Method for synthesizing ultrathin ZSM-5 molecular sieve nanosheets under low temperature and normal pressure

A technology of ZSM-5 and molecular sieve, which is applied in the direction of nanotechnology, crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., to achieve good catalytic activity, simplify hydrothermal synthesis steps, and controllable size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Synthesis method: Dissolve 14.45g tetrapropylammonium hydroxide (25%) and 33.3g silica sol (40%) in 10ml water, mix and stir for 12h, then add 0.92g aluminum sol, 6.58g ammonium fluoride, 80°C Stir evenly for pre-crystallization for 12 hours, then put it into a polytetrafluoroethylene-lined stainless steel reactor for medium crystallization at 80°C for 36 hours, then cool to room temperature, wash with deionized water, and dry at 80°C to obtain the final product.

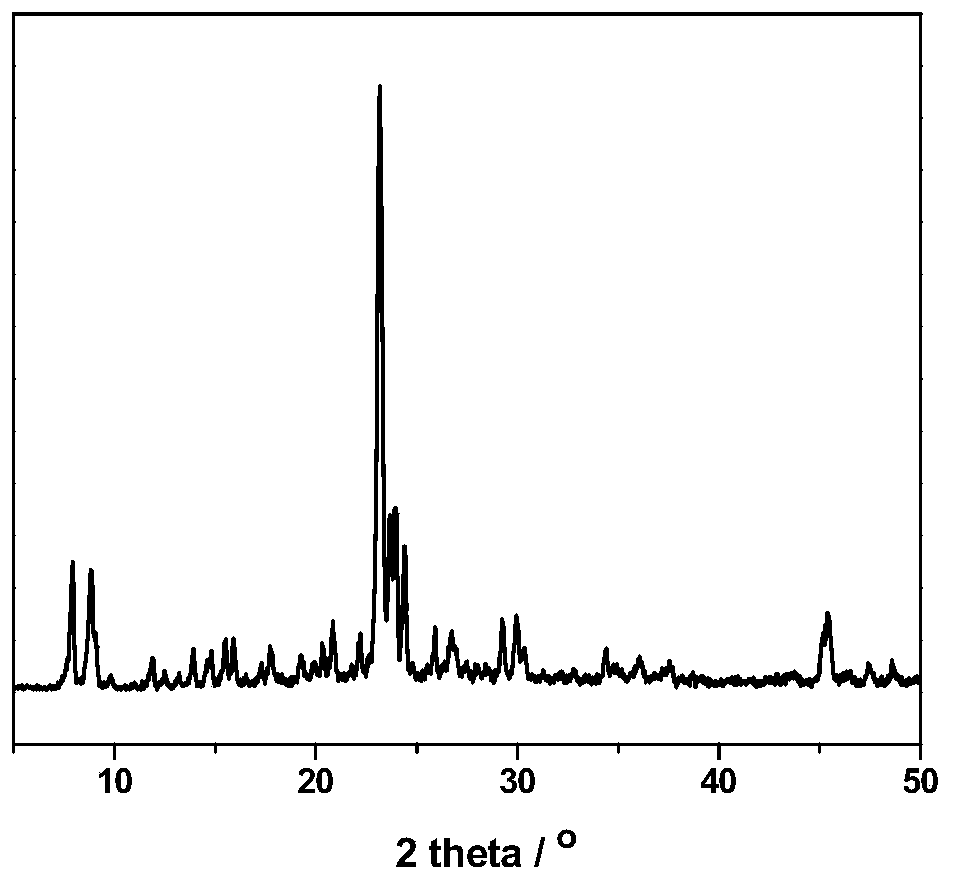

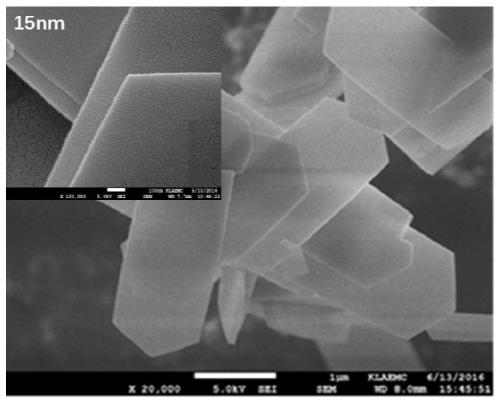

[0045] figure 1 It is the XRD spectrogram of the product obtained in Example 1, it can be seen that the product has the characteristic diffraction peak of the MFI structure, and has a higher crystallinity. figure 2 It is the SEM spectrogram of the product obtained in Example 1. It can be seen that the sample presents a sheet-like morphology with a thickness of about 15 nm.

Embodiment 2

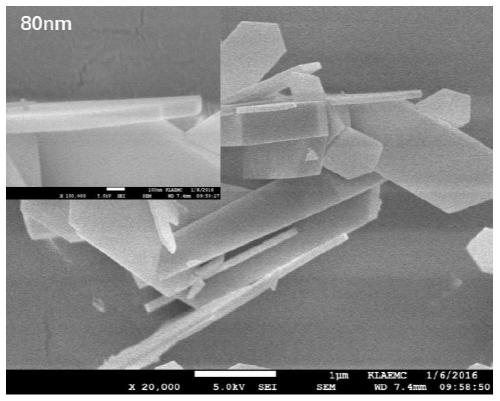

[0047] Using the same conditions as in Example 1, change the template agent to ethylenediamine, the dosage is 3.9g, stir evenly at 80°C for pre-crystallization for 12h, and then put it into a stainless steel reactor lined with polytetrafluoroethylene at 80°C Mesocrystallization for 36 hours, cooled to room temperature, washed with deionized water, and dried at 80°C to obtain the final product. The SEM spectrum shows that the sample presents a sheet-like morphology, and the thickness of the nanosheet is about 80nm.

Embodiment 3

[0049] Using the same conditions as in Example 1, change the fluorine source to ammonium hexafluorosilicate, the dosage is 3.9g, stir evenly at 80°C for pre-crystallization for 12h, and then put it into a stainless steel reactor lined with polytetrafluoroethylene at 80°C Crystallize for 36 hours, then cool to room temperature, wash with deionized water, and dry at 80°C to obtain the final product. to get the final product. The SEM image shows that the sample presents a sheet-like morphology, and the thickness of the nanosheet is about 60nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com