Preparation method of neodymium calcium aluminate

A neodymium calcium aluminate and nitrate technology, applied in chemical instruments and methods, rare earth metal compounds, inorganic chemistry and other directions, can solve the problems of high preparation temperature and long preparation time of neodymium calcium aluminate, and overcome the long synthesis cycle, The effect of good quality and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The present embodiment provides a kind of preparation method of neodymium calcium aluminate, comprises the following steps:

[0013] (1) Press CaNdAlO 4 The stoichiometric ratio of the metal elements in the medium, respectively weighed the compounds containing Ca, Nd, Al as raw materials, prepared to contain Ca 2+ 、Nd 3+ and Al 3+ The mixed solution of nitrate; Add organic fuel and complexing agent to the above mixed solution of nitrate, the organic fuel is at least one of urea, citric acid and glycine, and the Ca in the mixed solution of organic fuel and nitrate 2+ The molar ratio of the organic fuel is 1-6:1. If the amount of organic fuel added is too much, the purity of the product will be affected; if the amount of organic fuel added is too small, the fuel will be insufficient and the reaction will be insufficient; the complexing agent is B Glycol and / or polyethylene glycol, and the molar ratio of complexing agent and organic fuel is 4:1, if the adding amount of ...

Embodiment 1

[0021] The present embodiment provides a kind of preparation method of neodymium calcium aluminate, comprises the following steps:

[0022] (1) Weigh 1 mol of Ca(NO 3 ) 2 4H 2 O and 1mol of Al(NO 3 ) 3 9H 2 O was added to No. 1 beaker, and deionized water was added to the beaker and stirred to completely dissolve the contents in the beaker; weigh 0.5mol of Nd 2 o 3 Add to No. 2 beaker, then add excess concentrated nitric acid, wait for Nd 2 o 3 After complete dissolution, Nd(NO 3 ) 3 Solution, stir and mix the solutions in No. 1 beaker and No. 2 beaker evenly to obtain Ca 2+ 、Nd 3+ and Al 3+ nitrate mixed solution; then weigh 3mol urea and 12mol ethylene glycol and add the above mixed solution, stir and mix evenly for subsequent use;

[0023] (2) Turn on the resistance furnace and set the temperature to 800°C. After the resistance furnace heats up to 800°C, keep the temperature constant, then place the mixed solution in step (1) in a porcelain crucible and put it ...

Embodiment 2

[0026] The same raw materials and method as in Example 1 were used to prepare neodymium calcium aluminate, the difference being that the combustion temperature of the mixed liquid was 900°C.

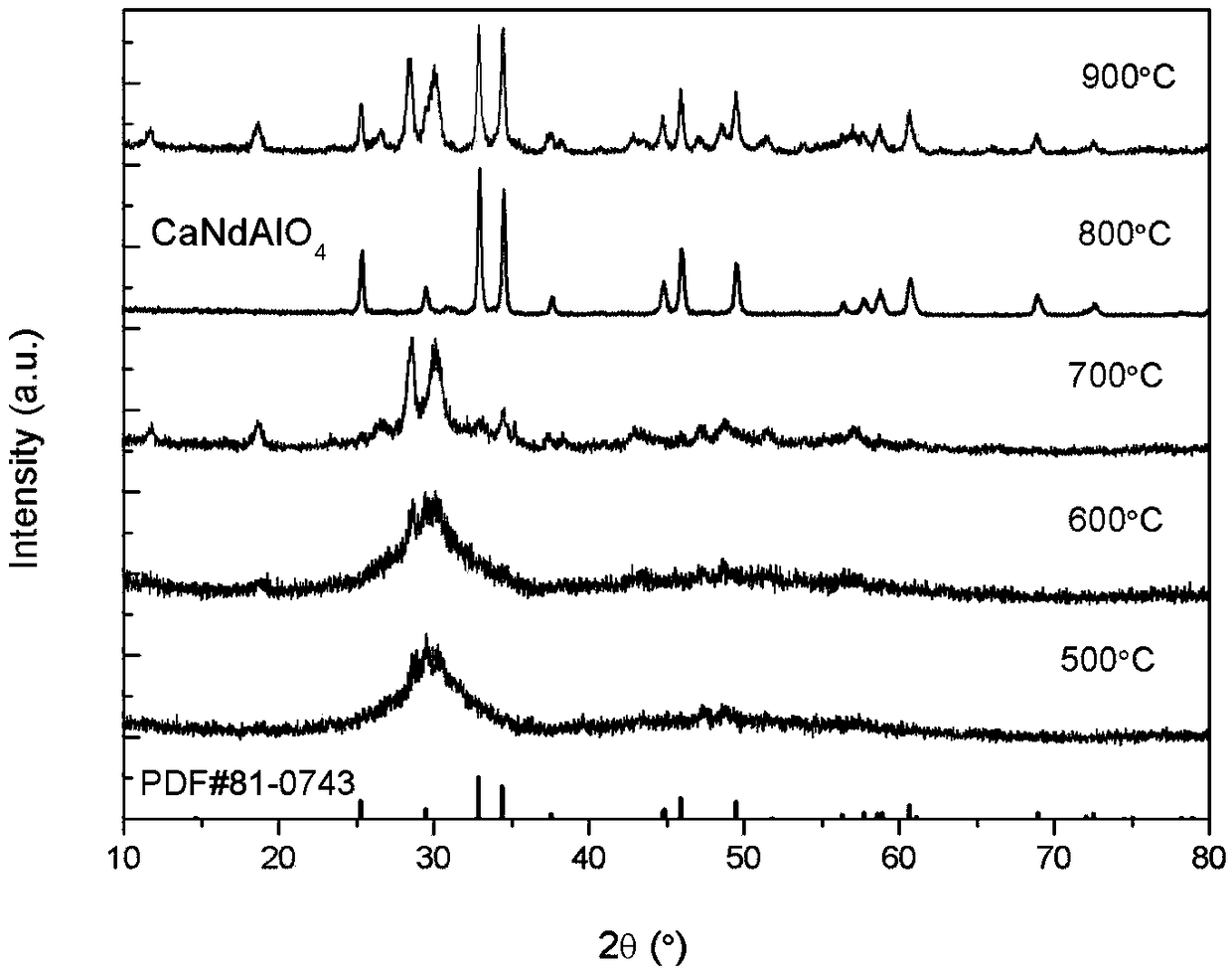

[0027] The XRD of the synthetic product of this embodiment sees figure 1 ,figure 1 In , the material prepared in this example is marked as "900°C". Control CaNdAlO 4 It can be seen from the PDF card (PDF#81-0743) that the product is mainly CaNdAlO 4 , but contains a large number of second-phase crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com