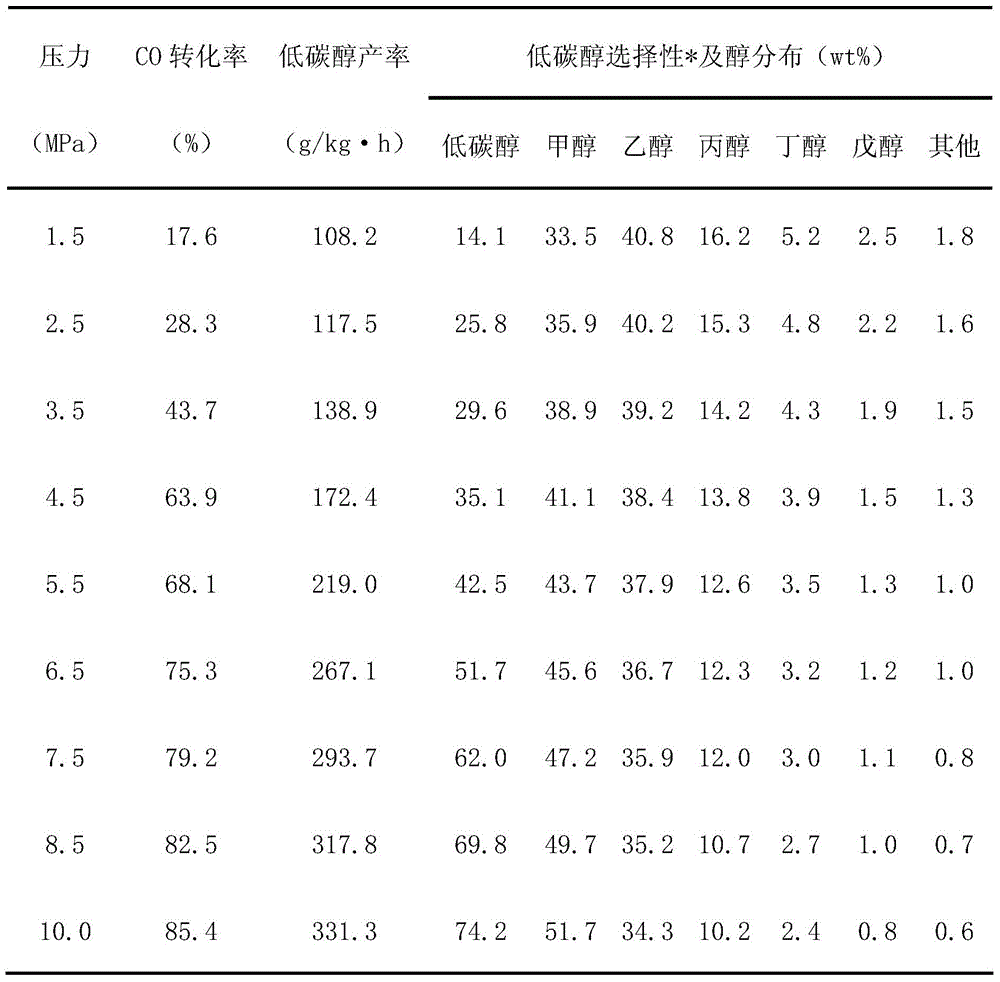

Examples

Embodiment 1

[0025] (1) Add 500mL water into a three-necked flask and heat it in a water bath to 80°C, then add 100g of dry natural attapulgite powder, stir at a constant temperature for 120min, then let it stand, discard the upper layer of clear water and bottom sand particles, and filter the middle layer of slurry and dry it , to obtain rinsed attapulgite.

[0026] (2) adopt 150mL, 3wt% sulfuric acid (H 2 SO 4 ) solution to acid-modify the rinsed attapulgite powder: add 80mL of water into a three-necked flask and heat it to 60°C in a water bath, then add 30g of rinsed attapulgite powder (>100 mesh) and stir at a constant temperature, and finally add 67.5mL of water h 2 SO 4 Solution (configuration 150mL, total concentration is 3wt%H 2 SO 4 solution, adding 98wt% H 2 SO 4 The volume is 2.5mL, so the water volume at this time is 150-80-2.5=67.5mL), continue to stir and react at a constant temperature for 3.5h, after the end, perform suction filtration, wash until neutral, and dry to...

Embodiment 2

[0033] (1) Add 800mL water into a three-necked flask and heat it in a water bath to 50°C, then add 80g of dry natural attapulgite powder, stir at a constant temperature for 80 minutes, let it stand, discard the upper layer of clear water and bottom sand particles, and filter the middle layer of slurry and dry it. , to obtain rinsed attapulgite.

[0034] (2) Using 320mL, 21wt% nitric acid (HNO 3 ) solution to acid-modify the rinsed attapulgite powder: add 120mL of water into a three-necked flask and heat it to 75°C in a water bath, then add 40g of rinsed attapulgite powder (>100 mesh) and stir evenly at a constant temperature, and finally add 133.9mL of water-prepared HNO 3 Solution (configuration 320mL, total concentration is 21wt% HNO 3 solution, adding 68wt% HNO 3 The volume is 66.1mL, so the water volume at this time is 320-120-66.1=133.9mL), continue to stir and react at a constant temperature for 5h, after the end, perform suction filtration, wash until neutral, and dr...

Embodiment 3

[0041] (1) Add 720mL of water into a three-necked flask and heat it to 70°C in a water bath, then add 90g of dry natural attapulgite powder, stir at a constant temperature for 60 minutes, let it stand, discard the upper layer of clear water and bottom sand particles, and filter the middle layer of slurry and dry it. , to obtain rinsed attapulgite.

[0042] (2) adopt 350mL, 15wt% phosphoric acid (H 3 PO 4 ) solution to acid-modify the rinsed attapulgite powder: add 150mL of water into a three-necked flask and heat it to 90°C in a water bath, then add 70g of rinsed attapulgite powder (>100 mesh) and stir evenly at a constant temperature, and finally add 161.7mL of water-prepared h 3 PO 4 Solution (configuration total concentration is 15wt%H 3 PO 4 solution, add 85wt% H 3 PO 4 The volume is 38.3mL, so the volume of water at this time is 350-150-38.3=161.7mL), continue to stir and react at a constant temperature for 2 hours, after the end, perform suction filtration, wash u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com