Preparation method of catalyst for selective hydrogenation of alkyne and alkadiene

A hydrogenation catalyst and diene technology, which is applied in chemical instruments and methods, hydrocarbons, hydrocarbon purification/separation, etc., can solve the problems of rapid loss of palladium in the active center, poor stability of catalyst activity, catalyst coking and deactivation, etc. Achieve the effects of low surface acid content, suitable hydrogenation activity and long activity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

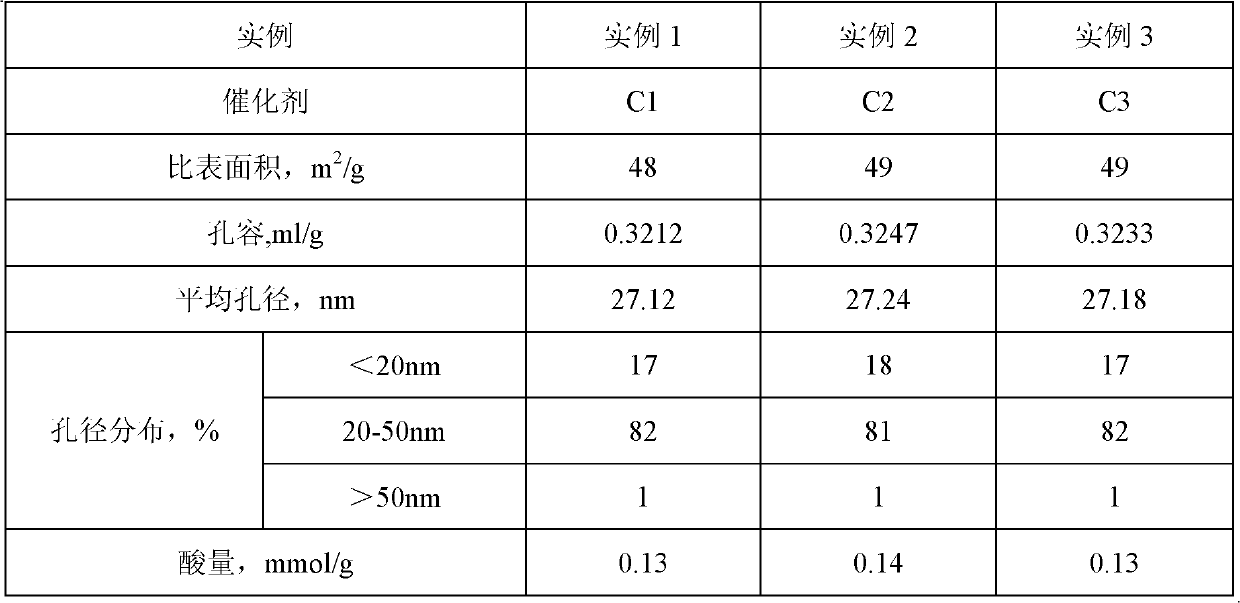

Embodiment 1

[0024] Get macroporous aluminum oxide powder 300g altogether, wherein 150g is used for preparing acidic sol, the preparation method of acidic sol is to add concentrated nitric acid 60ml, water 50ml and 150g aluminum oxide powder are fully stirred and mixed into sol-like stand-by; Stir and mix the remaining 150g of alumina and 60g of rutile titanium dioxide powder, 40g of magnesium oxide powder, 100g of zinc oxide powder, and 25g of turnip powder in a container for use; mix 25g of polyethylene glycol (400) 1. Mix 25g of citric acid and 150ml of aqueous solution evenly before use; knead the above two kinds of ready-to-use powders and a kind of ready-to-use mixed solution in the extruder for 6 times, and after kneading, form a cylindrical shape with a diameter of Ф1.8mm. The carrier was dried in a vacuum drying oven at 120°C for 4 hours, firstly heated to 450°C in a muffle furnace at 5°C / min, and stayed at 450°C for 2 hours, then raised to 950°C at 5°C / min, and heated at 950°C It...

Embodiment 2

[0027] The preparation method of carrier Z1 is the same as example 1.

[0028] Weigh 0.052g of gold chloride, 0.079g of bismuth nitrate, 0.106g of cerium nitrate, and 2g of soluble starch and dissolve them in 60ml of water at 100°C. After stirring for 2 hours, impregnate them on a 100g Z1 carrier for 2 hours. After internal drying for 4 hours, place it in a muffle furnace for roasting. The roasting procedure is to raise the temperature at 3°C / min to 450°C and roast for 4h to obtain the intermediate catalyst CZ2. Then weigh 0.333g of palladium chloride and 2g of starch and dissolve them in 60ml of 100°C water , stirred for 2 hours and impregnated on the intermediate catalyst CZ2. The impregnation time was 2 hours. After the impregnation was completed, it was dried in an oven for 4 hours and then placed in a muffle furnace for roasting. The roasting procedure was to raise the temperature at 3 °C / min to 500 °C for 4 h to obtain the catalyst. C2.

Embodiment 3

[0030] The preparation method of carrier Z1 is the same as example 1.

[0031] Weigh 0.052g of gold chloride, 0.079g of bismuth nitrate, 0.106g of cerium nitrate, 0.0787g of silver nitrate, and 2g of soluble starch and dissolve them in 60ml of water at 100°C. After stirring for 2 hours, impregnate them on a 100g Z1 carrier for 2 hours. After impregnation, dry it in an oven for 4 hours and then place it in a muffle furnace for roasting. The roasting procedure is to heat up to 450 °C at 3°C / min and roast for 4h to obtain the intermediate catalyst CZ2, then weigh 0.333g of palladium chloride and 2g of starch and dissolve in 60ml of water at 100°C, stirred for 2 hours, then impregnated on the intermediate catalyst CZ3, the impregnation time is 2h, after the impregnation is completed, it is dried in an oven for 4 hours, and then placed in a muffle furnace for roasting, the roasting program is to increase the temperature at 3°C / min to 500 C3 was calcined at ℃ for 4h to obtain cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com