Synthesis method of MFI molecular sieve nanosheet

A synthesis method and technology of nanosheets, applied in the direction of molecular sieve characteristic polycrystalline silicon, nanotechnology, silicon compounds, etc., can solve problems such as limiting application prospects, corroding devices, environmental pollution, etc., and achieve simple material types and good parallelism Sexuality and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a kind of synthetic method of MFI molecular sieve nanosheet, and its concrete steps are:

[0041] Step 1, the material ratio of the raw materials required for the synthesized MFI molecular sieve nanosheets is: SiO 2 :xAl 2 o 3 :yR:mH 2 O, wherein: R is a templating agent, 0

[0042] Step 2. Weigh the required amount of template agent R, silicon source and a certain amount of water and stir evenly to form a synthetic sol.

[0043] Step 3, adding an aluminum source to the above-mentioned synthetic sol, and stirring evenly;

[0044] Step 4. Add a fluorine-free acid reagent to the above synthetic sol, adjust the pH value of the system to 7.0-9.5, and stir and pre-crystallize at 40-100°C for 1-50 hours to obtain a synthetic mother liquor; the acid reagent can be Inorganic acids such as sulfuric acid and hydrochloric acid may also...

Embodiment 1

[0059] Synthetic ratio: SiO 2 :Al 2 o 3 :R:H 2 O=1:0.01:0.15:25, wherein R is tetrapropylammonium hydroxide.

[0060] Synthesis steps: drop tetrapropylammonium hydroxide and ethyl orthosilicate into water respectively, mix and stir for 4 hours, then add pseudo-boehmite, use H 2 SO 4 Adjust the pH value of the system to about 8.5, uniformly stir and pre-crystallize at 90°C for 12 hours, then put it into a polytetrafluoroethylene-lined reactor, crystallize at 95°C for 4 days, and cool to room temperature. The resulting mixture is subjected to solid-liquid separation and washing. The solid phase product was dried at 80°C to obtain the final product.

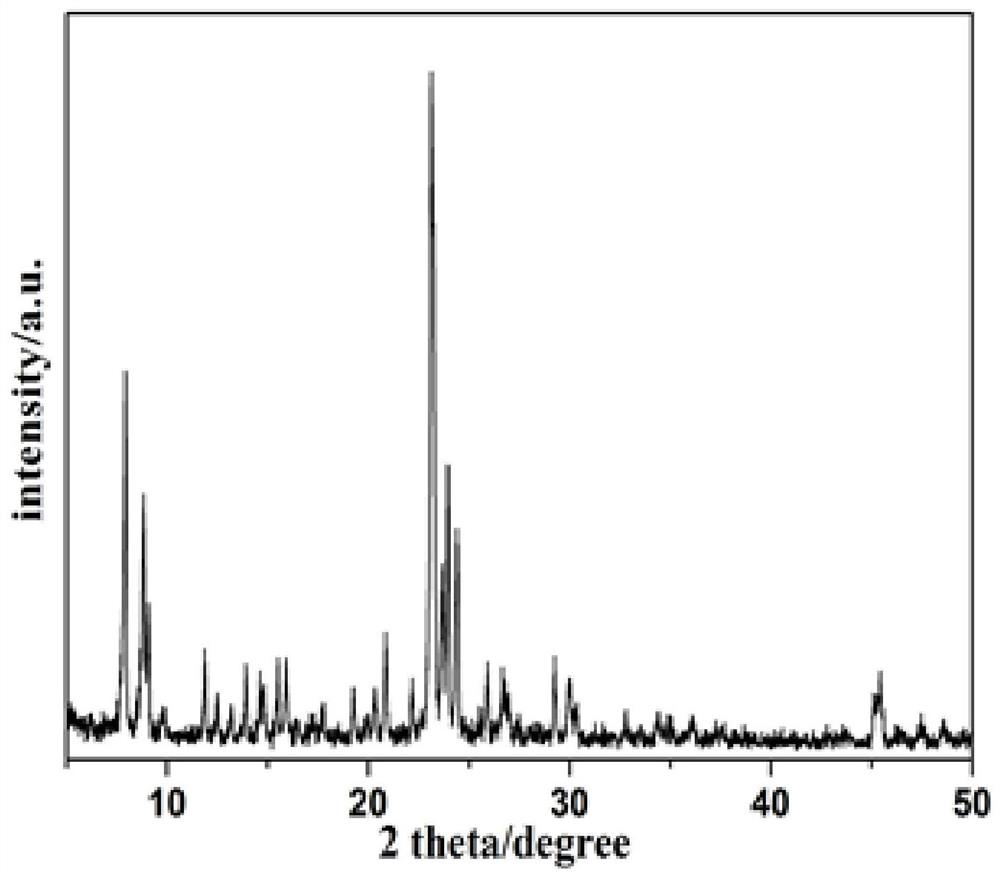

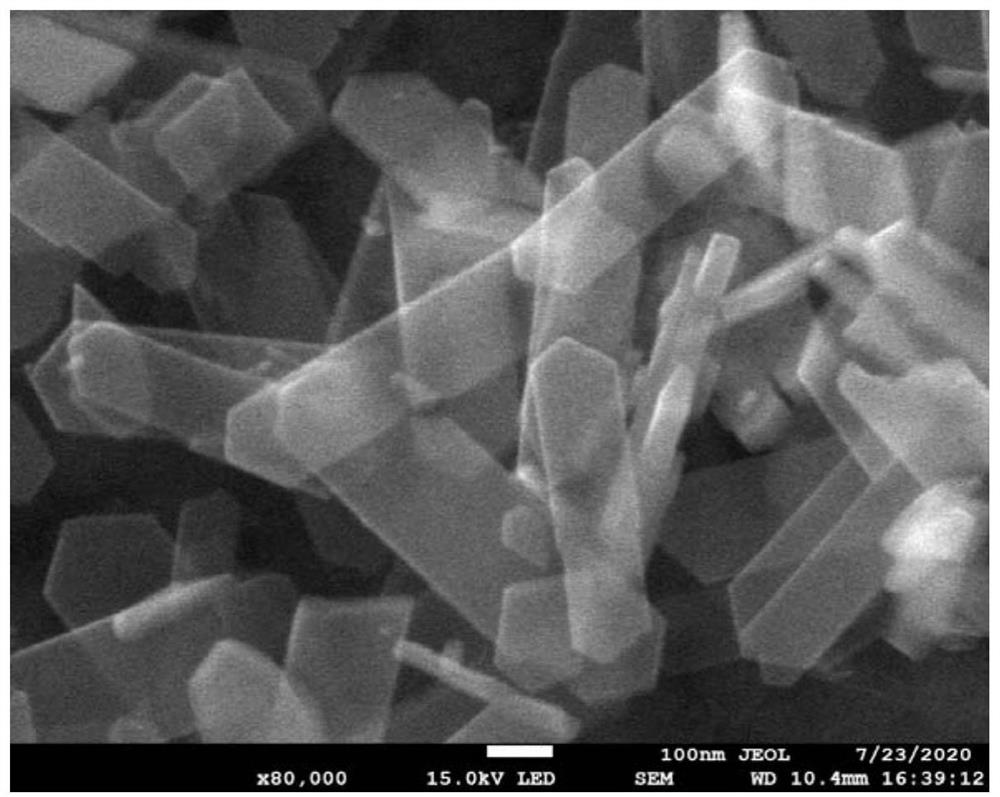

[0061] figure 1 is the XRD spectrum of the obtained product, it can be seen that the product has typical characteristic diffraction peaks of the MFI structure, and the crystallinity is relatively high. figure 2 It is the SEM photo of the obtained product, it can be seen that the product is in the shape of a sheet, with a thi...

Embodiment 2

[0063] Synthesize MFI molecular sieve nanosheets according to the raw materials and steps in Example 1, the difference is that the synthesis ratio is: SiO 2 :R:H 2 O=1:0.15:25; that is, no aluminum source is added during the synthesis process. After the synthetic mother liquor was put into the reactor, it was crystallized at 90°C for 4 days, and the resulting mixture was separated from solid and liquid and dried to obtain the final solid phase product.

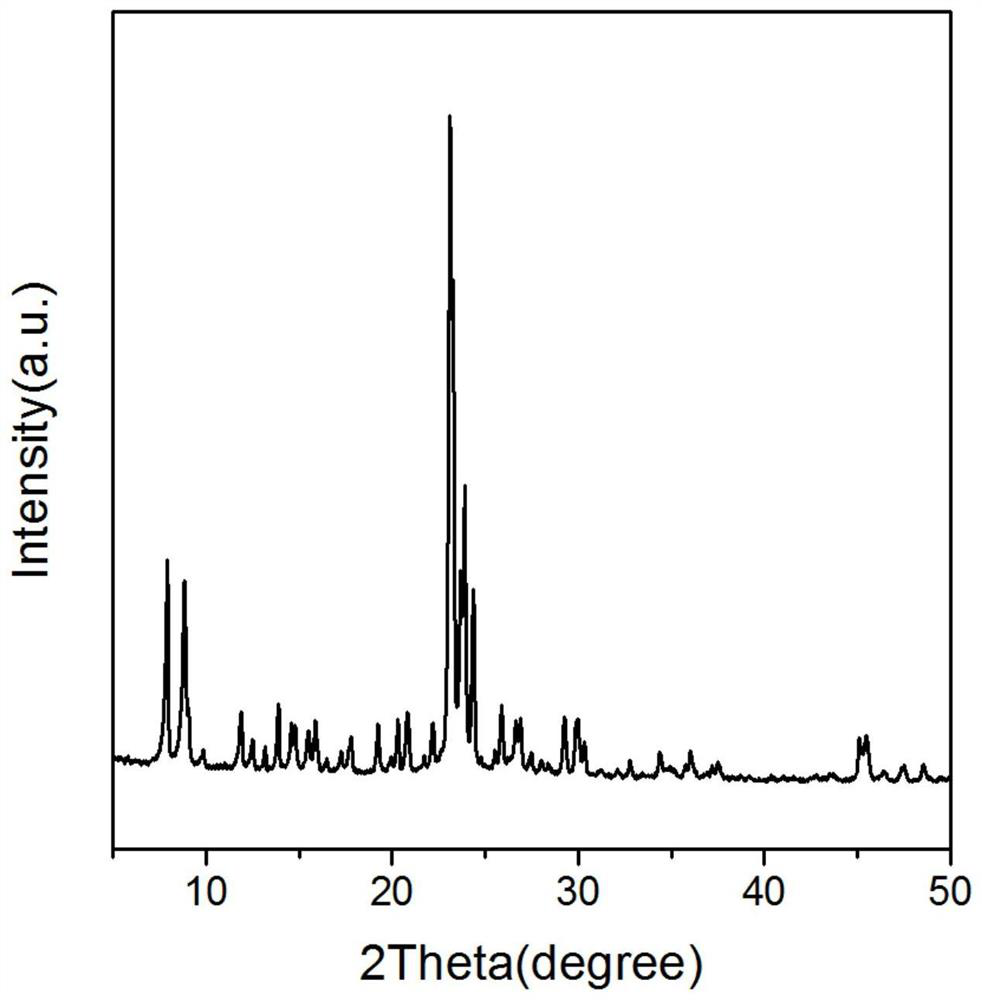

[0064] image 3 is the XRD spectrum of the resulting product, as can be seen, the product is a molecular sieve with MFI structure; Figure 4 The SEM photo of the obtained sample shows that the sample is a MFI molecular sieve nanosheet with a thickness of about 50-80 nm and a length of about 1.0 μm. , about 0.2µm in width

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com